-

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

2 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

2 × $129.94 -

×

Dynabrade 51703 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 1/8" Collet

1 × $558.00

Dynabrade 51703 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 1/8" Collet

1 × $558.00 -

×

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33 -

×

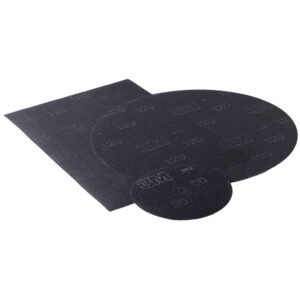

3M 29850, Sanding Screen, 120 Grit, 15 in x NH, 7100160830

12 × $4.47

3M 29850, Sanding Screen, 120 Grit, 15 in x NH, 7100160830

12 × $4.47 -

×

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03 -

×

Dynabrade 95684 1/4" Male Coupler

1 × $26.80

Dynabrade 95684 1/4" Male Coupler

1 × $26.80 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

500 × $0.73 -

×

Norton 66261014897 2" x 1/4" Bear-Tex NEX Rapid Blend AO Medium Grit TR (Type III) Non-Woven Wheel, 60 Each

60 × $4.78

Norton 66261014897 2" x 1/4" Bear-Tex NEX Rapid Blend AO Medium Grit TR (Type III) Non-Woven Wheel, 60 Each

60 × $4.78 -

×

Dynabrade 55501 .1hp Pencil Grinder, Twin Turbine, 100,000 RPM, Nickel-Plated Aluminum Housing, 3mm Collet

1 × $529.55

Dynabrade 55501 .1hp Pencil Grinder, Twin Turbine, 100,000 RPM, Nickel-Plated Aluminum Housing, 3mm Collet

1 × $529.55 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76 -

×

Dynabrade 92118 1/4" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.15

Dynabrade 92118 1/4" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.15 -

×

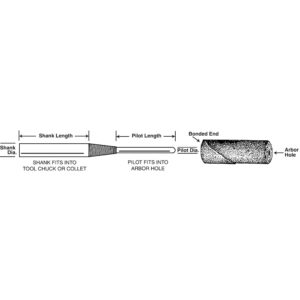

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

2 × $1,245.00

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

2 × $1,245.00 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

Dynabrade 40381 Dynafile II Abrasive Belt Tool, Slow Speed

1 × $924.00

Dynabrade 40381 Dynafile II Abrasive Belt Tool, Slow Speed

1 × $924.00 -

×

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

36 × $18.24

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

36 × $18.24 -

×

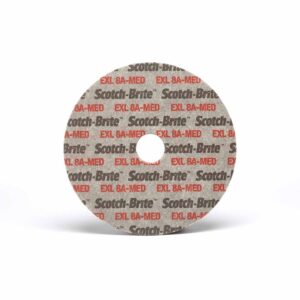

3M 14753, Scotch-Brite EXL Unitized Wheel, XL-UW, 8A Medium, 3 in x 1/4 in x 3/8 in, 7000000700

40 × $10.46

3M 14753, Scotch-Brite EXL Unitized Wheel, XL-UW, 8A Medium, 3 in x 1/4 in x 3/8 in, 7000000700

40 × $10.46 -

×

Dynabrade 51702 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 3/32" Collet

1 × $558.00

Dynabrade 51702 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 3/32" Collet

1 × $558.00 -

×

3M 21463, Marine Adhesive Sealant 5200, White, 5 Gallon Drum (Pail), 7010325698

1 × $1,029.08

3M 21463, Marine Adhesive Sealant 5200, White, 5 Gallon Drum (Pail), 7010325698

1 × $1,029.08 -

×

3M 86431, Scotch-Weld Multi-Material Composite Urethane Adhesive DP6330NS,Green, 48.5 mL Duo-Pak, 7100109828, 12/Case

12 × $18.04

3M 86431, Scotch-Weld Multi-Material Composite Urethane Adhesive DP6330NS,Green, 48.5 mL Duo-Pak, 7100109828, 12/Case

12 × $18.04 -

×

Dynabrade 51632 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $603.00

Dynabrade 51632 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $603.00 -

×

3M 95412, Lead Foil Tape 420, Dark Silver, 3/4 in x 36 yd, 6.8 mil, 7000029006

12 × $103.27

3M 95412, Lead Foil Tape 420, Dark Silver, 3/4 in x 36 yd, 6.8 mil, 7000029006

12 × $103.27

3M 04721, Double Coated Tape 444, Clear, 3/4 in x 36 yd, 3.9 mil, 7010302009

$23.66

Factory Stock, 7-10 Day Leadtime

3M Double Coated Tape 444 features our 3M Adhesive 300, a medium-firm acrylic adhesive ideal for joining materials that are smooth, thin and have low residual stress. It is excellent for foams and LSE plastics such as polyethylene, as well as HSE plastics. Adhesive is applied to both sides of a 0.5 mil PET film which adds structural stability. This tape features a 55# densified kraft liner.

A Double Coated Tape for Foams and LSE Plastics

Excellent for textured plastics, foams, fabrics and coated papers, 3M™ Double Coated Tape 444 features 3M™ Adhesive 300 on a 0.5 mil polyester (PET) film carrier. The medium-firm acrylic adhesive delivers high initial and final adhesion for efficient laminating procedures. The durable polyester film carrier between the adhesive layers improves the handling and strength of the tape, and adds stability during processes such as die-cutting and slitting. The adhesive is applied at 1.4 mils on the liner side and 2 mils on the face side for effective wet-out. The 55# densified kraft paper release liner makes for fast, efficient application.

About Our 3M™ Adhesive 300

3M™ Adhesive 300 is a medium-firm acrylic adhesive system featuring both high initial adhesion and good UV and chemical resistance and strong holding power. The design of the adhesive results in high initial adhesion and good temperature performance. The formulation gives 3M™ Adhesive 300 a consistently strong bond across a range of temperatures up to 250F/121C short term.

Recommended Applications:

- Medical diagnostic test strips

- Plastic film lamination/bonding

- Splicing

- Foam lamination

- Gasket attachment

What is Double Coated Tape?

In general, double coated tape is composed of a paper, film, or tissue carrier that is coated on both sides with pressure sensitive adhesive. The adhesive is protected by a peel-away liner that is removed at the time of application. These tapes can be applied by hand or with a dispenser. Double coated tape dispensers are available in a variety of configurations ranging from manual to fully automatic. Applications for double coated tape are found in electronics, automotive, aerospace, general industrial, and fabrication markets.

Bringing Better Ideas to the Surface through Science

In our 3M Industrial Adhesives and Tapes Division, we apply the science of adhesion to deliver innovative solutions that improve the design and manufacturing processes of companies around the world. In the end, our technologies help customers like you deliver competitive products to the market faster and more efficiently.