-

×

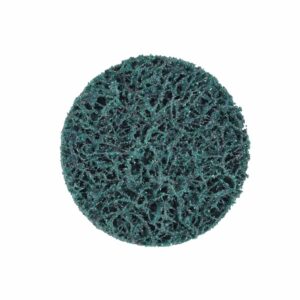

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21 -

×

3M 47195, Polyurethane Construction Sealant 525, Gray, 600 mL Sausage Pack, 7100198003, 12/Case

12 × $12.12

3M 47195, Polyurethane Construction Sealant 525, Gray, 600 mL Sausage Pack, 7100198003, 12/Case

12 × $12.12 -

×

3M 25496, Scotch-Weld Epoxy Adhesive 2214 Non-Metallic Filled, Cream, 6 fl oz Cartridge, 7000121273, 4/case

4 × $94.36

3M 25496, Scotch-Weld Epoxy Adhesive 2214 Non-Metallic Filled, Cream, 6 fl oz Cartridge, 7000121273, 4/case

4 × $94.36 -

×

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40 -

×

Dynabrade 51705 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 3/32" Collet

1 × $558.00

Dynabrade 51705 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 3/32" Collet

1 × $558.00 -

×

Dynabrade 31920 - 1-1/4" (32 mm) Static Conductive Hose, Black

1 × $15.81

Dynabrade 31920 - 1-1/4" (32 mm) Static Conductive Hose, Black

1 × $15.81 -

×

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33 -

×

3M 05508, Marine Adhesive Sealant 4000 UV, White, 600 mL Sausage Pack, 7010330455, 12/Case

12 × $22.18

3M 05508, Marine Adhesive Sealant 4000 UV, White, 600 mL Sausage Pack, 7010330455, 12/Case

12 × $22.18 -

×

Dynabrade 51622 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 35,000 RPM, 3mm Collet

1 × $603.00

Dynabrade 51622 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 35,000 RPM, 3mm Collet

1 × $603.00 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93 -

×

Dynabrade Nitro Series DGS31 .3hp, 25,000 RPM, Straight-Line Die Grinder, 1/4 Collet

1 × $120.00

Dynabrade Nitro Series DGS31 .3hp, 25,000 RPM, Straight-Line Die Grinder, 1/4 Collet

1 × $120.00 -

×

Dynabrade 51333 .7 hp Router, 4" Base, Central Vacuum, 20,000 RPM, 1/4 Collet

1 × $1,031.00

Dynabrade 51333 .7 hp Router, 4" Base, Central Vacuum, 20,000 RPM, 1/4 Collet

1 × $1,031.00 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47 -

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33 -

×

Norton 66261014897 2" x 1/4" Bear-Tex NEX Rapid Blend AO Medium Grit TR (Type III) Non-Woven Wheel, 60 Each

60 × $4.78

Norton 66261014897 2" x 1/4" Bear-Tex NEX Rapid Blend AO Medium Grit TR (Type III) Non-Woven Wheel, 60 Each

60 × $4.78 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76

3M 40544, VHB Tape LSE-060WF, White, 1/2 in x 36 yd, 0.6 mm, 18 rolls per case, 7100218845

$36.22

Factory Stock, 7-10 Day Leadtime

Dream, Design, Deliver with our 3M VHB Tape 5907. It is a black, 0.008 in (0.20 mm), modified acrylic adhesive with a very conformable, foam core. This tape can replace mechanical fasteners or liquid adhesives and is designed specifically for applications with thin bond lines. The fast and easy to use permanent bonding method provides high strength and long-term durability.