-

×

Dynabrade 51702 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 3/32" Collet

1 × $558.00

Dynabrade 51702 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 3/32" Collet

1 × $558.00 -

×

Dynabrade 51811 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/16" Collet

1 × $751.00

Dynabrade 51811 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/16" Collet

1 × $751.00 -

×

3M 57894, 642WY 1/4" X 24", 50000 Mesh Diamond Cloth Belt, 7100230570

15 × $0.00

3M 57894, 642WY 1/4" X 24", 50000 Mesh Diamond Cloth Belt, 7100230570

15 × $0.00 -

×

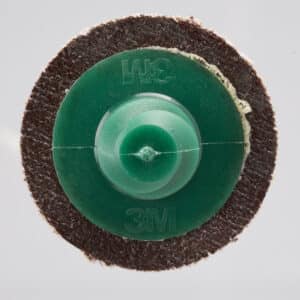

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

1000 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

1000 × $0.75 -

×

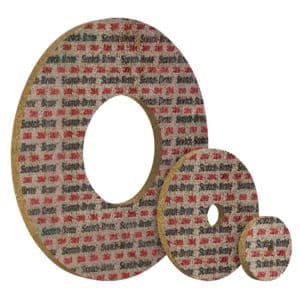

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60 -

×

3M 19772, Utility Cloth Sheet 314D, 9 in x 11 in P80 J-weight, 7000000359

250 × $1.45

3M 19772, Utility Cloth Sheet 314D, 9 in x 11 in P80 J-weight, 7000000359

250 × $1.45 -

×

3M 99297, Scotch-Weld Structural Plastic Adhesive DP8005, Off-White, 490 mLDuo-Pak, 7100090196, 6/case

6 × $317.12

3M 99297, Scotch-Weld Structural Plastic Adhesive DP8005, Off-White, 490 mLDuo-Pak, 7100090196, 6/case

6 × $317.12 -

×

3M 05203, Marine Adhesive Sealant 5200, White, 3 oz Tube, 7000118401, 6/Case

6 × $15.40

3M 05203, Marine Adhesive Sealant 5200, White, 3 oz Tube, 7000118401, 6/Case

6 × $15.40 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58 -

×

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21 -

×

ACS Diamond Cloth Belt, CX1250 3/8" X 24" 75U

16 × $5.80

ACS Diamond Cloth Belt, CX1250 3/8" X 24" 75U

16 × $5.80 -

×

Dynabrade 51750 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $603.00

Dynabrade 51750 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $603.00 -

×

Dynabrade 51740 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet, with Mount Stem

2 × $512.00

Dynabrade 51740 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet, with Mount Stem

2 × $512.00 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00 -

×

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76 -

×

3M 05049, Cloth Belt 384F, 80+ XF-weight, 1 in x 30 in, Fabri-lok, Full-flex, 7100141431, 200 per case

200 × $1.92

3M 05049, Cloth Belt 384F, 80+ XF-weight, 1 in x 30 in, Fabri-lok, Full-flex, 7100141431, 200 per case

200 × $1.92 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

Standard Abrasives 32985, Aluminum Oxide Overlap Disc, 714721, 60 Grit, 2 in x 8-32 x 2 Ply, 7100116380

100 × $1.67

Standard Abrasives 32985, Aluminum Oxide Overlap Disc, 714721, 60 Grit, 2 in x 8-32 x 2 Ply, 7100116380

100 × $1.67 -

×

Dynabrade 51810 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/8" Collet

1 × $751.00

Dynabrade 51810 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/8" Collet

1 × $751.00 -

×

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98 -

×

3M 76630, Roloc Disc 777F, 50 YF-weight, TR, 2 in, Die R200P, 7000045627

200 × $1.18

3M 76630, Roloc Disc 777F, 50 YF-weight, TR, 2 in, Die R200P, 7000045627

200 × $1.18 -

×

Dynabrade 51756 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

1 × $603.00

Dynabrade 51756 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

1 × $603.00 -

×

Norton 66623325038 - 3" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep, TR (Type III) Non-Woven Surface Preparation Disc, 25 Each

25 × $3.41

Norton 66623325038 - 3" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep, TR (Type III) Non-Woven Surface Preparation Disc, 25 Each

25 × $3.41 -

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 24842, 3M PTFE Film Tape 5498, Beige, 1 in x 36 yd, 4.2 mil, 36 rolls per case, 7000048643

$99.98

Factory Stock, 7-10 Day Leadtime

3M PTFE Film Tape 5498 uses an extruded polytetrafluoroethylene (PTFE) film backing. This tape offers an extremely low coefficient of friction which, in combination with a pressure sensitive rubber adhesive, creates a smooth, non-stick surface over a variety of substrates to assist in mold release applications where a non-silicone tape is required.