-

×

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

3 × $502.78

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

3 × $502.78 -

×

ACS CX1250 Diamond Belts, 1/2" X 24" 45u

12 × $7.60

ACS CX1250 Diamond Belts, 1/2" X 24" 45u

12 × $7.60 -

×

Dynabrade 51865 1.0 hp Trim Router (Complete), 20,000 RPM, 1/4 Collet

1 × $880.00

Dynabrade 51865 1.0 hp Trim Router (Complete), 20,000 RPM, 1/4 Collet

1 × $880.00 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98 -

×

Dynabrade 90872 2" Dia. Coarse NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89

Dynabrade 90872 2" Dia. Coarse NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89 -

×

Air Turbine Tools 310RSV - 1/4" Router Hand Tool Series with Brake, 40,000RPM, 33444

1 × $975.00

Air Turbine Tools 310RSV - 1/4" Router Hand Tool Series with Brake, 40,000RPM, 33444

1 × $975.00 -

×

3M 33501, Sanding Respirator, 03201, 7000120129, 2 per pack

12 × $6.12

3M 33501, Sanding Respirator, 03201, 7000120129, 2 per pack

12 × $6.12 -

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

2 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

2 × $129.94 -

×

3M 87147, PSA Cloth Disc 777F, 5 x NH, 36 YF-weightt, 7010308524

250 × $3.18

3M 87147, PSA Cloth Disc 777F, 5 x NH, 36 YF-weightt, 7010308524

250 × $3.18 -

×

3M 62602, Scotch-Weld Threadlocker TL22, Purple, 50 mL Bottle, 7100039159, 10/case

10 × $42.72

3M 62602, Scotch-Weld Threadlocker TL22, Purple, 50 mL Bottle, 7100039159, 10/case

10 × $42.72 -

×

3M 08019, Marine Grade Silicone Sealant, Clear, 3 oz Tube, 7000120480, 6/Case

6 × $15.76

3M 08019, Marine Grade Silicone Sealant, Clear, 3 oz Tube, 7000120480, 6/Case

6 × $15.76 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

60 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

60 × $7.30 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 74u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 74u

12 × $7.60 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

3M 08023, Adhesive Sealant 740 UV, White, 600 mL Sausage Pack, 7000000933, 12/Case

12 × $19.37

3M 08023, Adhesive Sealant 740 UV, White, 600 mL Sausage Pack, 7000000933, 12/Case

12 × $19.37 -

×

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

2 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

2 × $192.76 -

×

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

3M 19768, Utility Cloth Sheet 314D, 9 in x 11 in P180 J-weight, 7000000356

250 × $1.37

3M 19768, Utility Cloth Sheet 314D, 9 in x 11 in P180 J-weight, 7000000356

250 × $1.37 -

×

3M 26129, PPS Series 2.0 Adapter, Type S34, 3/8 Female, 18 Thread NPS, 7100135938

4 × $38.43

3M 26129, PPS Series 2.0 Adapter, Type S34, 3/8 Female, 18 Thread NPS, 7100135938

4 × $38.43 -

×

3M 26105, PPS Series 2.0 Adapter, Type S21, 14 mm Female, 1.0 mm

Thread, 7100135829

1 × $25.96

3M 26105, PPS Series 2.0 Adapter, Type S21, 14 mm Female, 1.0 mm

Thread, 7100135829

1 × $25.96 -

×

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00 -

×

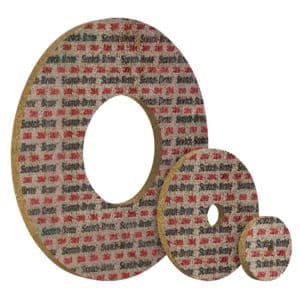

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70

Binks 183G-523, 5 Gallon Paint/Pressure Tank, Galvanized, Dual Regulation, Gear Reduced Agitation

$3,065.00

In Stock.

Includes 20:1 gear reduced agitator. Galvanized lid and tank shell. Binks 183G- ASME Code Tanks give you application flexibility for most solvent borne applications. Disposable liners available for ease of cleaning. ASME Code Galvanized Carbon Steel Tanks.

Binks A.S.M.E. code tanks meet OSHA regulations when using flammable and combustible materials

– Constructed from heavy gauge steel with forged steel clamps

– Higher pressure rating for heavier materials

– Range offers complete material handling suitability for solvent and waterborne coatings

– Inner liners reduce cleaning time and save coating material

Binks pressure feed containers are used to allow the coating material to be prepared, thinned and conditioned, constantly agitated (if required) and then supplied in bulk to consistently maintain the correct spraying viscosity and pressure.

The Binks range is equipped with easy to operate air regulators (to set the desired fluid outlet pressure), safety pressure relief valves and manual, rotary or oscillating agitation types are available to provide the best quality agitation.

Binks Pressure Feed Containers are constructed from the highest-grade materials and fully comply with global pressure regulations including PED, ATEX and ASME.

Galvanized Pressure Tanks

Galvanized steel tanks are primarily used with non-corrosive materials. Constructed with a heavy pressed steel lid and forged steel clamps, galvanized tanks are equipped with top outlet and bottom outlet plug, which can be adapted for bottom outlet. The bottom outlet is recommended for heavy, viscous materials such as emulsified asphalts, cutback asphalts, rubber compounds, etc.

Stainless Steel Pressure Tanks

Stainless Steel Pressure Tanks are suitable for virtually all fluids and solvents. They are ASME certified and permanently labeled for 110 PSIG maximum working pressure. Tanks and lids are constructed of heavy gauge 304 stainless steel and are also electro polished. All models are equipped with top outlet and bottom outlet plug, which can be adapted for bottom outlet. Additionally, these tanks are fitted with 100% stainless steel non-corrosive and non-corroding wetted parts.

Related products

Adhesives & Sealants

3M 41531, Scotch-Weld Epoxy Adhesive 420, Black, Part B, 5 Gallon Drum (Pail), 7000000827

$583.75