-

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

Dynabrade 51624 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 35,000 RPM, 3mm Collet

1 × $603.00

Dynabrade 51624 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 35,000 RPM, 3mm Collet

1 × $603.00 -

×

ACS Diamond Cloth Belt, CX1250 1/2" X 18" 125U

12 × $5.70

ACS Diamond Cloth Belt, CX1250 1/2" X 18" 125U

12 × $5.70 -

×

Dynabrade 51740 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet, with Mount Stem

1 × $512.00

Dynabrade 51740 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet, with Mount Stem

1 × $512.00 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

36 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

36 × $9.52 -

×

3M 53034, 663FC, 3/4" X 90", 20u, Diamond Trizact Belt 7100205969

1 × $359.45

3M 53034, 663FC, 3/4" X 90", 20u, Diamond Trizact Belt 7100205969

1 × $359.45 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

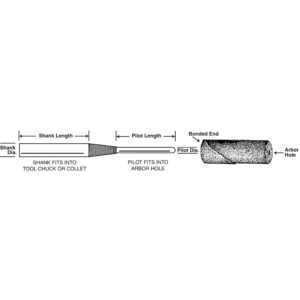

Standard Abrasives 716916, Cartridge RoII Mandrel, 6997818, 1/8 in x 3/4 in x 1/4 in x 6 in CM-XL, 7010368732

5 × $12.14

Standard Abrasives 716916, Cartridge RoII Mandrel, 6997818, 1/8 in x 3/4 in x 1/4 in x 6 in CM-XL, 7010368732

5 × $12.14 -

×

Dynabrade 51632 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $603.00

Dynabrade 51632 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $603.00 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

3M 84158, Microfinishing PSA Film Disc 366L, 30 Mic 3MIL, Type D, 5 in x NH, Die 500X, 7010360217, 500 per case

500 × $0.88

3M 84158, Microfinishing PSA Film Disc 366L, 30 Mic 3MIL, Type D, 5 in x NH, Die 500X, 7010360217, 500 per case

500 × $0.88 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

Dynabrade 51756 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

1 × $603.00

Dynabrade 51756 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

1 × $603.00 -

×

3M 28217, Cubitron II Roloc Disc 984F, 60+ YF-weight, TR, 3 in, Die R300V, 7010326790

200 × $1.78

3M 28217, Cubitron II Roloc Disc 984F, 60+ YF-weight, TR, 3 in, Die R300V, 7010326790

200 × $1.78 -

×

3M 19773, Utility Cloth Sheet 314D, 9 in x 11 in P60 X-weight, 7000000360

50 × $1.75

3M 19773, Utility Cloth Sheet 314D, 9 in x 11 in P60 X-weight, 7000000360

50 × $1.75 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00 -

×

3M 23897, Cloth Belt 777F, 60 YF-weight, 1 in x 18 in, Fabri-lok, Full-flex, 7010307894, 200 per case

200 × $3.47

3M 23897, Cloth Belt 777F, 60 YF-weight, 1 in x 18 in, Fabri-lok, Full-flex, 7010307894, 200 per case

200 × $3.47 -

×

Dynabrade 51731 .1 hp Straight-Line Pencil Grinder, 60,000 RPM, 1/8" Collet

1 × $634.00

Dynabrade 51731 .1 hp Straight-Line Pencil Grinder, 60,000 RPM, 1/8" Collet

1 × $634.00 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60 -

×

ACS 1/2 in x 18 in Diamond Metal Bond Belt, 120M/125u

1 × $30.00

ACS 1/2 in x 18 in Diamond Metal Bond Belt, 120M/125u

1 × $30.00 -

×

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 16166, 3M PTFE Film Tape 5480, Gray, 1 in x 36 yd, 3.7 mil, 9 rolls per case,Boxed, 7000050128

$130.01

This item has been Discontinued.

3M PTFE Skived Film Tape 5480 uses a skived, polytetrafluoroethylene (PTFE), conformable film backing. This tape offers an extremely low coefficient of friction which, in combination with a pressure sensitive silicone adhesive, creates a smooth, non-stick surface over a variety of substrates to assist in the movement of web materials in many types of roll-wrap applications.