-

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

ACS Diamond Cloth Belt, CX1250 1/2" X 72" 125U

12 × $23.20

ACS Diamond Cloth Belt, CX1250 1/2" X 72" 125U

12 × $23.20 -

×

Dynabrade 96101 Dynabrade Air Lube 10W/NR 24 Per Box

1 × $385.42

Dynabrade 96101 Dynabrade Air Lube 10W/NR 24 Per Box

1 × $385.42 -

×

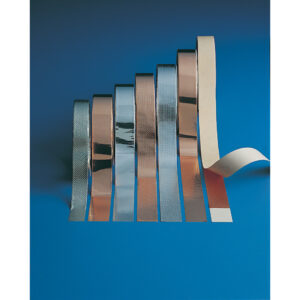

3M 27551, EMI Copper Foil Shielding Tape 1181, 1/2 in x 18 yd (12.70 mm x 16.5m), 7000132182

18 × $39.89

3M 27551, EMI Copper Foil Shielding Tape 1181, 1/2 in x 18 yd (12.70 mm x 16.5m), 7000132182

18 × $39.89 -

×

3M 49456, EMI Aluminum Foil Shielding Tape 1170, 2 in x 18 yd, 1170-2"X18YD, 7000132702

5 × $168.38

3M 49456, EMI Aluminum Foil Shielding Tape 1170, 2 in x 18 yd, 1170-2"X18YD, 7000132702

5 × $168.38 -

×

3M 16580, Accuspray ONE Spray Gun System with Standard PPS, 7100099202

4 × $337.64

3M 16580, Accuspray ONE Spray Gun System with Standard PPS, 7100099202

4 × $337.64 -

×

3M 37852, Dirt Trap Protection Material, Gray, 28 in x 300 ft, 7100132343

1 × $551.92

3M 37852, Dirt Trap Protection Material, Gray, 28 in x 300 ft, 7100132343

1 × $551.92 -

×

3M 20908, PSA Cloth Disc 348D, P100 X-weight, 2 in x NH, Die 200P, 7000118874

200 × $0.74

3M 20908, PSA Cloth Disc 348D, P100 X-weight, 2 in x NH, Die 200P, 7000118874

200 × $0.74 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58 -

×

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71 -

×

3M 49936, Roloc Disc 361F, 36 YF-weight, TSM, 2 in, Die RS200PM, 7000119014

200 × $1.15

3M 49936, Roloc Disc 361F, 36 YF-weight, TSM, 2 in, Die RS200PM, 7000119014

200 × $1.15 -

×

3M 20930, PSA Cloth Disc 348D, P120 X-weight, 1 in x NH, Die 100N, 7000118916

500 × $0.39

3M 20930, PSA Cloth Disc 348D, P120 X-weight, 1 in x NH, Die 100N, 7000118916

500 × $0.39 -

×

3M 29860, Sanding Screen, 120 grit, 12 in x 18 in, 7100160860

20 × $5.05

3M 29860, Sanding Screen, 120 grit, 12 in x 18 in, 7100160860

20 × $5.05 -

×

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

1000 × $0.67

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

1000 × $0.67 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

3M 14593, Scotch-Brite Cut and Polish Disc, 3" x 1-1/4" x 1/4" A Medium, D5, 7000045941, Box of 10

10 × $16.71

3M 14593, Scotch-Brite Cut and Polish Disc, 3" x 1-1/4" x 1/4" A Medium, D5, 7000045941, Box of 10

10 × $16.71 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60 -

×

3M 25125, Scotch-Weld Threadlocker TL71, Red, 1 mL Pipette, 7010330204, 100/case

100 × $1.85

3M 25125, Scotch-Weld Threadlocker TL71, Red, 1 mL Pipette, 7010330204, 100/case

100 × $1.85

3M 05098, Acryl Putty, Red, 14.5 oz, 7000045481

$27.18

Factory Stock, 7-10 Day Leadtime

3M Acryl Putty restores smooth surfaces by filling small pinholes, scratches, stone chips and other minor blemishes in automotive and marine finishes. Our acrylic putty offers easy sanding, smooth spreading and low shrinkage.

Patch Minor Imperfections

3M™ Acryl Putty fills minor surface blemishes in cars, trucks, vans, boats and other vehicles. Our acrylic glazing putty offers excellent workability with easy and smooth spreadability that effectively conceals pinholes, sand scratches and other spot repairs. Once the putty fully cures, you’ll appreciate its low rate of shrinkage and excellent adhesion to the surface.

Better Feathering Means Less Work

Our spot putty offers high quality feathering properties, meaning it is easy to smooth out the edges to blend with the surrounding surface. Good feathering will produce more satisfactory results and reduce sanding.

Choose the Putty that’s Right for You

3M™ Acryl Putty comes in multiple formulas offering different rates of drying, working time and sanding time. Use these numbers as estimates only. Actual drying, work and sanding times will vary depending on environmental conditions.

Formulas Include:

- 3M™ Acryl-White Putty is a slow drying formula with a 2.5 minute work time and 25 minute sanding time

- 3M™ Acryl-Red Putty is a medium drying formula with 2 minute work time and 20 minute sanding time

- 3M™ Acryl-Green Putty is a fast drying formula with a 1.5 minute work time and 15 minute sanding time

Directions for Use:

- Do not apply when ambient temperatures are below 55ºF or above 110ºF. Use in a well ventilated area away from sparks or open flame. (Do not apply material below the water line unless top coating.)

- For best results apply only over clean primed surfaces. (Use compressed air to remove any dust contamination).

- Apply using a plastic or metal spreader pressing the putty firmly into the imperfections; keep the application thickness to 1/16″ or less. Apply in thin coats instead of one thick application.

- Allow to dry prior to sanding. Sand (wet or dry) using 3M™ abrasives in the following sequence: P180, P220, P320. Note: As with any putty, longer drying times will occur with high humidity, thick applications and low temperatures.

- Re-clean surface prior to priming or top coating. (Follow paint manufacturer’s recommendation for priming and top coating).

Related products

Adhesives & Sealants

3M 25143, Scotch-Weld Threadlocker TL77, Red, 50 mL Bottle, 7100039225, 10/case

$33.94

Adhesives & Sealants

3M 62614, Scotch-Weld Threadlocker TL71, Red, 250 mL Bottle, 7100039230, 2/case

$126.95