-

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67 -

×

3M 97419, Aluminum Foil Tape 3380, Silver, 48 mm x 45 m, 3.25 mil, 7000049613

24 × $16.94

3M 97419, Aluminum Foil Tape 3380, Silver, 48 mm x 45 m, 3.25 mil, 7000049613

24 × $16.94 -

×

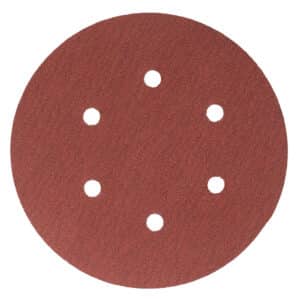

3M 45722, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 6 in x NH, D/F 6HL, Die 600HZ, 7100113871

200 × $2.53

3M 45722, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 6 in x NH, D/F 6HL, Die 600HZ, 7100113871

200 × $2.53 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 31467, Double Coated Tape 9737R, Red, 36 mm x 55 m, 3.5 mil, 32 rolls per case, 7000049264

$15.71

Factory Stock, 7-10 Day Leadtime

3M Double Coated Tape 9737 Clear is a double-sided tape mounted on a thin polyester carrier with a pressure sensitive acrylic adhesive that offers a balance of high initial adhesion and good holding power. It is mounted on 55 lb. densified kraft paper liner for easy release and manipulation during application.