-

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

3M 04029, Scotch-Brite Hand Pad 7447, HP-HP, A/O Very Fine, Maroon, 6 in x 9 in, 7000000728, 60/Case

1 × $82.43

3M 04029, Scotch-Brite Hand Pad 7447, HP-HP, A/O Very Fine, Maroon, 6 in x 9 in, 7000000728, 60/Case

1 × $82.43 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

Dynabrade 92118 1/4" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.15

Dynabrade 92118 1/4" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.15 -

×

Dynabrade 95676 1/4" Female Coupler with 1/4" Male Plug Assembly

1 × $31.48

Dynabrade 95676 1/4" Female Coupler with 1/4" Male Plug Assembly

1 × $31.48 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

2 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

2 × $453.00 -

×

3M 05182, Scotch-Brite Cut and Polish Wheel, CP-WL, 5A Fine, 6 in x 1/2 in x 1 in, 7100050403,Box of 4

1 × $94.50

3M 05182, Scotch-Brite Cut and Polish Wheel, CP-WL, 5A Fine, 6 in x 1/2 in x 1 in, 7100050403,Box of 4

1 × $94.50 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00 -

×

Dynabrade 51622 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 35,000 RPM, 3mm Collet

1 × $603.00

Dynabrade 51622 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 35,000 RPM, 3mm Collet

1 × $603.00 -

×

3M 05530, Stikit Soft Hand Pad, 2-3/4 in x 5-1/2 in x 3/8 in, 7000028351

50 × $5.53

3M 05530, Stikit Soft Hand Pad, 2-3/4 in x 5-1/2 in x 3/8 in, 7000028351

50 × $5.53 -

×

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37 -

×

Air Turbine Tools 310RDM - 6mm Router Hand Tool Series, 30,000RPM, 33433

1 × $950.00

Air Turbine Tools 310RDM - 6mm Router Hand Tool Series, 30,000RPM, 33433

1 × $950.00 -

×

Dynabrade 98269 1/2" Female Coupler

1 × $56.65

Dynabrade 98269 1/2" Female Coupler

1 × $56.65 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00 -

×

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52 -

×

3M 35833, Hookit Dust Extraction Flexible Radius Sanding Block Kit, 7100259118

10 × $153.37

3M 35833, Hookit Dust Extraction Flexible Radius Sanding Block Kit, 7100259118

10 × $153.37 -

×

Standard Abrasives 725004, Buff and Blend Cross Buff GP, A/O Coarse, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7000047136

50 × $6.37

Standard Abrasives 725004, Buff and Blend Cross Buff GP, A/O Coarse, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7000047136

50 × $6.37 -

×

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00 -

×

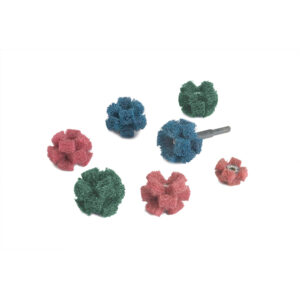

3M 13800, Scotch-Brite Star, 1-1/2 in A VFN LS, 7000120969

100 × $3.24

3M 13800, Scotch-Brite Star, 1-1/2 in A VFN LS, 7000120969

100 × $3.24 -

×

Dynabrade 94991 1/4" Female Composite-Style Coupler with 1/4" Female Plug Assembly

1 × $46.24

Dynabrade 94991 1/4" Female Composite-Style Coupler with 1/4" Female Plug Assembly

1 × $46.24 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

25 × $4.57

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

25 × $4.57 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M 40544, VHB Tape LSE-060WF, White, 1/2 in x 36 yd, 0.6 mm, 18 rolls per case, 7100218845

$36.22

Factory Stock, 7-10 Day Leadtime

Dream, Design, Deliver with our 3M VHB Tape 5907. It is a black, 0.008 in (0.20 mm), modified acrylic adhesive with a very conformable, foam core. This tape can replace mechanical fasteners or liquid adhesives and is designed specifically for applications with thin bond lines. The fast and easy to use permanent bonding method provides high strength and long-term durability.