-

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00 -

×

Dynabrade 52374 4" (102 mm) Dia. Straight-Line Type 1 Wheel Grinder, 1 HP, 15,000 RPM, 3/8"-24 Spindle

1 × $676.00

Dynabrade 52374 4" (102 mm) Dia. Straight-Line Type 1 Wheel Grinder, 1 HP, 15,000 RPM, 3/8"-24 Spindle

1 × $676.00 -

×

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00 -

×

3M 19077, E-A-R, Soft FX Probed Test Plugs 393-2004-50, 50 EA/Case, 7000052883

1 × $100.28

3M 19077, E-A-R, Soft FX Probed Test Plugs 393-2004-50, 50 EA/Case, 7000052883

1 × $100.28 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00 -

×

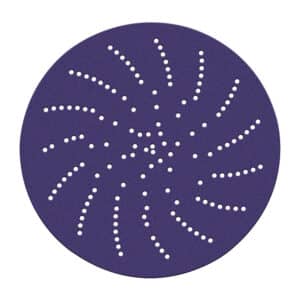

3M 28120, Hookit Clean Sanding Disc 900DZ, 5 in 60 J-weight, Die 500LG, 7010326613

250 × $1.51

3M 28120, Hookit Clean Sanding Disc 900DZ, 5 in 60 J-weight, Die 500LG, 7010326613

250 × $1.51 -

×

Insize 7101-300A, DIGITAL HORIZONTAL SCALE, 12"/300mm, 6928640321535

1 × $233.95

Insize 7101-300A, DIGITAL HORIZONTAL SCALE, 12"/300mm, 6928640321535

1 × $233.95 -

×

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,520.00

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,520.00 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00 -

×

3M 13718, Scotch-Brite EXL Unitized Wheel, XL-UW, 2S Fine, 3 in x 3/4 in x 1/4 in, 7000046025

10 × $18.37

3M 13718, Scotch-Brite EXL Unitized Wheel, XL-UW, 2S Fine, 3 in x 3/4 in x 1/4 in, 7000046025

10 × $18.37

3M 04721, Double Coated Tape 444, Clear, 3/4 in x 36 yd, 3.9 mil, 7010302009

$23.66

Factory Stock, 7-10 Day Leadtime

3M Double Coated Tape 444 features our 3M Adhesive 300, a medium-firm acrylic adhesive ideal for joining materials that are smooth, thin and have low residual stress. It is excellent for foams and LSE plastics such as polyethylene, as well as HSE plastics. Adhesive is applied to both sides of a 0.5 mil PET film which adds structural stability. This tape features a 55# densified kraft liner.

A Double Coated Tape for Foams and LSE Plastics

Excellent for textured plastics, foams, fabrics and coated papers, 3M™ Double Coated Tape 444 features 3M™ Adhesive 300 on a 0.5 mil polyester (PET) film carrier. The medium-firm acrylic adhesive delivers high initial and final adhesion for efficient laminating procedures. The durable polyester film carrier between the adhesive layers improves the handling and strength of the tape, and adds stability during processes such as die-cutting and slitting. The adhesive is applied at 1.4 mils on the liner side and 2 mils on the face side for effective wet-out. The 55# densified kraft paper release liner makes for fast, efficient application.

About Our 3M™ Adhesive 300

3M™ Adhesive 300 is a medium-firm acrylic adhesive system featuring both high initial adhesion and good UV and chemical resistance and strong holding power. The design of the adhesive results in high initial adhesion and good temperature performance. The formulation gives 3M™ Adhesive 300 a consistently strong bond across a range of temperatures up to 250F/121C short term.

Recommended Applications:

- Medical diagnostic test strips

- Plastic film lamination/bonding

- Splicing

- Foam lamination

- Gasket attachment

What is Double Coated Tape?

In general, double coated tape is composed of a paper, film, or tissue carrier that is coated on both sides with pressure sensitive adhesive. The adhesive is protected by a peel-away liner that is removed at the time of application. These tapes can be applied by hand or with a dispenser. Double coated tape dispensers are available in a variety of configurations ranging from manual to fully automatic. Applications for double coated tape are found in electronics, automotive, aerospace, general industrial, and fabrication markets.

Bringing Better Ideas to the Surface through Science

In our 3M Industrial Adhesives and Tapes Division, we apply the science of adhesion to deliver innovative solutions that improve the design and manufacturing processes of companies around the world. In the end, our technologies help customers like you deliver competitive products to the market faster and more efficiently.