-

×

Insize LDM-065, LASER SCAN MICROMETER, 0.5-65mm, 6940561942088

2 × $14,881.92

Insize LDM-065, LASER SCAN MICROMETER, 0.5-65mm, 6940561942088

2 × $14,881.92 -

×

Insize ISY-700-90019, STAND, 6940561980677

1 × $11.65

Insize ISY-700-90019, STAND, 6940561980677

1 × $11.65 -

×

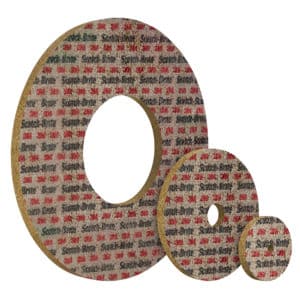

3M 65082, Scotch Brite Roloc Deburr & Finish PRO Unitized Wheel, DP-UR, 6C Medium+, TR, 2 in x 1/4 in x NH, 7100081367

60 × $7.14

3M 65082, Scotch Brite Roloc Deburr & Finish PRO Unitized Wheel, DP-UR, 6C Medium+, TR, 2 in x 1/4 in x NH, 7100081367

60 × $7.14 -

×

3M 05182, Scotch-Brite Cut and Polish Wheel, CP-WL, 5A Fine, 6 in x 1/2 in x 1 in, 7100050403,Box of 4

1 × $94.50

3M 05182, Scotch-Brite Cut and Polish Wheel, CP-WL, 5A Fine, 6 in x 1/2 in x 1 in, 7100050403,Box of 4

1 × $94.50 -

×

Insize QMS-A110-U, QUICK MEASUREMENT SYSTEM, 6940561967623

2 × $21,129.71

Insize QMS-A110-U, QUICK MEASUREMENT SYSTEM, 6940561967623

2 × $21,129.71 -

×

Insize VSP-201R, ROTATING LENS CABLE, cable length 1200", 6940561941326

1 × $11,553.26

Insize VSP-201R, ROTATING LENS CABLE, cable length 1200", 6940561941326

1 × $11,553.26 -

×

Insize PHT-C751-P, PENCIL(17PCS: 6B-9H), 6974029779879

1 × $200.88

Insize PHT-C751-P, PENCIL(17PCS: 6B-9H), 6974029779879

1 × $200.88 -

×

Insize VSP-201W, WIDE-ANGLE LENS CABLE, cable length 1200", 6940561941333

1 × $9,460.96

Insize VSP-201W, WIDE-ANGLE LENS CABLE, cable length 1200", 6940561941333

1 × $9,460.96 -

×

Insize TLP-300H, TOOL PRESETTER (BASIC TYPE), 6928640376443

1 × $11,230.10

Insize TLP-300H, TOOL PRESETTER (BASIC TYPE), 6928640376443

1 × $11,230.10 -

×

Insize MLP-CM60-U, CUTTING MACHINE, 60mm,

1 × $8,571.05

Insize MLP-CM60-U, CUTTING MACHINE, 60mm,

1 × $8,571.05 -

×

Insize MLP-MP43-U, MOUNTING PRESSES (ADVANCED TYPE), 6940561981735

2 × $16,100.81

Insize MLP-MP43-U, MOUNTING PRESSES (ADVANCED TYPE), 6940561981735

2 × $16,100.81 -

×

3M 19674, Scotch-Seal Industrial Sealant 800, Reddish Brown, 5 oz Tube, 7000000792, 36/Case

36 × $23.31

3M 19674, Scotch-Seal Industrial Sealant 800, Reddish Brown, 5 oz Tube, 7000000792, 36/Case

36 × $23.31 -

×

Insize ISY-700-90018, STAND WITH FINE ADJUSTMENT, 6940561980776

2 × $28.53

Insize ISY-700-90018, STAND WITH FINE ADJUSTMENT, 6940561980776

2 × $28.53 -

×

Insize ISY-700-90017, STAND FOR SLICE PARTS, 6940561980769

3 × $18.15

Insize ISY-700-90017, STAND FOR SLICE PARTS, 6940561980769

3 × $18.15 -

×

Insize TLP-P340, TOOL PRESETTER (projection type), 6940561943719

2 × $20,035.03

Insize TLP-P340, TOOL PRESETTER (projection type), 6940561943719

2 × $20,035.03 -

×

Insize QMS-A200-U, QUICK MEASUREMENT SYSTEM, 6974029775109

2 × $36,035.89

Insize QMS-A200-U, QUICK MEASUREMENT SYSTEM, 6974029775109

2 × $36,035.89 -

×

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95 -

×

Insize QMS-A450-U, LARGE SIZE QUICK MEASUREMENT SYSTEMS,

1 × $91,535.21

Insize QMS-A450-U, LARGE SIZE QUICK MEASUREMENT SYSTEMS,

1 × $91,535.21 -

×

Insize THT-A103T-U, TEMPERATURE AND HUMIDITY TESTER, 19.69_29.53_23.62", 6974029771484

2 × $25,378.36

Insize THT-A103T-U, TEMPERATURE AND HUMIDITY TESTER, 19.69_29.53_23.62", 6974029771484

2 × $25,378.36 -

×

3M 80510, Roloc Disc 777F, P120 YF-weight, TR, 1 in, Die R100N, 7000045622

500 × $0.62

3M 80510, Roloc Disc 777F, P120 YF-weight, TR, 1 in, Die R100N, 7000045622

500 × $0.62 -

×

Insize 0210-G260, INFRARED THERMOMETER (BASIC TYPE), -22 ?F~500?F/-30?C~260?C, 6974029773310

1 × $66.86

Insize 0210-G260, INFRARED THERMOMETER (BASIC TYPE), -22 ?F~500?F/-30?C~260?C, 6974029773310

1 × $66.86 -

×

Dynabrade 01185 Vane Set (4pk)

1 × $24.78

Dynabrade 01185 Vane Set (4pk)

1 × $24.78 -

×

Insize QMY-AP32-U, ROTATIONAL ABRASION TESTER, 6940561937848

2 × $7,073.64

Insize QMY-AP32-U, ROTATIONAL ABRASION TESTER, 6940561937848

2 × $7,073.64 -

×

Insize ISY-700-90014, STAND, 6940561980738

1 × $22.81

Insize ISY-700-90014, STAND, 6940561980738

1 × $22.81 -

×

Insize THT-A101T-U, TEMPERATURE AND HUMIDITY TESTER, 19.69_23.62_19.69", 6974029771446

1 × $22,660.11

Insize THT-A101T-U, TEMPERATURE AND HUMIDITY TESTER, 19.69_23.62_19.69", 6974029771446

1 × $22,660.11 -

×

Insize PHT-C751-S, 400 GRADE ABRASIVE PAPER, 6974029779886

1 × $15.92

Insize PHT-C751-S, 400 GRADE ABRASIVE PAPER, 6974029779886

1 × $15.92 -

×

Insize VSP-201H, RIGID CABLE, cable length 9.84", 6940561941319

1 × $2,854.11

Insize VSP-201H, RIGID CABLE, cable length 9.84", 6940561941319

1 × $2,854.11 -

×

3M 76751, Roloc Disc 777F, 60 YF-weight, TS, 3 in, Die RS300V, 7010363900

200 × $1.43

3M 76751, Roloc Disc 777F, 60 YF-weight, TS, 3 in, Die RS300V, 7010363900

200 × $1.43 -

×

Insize VSP-201D, FOUR DIRECTION CABLE(FRONT VIEW), cable length 120", 6940561941302

1 × $3,496.55

Insize VSP-201D, FOUR DIRECTION CABLE(FRONT VIEW), cable length 120", 6940561941302

1 × $3,496.55 -

×

Insize MLP-MP53-U, MOUNTING PRESSES (ADVANCED TYPE), 6940561981742

2 × $29,668.74

Insize MLP-MP53-U, MOUNTING PRESSES (ADVANCED TYPE), 6940561981742

2 × $29,668.74 -

×

Insize 0120-IM24, INDUCTIVE MOISTURE METER, 0~100%, 6974029776588

1 × $207.68

Insize 0120-IM24, INDUCTIVE MOISTURE METER, 0~100%, 6974029776588

1 × $207.68 -

×

Insize ISY-700-90028, ACRYLIC SLIDING SUPPORT PLATE, 6940561980851

1 × $22.81

Insize ISY-700-90028, ACRYLIC SLIDING SUPPORT PLATE, 6940561980851

1 × $22.81 -

×

Insize UTM-E50, DIGITAL UNIVERSAL TESTING MACHINE, 50kN, 6940561904673

1 × $36,507.53

Insize UTM-E50, DIGITAL UNIVERSAL TESTING MACHINE, 50kN, 6940561904673

1 × $36,507.53 -

×

Insize 7315-7, WIRELESS DATA TRANSFER SYSTEM, MULTICHANNEL RECEIVER (Type-C port), 6940561938784

1 × $316.26

Insize 7315-7, WIRELESS DATA TRANSFER SYSTEM, MULTICHANNEL RECEIVER (Type-C port), 6940561938784

1 × $316.26 -

×

Insize 1138-200, DIGITAL CALIPER WITH LONG UPPER JAWS, 0-8"/0-200mm, 6928640392344

1 × $454.90

Insize 1138-200, DIGITAL CALIPER WITH LONG UPPER JAWS, 0-8"/0-200mm, 6928640392344

1 × $454.90 -

×

Insize 2187-6, ADJUSTABLE SNAP GAGE, 0-.24", 6928640314360

1 × $125.64

Insize 2187-6, ADJUSTABLE SNAP GAGE, 0-.24", 6928640314360

1 × $125.64 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

Dynabrade 25234 Vane Set (4pk)

1 × $26.39

Dynabrade 25234 Vane Set (4pk)

1 × $26.39 -

×

Insize VSP-201, MULTIPURPOSE VIDEOSCOPE,MAIN UNIT, 6940561941296

1 × $5,254.04

Insize VSP-201, MULTIPURPOSE VIDEOSCOPE,MAIN UNIT, 6940561941296

1 × $5,254.04 -

×

Insize QMS-CALIBRATION, CALIBRATION PLATE for QMS,

2 × $1,955.47

Insize QMS-CALIBRATION, CALIBRATION PLATE for QMS,

2 × $1,955.47 -

×

Insize MLP-GP280-U, GRINDER AND POLISHER, 6940561981704

1 × $8,444.90

Insize MLP-GP280-U, GRINDER AND POLISHER, 6940561981704

1 × $8,444.90 -

×

Insize ISY-700-90022, L-SHAPED POSITIONING PLATE, 6940561980806

1 × $29.40

Insize ISY-700-90022, L-SHAPED POSITIONING PLATE, 6940561980806

1 × $29.40 -

×

3M 65086, Scotch-Brite Diamond Wheel, 6" x 1" x 1" 645DC, 7010329878

1 × $945.02

3M 65086, Scotch-Brite Diamond Wheel, 6" x 1" x 1" 645DC, 7010329878

1 × $945.02 -

×

Insize ISY-700-90023, SLIDING SUPPORT PLATE, 6940561980813

1 × $17.86

Insize ISY-700-90023, SLIDING SUPPORT PLATE, 6940561980813

1 × $17.86 -

×

Insize ISY-700-90024, SQUARE SUPPORT, 6940561980820

2 × $34.06

Insize ISY-700-90024, SQUARE SUPPORT, 6940561980820

2 × $34.06 -

×

ACS CX1250 Diamond Belts, 1/2" X 24" 200u

12 × $8.20

ACS CX1250 Diamond Belts, 1/2" X 24" 200u

12 × $8.20 -

×

Insize MLP-GP314-U, GRINDER AND POLISHER(BASIC TYPE), 7.99" DIA, 6974029771415

2 × $5,218.13

Insize MLP-GP314-U, GRINDER AND POLISHER(BASIC TYPE), 7.99" DIA, 6974029771415

2 × $5,218.13 -

×

Insize ISY-100-1201, CLIP, 2PCS, 6940561936209

1 × $67.25

Insize ISY-100-1201, CLIP, 2PCS, 6940561936209

1 × $67.25 -

×

Insize MLP-CM86, CUTTING MACHINE (BASIC TYPE), 80mm, 6974029771408

1 × $5,806.23

Insize MLP-CM86, CUTTING MACHINE (BASIC TYPE), 80mm, 6974029771408

1 × $5,806.23 -

×

Standard Abrasives 850374, GP Wheel, 6 in x 1 in x 1 in 9S FIN, 7100025515

5 × $49.57

Standard Abrasives 850374, GP Wheel, 6 in x 1 in x 1 in 9S FIN, 7100025515

5 × $49.57 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 50461, Stikit Cloth Disc 202DZ, P120 J-weight, 6 in x NH, Die 600Z, 7000119037

This item has been Discontinued. Please see 3M suggested replacement item 77100284563.

3M Stikit Cloth Disc 202DZ offers the convenience of a Stikit attachment combined with the durability of aluminum oxide on a flexible cloth backing, along with static resistant coating and other load resistant features for applications where dust is a concern. Our 3M Stikit pressure sensitive adhesive provides ease of attachment to a random orbital sander and a clean removal.