-

×

3M 91461, Scotch Packaging Tape 3450S-RD-36GC, 1.88 in x 38.2 yd (48 mm x 35 m), 7100260773

36 × $4.82

3M 91461, Scotch Packaging Tape 3450S-RD-36GC, 1.88 in x 38.2 yd (48 mm x 35 m), 7100260773

36 × $4.82 -

×

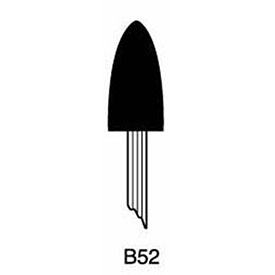

Dynabrade 78709 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

10 × $1.57

Dynabrade 78709 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

10 × $1.57 -

×

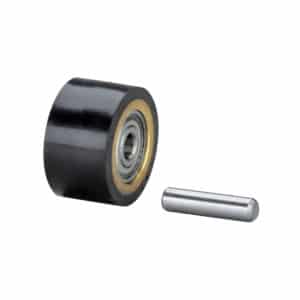

Dynabrade 01794 Rubber Drive Wheel

1 × $299.83

Dynabrade 01794 Rubber Drive Wheel

1 × $299.83 -

×

Dynabrade 78055 1" W x 24" L Medium NWN DynaBrite Belt, 10/pack

10 × $9.46

Dynabrade 78055 1" W x 24" L Medium NWN DynaBrite Belt, 10/pack

10 × $9.46 -

×

Dynabrade 95216 Pin

3 × $2.07

Dynabrade 95216 Pin

3 × $2.07 -

×

Standard Abrasives 713096, Aluminum Oxide Handy Roll, P220 J-weight, 1 in x 50 yd, 7010369522

1 × $26.59

Standard Abrasives 713096, Aluminum Oxide Handy Roll, P220 J-weight, 1 in x 50 yd, 7010369522

1 × $26.59 -

×

Standard Abrasives 708907, A/O Straight Cartridge Roll, 3/16 in x 1 in x 3/32 in 180, 7100103125

100 × $0.36

Standard Abrasives 708907, A/O Straight Cartridge Roll, 3/16 in x 1 in x 3/32 in 180, 7100103125

100 × $0.36 -

×

Dynabrade 56205 5" Dia. Non-Vacuum Disc Pad, Vinyl-Face

2 × $18.68

Dynabrade 56205 5" Dia. Non-Vacuum Disc Pad, Vinyl-Face

2 × $18.68 -

×

3M 93947, Scotch Stucco Tape 3260-A, 1.88 in x 60 yd (48 mm x 54.8 m), Stucco Tape, 7010384961

12 × $6.60

3M 93947, Scotch Stucco Tape 3260-A, 1.88 in x 60 yd (48 mm x 54.8 m), Stucco Tape, 7010384961

12 × $6.60 -

×

Dynabrade 78538 3/4"Dia. 2-Set, 3-48 Female Center Thread, 80 Grit, Dynacut A/O Overlap Slotted Disc, 100/pack

100 × $1.10

Dynabrade 78538 3/4"Dia. 2-Set, 3-48 Female Center Thread, 80 Grit, Dynacut A/O Overlap Slotted Disc, 100/pack

100 × $1.10 -

×

3M 90931, Scotch Tough Grip Moving Packaging Tape 3500S-21RD-3GC, 1.88 in x 38.2 yd (48 mm x 35 m) 2 pack, 7100253394

3 × $8.00

3M 90931, Scotch Tough Grip Moving Packaging Tape 3500S-21RD-3GC, 1.88 in x 38.2 yd (48 mm x 35 m) 2 pack, 7100253394

3 × $8.00 -

×

Dynabrade 13310 Mini-Dynisher Finishing Tool Versatility Kit, .4 HP, Rear Exhaust, 3,200 RPM, 5/8" Arbor

1 × $1,197.00

Dynabrade 13310 Mini-Dynisher Finishing Tool Versatility Kit, .4 HP, Rear Exhaust, 3,200 RPM, 5/8" Arbor

1 × $1,197.00 -

×

Dynabrade 90368 3/4" W x 34" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $2.55

Dynabrade 90368 3/4" W x 34" L 80 Grit A/O DynaCut Belt, 50/pack

50 × $2.55 -

×

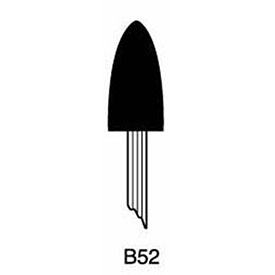

Dynabrade 78724 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

10 × $1.57

Dynabrade 78724 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

10 × $1.57 -

×

Dynabrade 90268 3" W x 10-11/16" L 180 Grit A/O DynaCut Belt, 10/pack

10 × $3.71

Dynabrade 90268 3" W x 10-11/16" L 180 Grit A/O DynaCut Belt, 10/pack

10 × $3.71 -

×

Dynabrade 90499 1/2" W x 34" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $2.27

Dynabrade 90499 1/2" W x 34" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $2.27 -

×

Dynabrade 59380 Rotor/Vane Set

2 × $71.27

Dynabrade 59380 Rotor/Vane Set

2 × $71.27 -

×

3M 11149, Scotchrap Vinyl Corrosion Protection Tape 50, 1 in x 100 ft,Unprinted, Black, 1 roll/carton, 10 rolls/Case, 7000057501

10 × $18.41

3M 11149, Scotchrap Vinyl Corrosion Protection Tape 50, 1 in x 100 ft,Unprinted, Black, 1 roll/carton, 10 rolls/Case, 7000057501

10 × $18.41 -

×

Dynabrade 13506 Dynastraight Finishing Tool, 1 HP, Rear Exhaust, 3,400 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $996.00

Dynabrade 13506 Dynastraight Finishing Tool, 1 HP, Rear Exhaust, 3,400 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $996.00 -

×

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $36.60

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $36.60 -

×

3M 79911, Scotch Long Lasting Storage Pkg Tape with dispenser 3650-RD-12GC, 1.88 in x 54.6 yd (48 mm x 50 m), Refillable Dispenser, 7100234261

12 × $5.70

3M 79911, Scotch Long Lasting Storage Pkg Tape with dispenser 3650-RD-12GC, 1.88 in x 54.6 yd (48 mm x 50 m), Refillable Dispenser, 7100234261

12 × $5.70 -

×

3M 15095, Scotch Heavy Duty Masking Tape 2020+-48TP6, 1.88 in x 60.1 yd (48mm x55m), 6 rolls/pack, 7100191056

4 × $22.27

3M 15095, Scotch Heavy Duty Masking Tape 2020+-48TP6, 1.88 in x 60.1 yd (48mm x55m), 6 rolls/pack, 7100191056

4 × $22.27 -

×

Dynabrade 92115 1/2" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.29

Dynabrade 92115 1/2" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.29 -

×

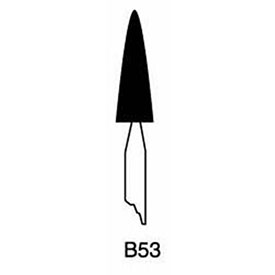

Dynabrade 78710 5/16" x 5/8"-B53 Dynacut A/O Mounted Point, 5/pack

5 × $1.57

Dynabrade 78710 5/16" x 5/8"-B53 Dynacut A/O Mounted Point, 5/pack

5 × $1.57

3M 08009, UHMW Film Tape 5421, Transparent, 2 in x 18 yd, 6.7 mil, 6 rolls percase, 7000050076

$172.26

Factory Stock, 7-10 Day Leadtime

Used to protect surfaces from abrasion, 3M UHMW-PE Film Tape 5421 is a thin caliper general purpose polyethylene tape that creates a “slip plane” effect to allow contact without wear. This tape features a unique combination of properties that make it ideal for many tough impact wear or sliding applications. 3M UHMW-PE Film Tape 5421 is a thinner version of 3M UHMW-PE Film Tape 5423.