-

×

Standard Abrasives 840031, Quick Change Surface Conditioning FE Disc, A/O Coarse, TSM, Brown, 3/4 in, QS75KM, 7000046845, 50/case

50 × $0.84

Standard Abrasives 840031, Quick Change Surface Conditioning FE Disc, A/O Coarse, TSM, Brown, 3/4 in, QS75KM, 7000046845, 50/case

50 × $0.84 -

×

Dynabrade 51740 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet, with Mount Stem

1 × $512.00

Dynabrade 51740 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet, with Mount Stem

1 × $512.00 -

×

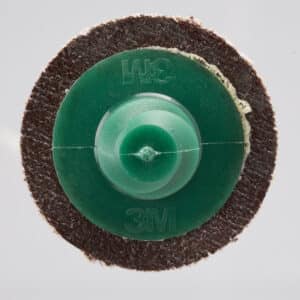

3M 76623, Roloc Disc 777F, 50 YF-weight, TR, 1 in, Die R100N, 7000045619

500 × $0.65

3M 76623, Roloc Disc 777F, 50 YF-weight, TR, 1 in, Die R100N, 7000045619

500 × $0.65 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58 -

×

Dynabrade 51706 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

2 × $558.00

Dynabrade 51706 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

2 × $558.00 -

×

Dynabrade 51756 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

1 × $603.00

Dynabrade 51756 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

1 × $603.00 -

×

3M 62610, Scotch-Weld Threadlocker TL62, Red, 50 mL Bottle, 7100039196, 10/case

10 × $36.70

3M 62610, Scotch-Weld Threadlocker TL62, Red, 50 mL Bottle, 7100039196, 10/case

10 × $36.70 -

×

3M 85335, Aluminum Foil Tape 425, Silver, 6 in x 60 yd, 4.6 mil, 7100053593

2 × $227.76

3M 85335, Aluminum Foil Tape 425, Silver, 6 in x 60 yd, 4.6 mil, 7100053593

2 × $227.76 -

×

3M 05206, Marine Adhesive Sealant 5200, White, 1 oz Tube, 7010325697, 12/Case

12 × $9.29

3M 05206, Marine Adhesive Sealant 5200, White, 1 oz Tube, 7010325697, 12/Case

12 × $9.29 -

×

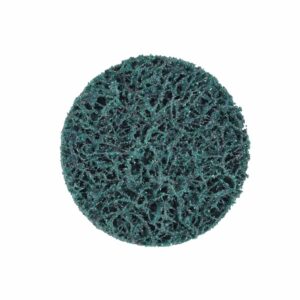

3M 15913, Scotch-Brite Roloc Disc High Strength, TR, 2 in X NH A Medium, 7000000710

200 × $1.72

3M 15913, Scotch-Brite Roloc Disc High Strength, TR, 2 in X NH A Medium, 7000000710

200 × $1.72 -

×

3M 36879, Self-Stick Liquid Protection Fabric, Blue, 28 in x 300 ft, 7100169496

1 × $623.42

3M 36879, Self-Stick Liquid Protection Fabric, Blue, 28 in x 300 ft, 7100169496

1 × $623.42 -

×

3M 57173, Temflex Cotton Friction Tape 1755, 3/4 in x 60 ft, Black, 7000058870

20 × $7.66

3M 57173, Temflex Cotton Friction Tape 1755, 3/4 in x 60 ft, Black, 7000058870

20 × $7.66 -

×

ACS CX1250 Diamond Belts, 1/2" X 24" 45u

12 × $7.60

ACS CX1250 Diamond Belts, 1/2" X 24" 45u

12 × $7.60 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 20u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 20u

12 × $7.60 -

×

3M 94008, Scotch Super Glue Gel in Precision Applicator, AD125, .14 oz (4 g), 7100035277

36 × $2.42

3M 94008, Scotch Super Glue Gel in Precision Applicator, AD125, .14 oz (4 g), 7100035277

36 × $2.42 -

×

3M 69436, Cloth Belt 577F, 120 YF-weight, 1/2 in x 24 in, Fabri-lok, Single-flex, 7000119456, 200 per case

200 × $1.57

3M 69436, Cloth Belt 577F, 120 YF-weight, 1/2 in x 24 in, Fabri-lok, Single-flex, 7000119456, 200 per case

200 × $1.57 -

×

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

36 × $18.24

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

36 × $18.24 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 250u

12 × $8.20

ACS CX1250 Diamond Belt, 1/2" X 24" 250u

12 × $8.20 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14 -

×

Dynabrade 55500 .1hp Pencil Grinder, Twin Turbine, 100,000 RPM, Nickel-Plated Aluminum Housing, 1/8" Collet

1 × $557.00

Dynabrade 55500 .1hp Pencil Grinder, Twin Turbine, 100,000 RPM, Nickel-Plated Aluminum Housing, 1/8" Collet

1 × $557.00 -

×

3M 62611, Scotch-Weld Threadlocker TL62, Red, 250 mL Bottle, 7100039195, 2/case

2 × $100.85

3M 62611, Scotch-Weld Threadlocker TL62, Red, 250 mL Bottle, 7100039195, 2/case

2 × $100.85 -

×

3M 05536, Cubitron II Cloth Belt 981F, 4 x 132 in, 60+, YF-weight, Film-lok, 7100163076, 25 per case

25 × $21.55

3M 05536, Cubitron II Cloth Belt 981F, 4 x 132 in, 60+, YF-weight, Film-lok, 7100163076, 25 per case

25 × $21.55 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

Standard Abrasives 32938, PSA A/O Disc, 710322, 3/4 in x NH, 120, 7000121791

100 × $0.10

Standard Abrasives 32938, PSA A/O Disc, 710322, 3/4 in x NH, 120, 7000121791

100 × $0.10 -

×

Dynabrade 51705 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 3/32" Collet

1 × $558.00

Dynabrade 51705 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 3/32" Collet

1 × $558.00 -

×

3M 21463, Marine Adhesive Sealant 5200, White, 5 Gallon Drum (Pail), 7010325698

1 × $1,029.08

3M 21463, Marine Adhesive Sealant 5200, White, 5 Gallon Drum (Pail), 7010325698

1 × $1,029.08 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M 24965, 3M PTFE Film Tape 5498, Beige, 2 in x 36 yd, 4.2 mil, 24 rolls per case, 7000048642

$199.95

Factory Stock, 7-10 Day Leadtime

3M PTFE Film Tape 5498 uses an extruded polytetrafluoroethylene (PTFE) film backing. This tape offers an extremely low coefficient of friction which, in combination with a pressure sensitive rubber adhesive, creates a smooth, non-stick surface over a variety of substrates to assist in mold release applications where a non-silicone tape is required.