-

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78 -

×

3M 19677, Scotch-Seal Industrial Sealant 800, Reddish Brown, 1 Gallon Drum, 7000000793, 4/Case

4 × $251.59

3M 19677, Scotch-Seal Industrial Sealant 800, Reddish Brown, 1 Gallon Drum, 7000000793, 4/Case

4 × $251.59 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

3M 33501, Sanding Respirator, 03201, 7000120129, 2 per pack

12 × $6.12

3M 33501, Sanding Respirator, 03201, 7000120129, 2 per pack

12 × $6.12 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06 -

×

ACS Diamond Cloth Belt, CX1250 3" X 30" 45U

2 × $57.10

ACS Diamond Cloth Belt, CX1250 3" X 30" 45U

2 × $57.10 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

30 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

30 × $7.30 -

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

2 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

2 × $129.94 -

×

3M 84768, Scotch Box Sealing Tape Hand Dispenser H190, 2 in, 12/Case, 7000056553

12 × $17.04

3M 84768, Scotch Box Sealing Tape Hand Dispenser H190, 2 in, 12/Case, 7000056553

12 × $17.04 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00 -

×

3M 06953, Scotch Filament Tape Hand Dispenser H12, 1 in, 6/Case, 7000005393

6 × $36.76

3M 06953, Scotch Filament Tape Hand Dispenser H12, 1 in, 6/Case, 7000005393

6 × $36.76 -

×

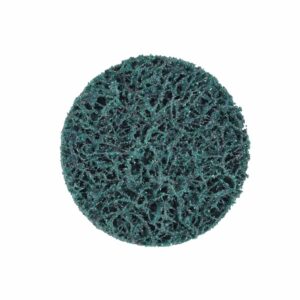

3M 14593, Scotch-Brite Cut and Polish Disc, 3" x 1-1/4" x 1/4" A Medium, D5, 7000045941, Box of 10

10 × $16.71

3M 14593, Scotch-Brite Cut and Polish Disc, 3" x 1-1/4" x 1/4" A Medium, D5, 7000045941, Box of 10

10 × $16.71 -

×

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

200 × $1.74

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

200 × $1.74 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73 -

×

3M 54358, Particulate Respirator 8247, R95, with Nuisance Level, Organic Vapor Relief, 7000002060, 120 EA/Case

1 × $494.49

3M 54358, Particulate Respirator 8247, R95, with Nuisance Level, Organic Vapor Relief, 7000002060, 120 EA/Case

1 × $494.49 -

×

Standard Abrasives 827620, Buff and Blend HP Power Pad, 6 in x 9 in, A VFN, 7010310293, 50 ea/Case

1 × $190.45

Standard Abrasives 827620, Buff and Blend HP Power Pad, 6 in x 9 in, A VFN, 7010310293, 50 ea/Case

1 × $190.45 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58 -

×

3M 80751, Scotch Super Glue Liquid AD114, 4-Pack of Single-Use Tubes, .017 oz, 7000047643

36 × $2.16

3M 80751, Scotch Super Glue Liquid AD114, 4-Pack of Single-Use Tubes, .017 oz, 7000047643

36 × $2.16 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M 40544, VHB Tape LSE-060WF, White, 1/2 in x 36 yd, 0.6 mm, 18 rolls per case, 7100218845

$36.22

Factory Stock, 7-10 Day Leadtime

Dream, Design, Deliver with our 3M VHB Tape 5907. It is a black, 0.008 in (0.20 mm), modified acrylic adhesive with a very conformable, foam core. This tape can replace mechanical fasteners or liquid adhesives and is designed specifically for applications with thin bond lines. The fast and easy to use permanent bonding method provides high strength and long-term durability.