-

×

Dynabrade 32014 Filter Cage (for models 61204 and 614205)

1 × $103.52

Dynabrade 32014 Filter Cage (for models 61204 and 614205)

1 × $103.52 -

×

Dynabrade 78024 3/4" W x 18" L Coarse NWN DynaBrite Belt, 10/pack

10 × $6.48

Dynabrade 78024 3/4" W x 18" L Coarse NWN DynaBrite Belt, 10/pack

10 × $6.48 -

×

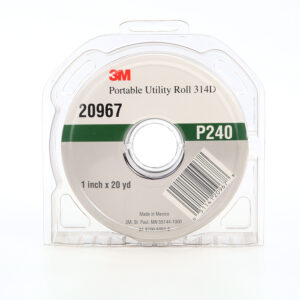

3M 20967, Portable Utility Cloth Roll 314D, P240 J-weight, 1 in x 20 yd, 7010290604

5 × $16.22

3M 20967, Portable Utility Cloth Roll 314D, P240 J-weight, 1 in x 20 yd, 7010290604

5 × $16.22 -

×

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.37

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.37 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $24.56

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $24.56 -

×

Dynabrade 11218 Contact Arm Ass'y, 5/8" Dia. x 3/8" W, Rubber Wheel, with 1/2" W Platen

1 × $69.58

Dynabrade 11218 Contact Arm Ass'y, 5/8" Dia. x 3/8" W, Rubber Wheel, with 1/2" W Platen

1 × $69.58 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89 -

×

Dynabrade 79171 1" W x 30" L 80 Grit Ceramic DynaCut Belt, 50/pack

50 × $7.82

Dynabrade 79171 1" W x 30" L 80 Grit Ceramic DynaCut Belt, 50/pack

50 × $7.82 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,493.91

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,493.91 -

×

Dynabrade 84852 3" x 4" Fine Foam, Extreme Orange, 24 per pack

24 × $1.20

Dynabrade 84852 3" x 4" Fine Foam, Extreme Orange, 24 per pack

24 × $1.20 -

×

Dynabrade 78006 1/2" W x 12" L Coarse Non-Woven DynaBrite Belts, 10/pack

10 × $4.69

Dynabrade 78006 1/2" W x 12" L Coarse Non-Woven DynaBrite Belts, 10/pack

10 × $4.69 -

×

Dynabrade 22070 Downdraft Table Accessory Pack (Air Manifold, FRL and On/Off Air Valve)

1 × $709.91

Dynabrade 22070 Downdraft Table Accessory Pack (Air Manifold, FRL and On/Off Air Valve)

1 × $709.91 -

×

Dynabrade 94990 1/4" Female Composite-Style Coupler with 1/4" Male Plug Assembly

1 × $40.31

Dynabrade 94990 1/4" Female Composite-Style Coupler with 1/4" Male Plug Assembly

1 × $40.31 -

×

Norton 66254497067 - 2" X 1/4" 100 - 150 Grit Medium Grade Aluminum Oxide Vortex Rapid Blend Blue TR Non-Woven Abrasive Disc, 25 Each

25 × $4.68

Norton 66254497067 - 2" X 1/4" 100 - 150 Grit Medium Grade Aluminum Oxide Vortex Rapid Blend Blue TR Non-Woven Abrasive Disc, 25 Each

25 × $4.68 -

×

Norton 66261127733 - 2" X 50 Yard 60 Grit Metalite™ Aluminum Oxide Cloth Roll, 1 Each

1 × $72.43

Norton 66261127733 - 2" X 50 Yard 60 Grit Metalite™ Aluminum Oxide Cloth Roll, 1 Each

1 × $72.43 -

×

3M 28764, Cubitron II Cut and Grind Wheel, Type 27 Quick Change, 6 in x 1/8 in x 5/8"-11, 7100019069, 20 per case

20 × $14.80

3M 28764, Cubitron II Cut and Grind Wheel, Type 27 Quick Change, 6 in x 1/8 in x 5/8"-11, 7100019069, 20 per case

20 × $14.80 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 54110, Scotch-Brite Roloc AL Surface Conditioning Disc TR, 1-1/2 in x NH A VFN, 7100075534, 200 per case

$0.97

Discontinued, 3M Suggested Replacement-

| 7100264166 |

The Scotch-Brite Roloc AL Surface Conditioning Disc cleans, finishes, blends and deburrs a variety of substrates, including ferrous and non-ferrous metals. It strikes the perfect balance between strength and softness. Use this disc to rid your workpiece of contaminants without severely altering part geometry.