-

×

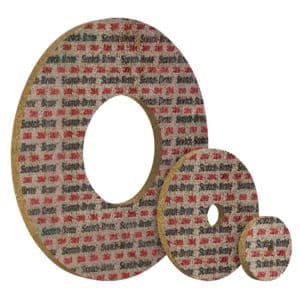

3M 15913, Scotch-Brite Roloc Disc High Strength, TR, 2 in X NH A Medium, 7000000710

200 × $1.72

3M 15913, Scotch-Brite Roloc Disc High Strength, TR, 2 in X NH A Medium, 7000000710

200 × $1.72 -

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $28,988.00 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00 -

×

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

1000 × $0.73

3M 11137, Roloc Disc 361F, 50 YF-weight, TR, 1-1/2 in, Die R150S, 7000045094

1000 × $0.73 -

×

Dynabrade 78596 3/8" Dia. x 1-1/2" W x 1/8" Center Hole, 120 Grit, 100/pack

100 × $50.00

Dynabrade 78596 3/8" Dia. x 1-1/2" W x 1/8" Center Hole, 120 Grit, 100/pack

100 × $50.00 -

×

3M 45528, Cloth Spiral Band 341D, P180 X-weight, 1 in x 1 in, 7010309037

100 × $0.60

3M 45528, Cloth Spiral Band 341D, P180 X-weight, 1 in x 1 in, 7010309037

100 × $0.60 -

×

3M 80782, Cloth Spiral Band 747D, 1 in x 1 in P120 X-weight, 7010328805

200 × $0.97

3M 80782, Cloth Spiral Band 747D, 1 in x 1 in P120 X-weight, 7010328805

200 × $0.97 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06 -

×

ACS Flap Disc, Type 29 (Curved) Full Diamond 4-1/2 X 5/8-11 60M, 333.FD4.5-60/T29

1 × $52.00

ACS Flap Disc, Type 29 (Curved) Full Diamond 4-1/2 X 5/8-11 60M, 333.FD4.5-60/T29

1 × $52.00 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76 -

×

Dynabrade 92120 1/4" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.15

Dynabrade 92120 1/4" W x 12" L 320 Grit A/O DynaCut Belt, 50/pack

50 × $1.15 -

×

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98 -

×

Dynabrade 90211 1/8" W x 18" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.10

Dynabrade 90211 1/8" W x 18" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.10 -

×

Dynabrade 02651 Bearing

1 × $18.65

Dynabrade 02651 Bearing

1 × $18.65 -

×

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50 -

×

Dynabrade 91167 1/2" W x 13" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $1.95

Dynabrade 91167 1/2" W x 13" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $1.95 -

×

3M 19677, Scotch-Seal Industrial Sealant 800, Reddish Brown, 1 Gallon Drum, 7000000793, 4/Case

4 × $251.59

3M 19677, Scotch-Seal Industrial Sealant 800, Reddish Brown, 1 Gallon Drum, 7000000793, 4/Case

4 × $251.59

3M 39861, Adhesion Promoter K500, 1 L Can, 7000008223

$51.61

Factory Stock, 7-10 Day Leadtime

3M Adhesion Promoter K500 is a liquid promoter used to improve the adhesion of 3M Acrylic Foam Tapes to most ethylene propylene diene monomer (EPDM), polypropylene (PP), chlorinated rubbers, acrylonitrile butadiene styrene (ABS) and certain polyethylene terephthalate (PET)/polybutylene terephthalate (PBT) blends used in automotive exterior trim applications.

Versatile Adhesion Promoter for 3M™ Acrylic Foam Tapes in Automotive Applications

3M™ Adhesion Promoter K500 is a liquid promoter used for most EPDM, polypropylene, chlorinated rubbers, ABS, AES compounds and certain PET/PBT blends. Since formulations and surface energies for these materials vary, each application should be verified through testing. 3M™ Adhesion Promoter K500 is a moisture cured system that is specifically formulated for use with 3M™ Acrylic Foam Tapes for automotive applications.

Preparing the Surface Before Application

The bonding surface should be clean and dry. Contaminated surfaces should be cleaned with an untreated, lint-free cloth and 3M™ General Purpose Adhesive Cleaner (Part No. 08984) or 3M™ Prep Solvent 70 (low VOC cleaner, Part No. 08973). Follow this by wiping with another untreated, lint-free cloth and isopropyl alcohol.

Easy to Apply

Apply a thin, uniform coating to the bonding surface using the minimum amount that will fully coat the surface. This is typically less than 0.002 inch thick. Allow the adhesion promoter to dry thoroughly before applying tape. Although this is usually accomplished in less than one minute, allowing 10 minutes yields the ultimate adhesion. For best results apply tape within 30 minutes after application of primer. Be sure the primed surface remains free from contaminants prior to laminating the tape. For clean-up tasks, 3M Adhesion Promoter K500 can be removed with acetone solvent.

Required Equipment for Application

3M™ Adhesion Promoter K500 can be applied with a felt tip applicator, pressurized flow gun, knurled roller or other similar type applicator. Applicator heads should be cleaned or replaced regularly.

Recommended Applications

- ABS

- TPO

- EPDM

- PP

- TPV/TPE blends

Better Science for Better Adhesion from 3M

Since 1925 when a 3M lab assistant invented masking tape, 3M has been applying science to life –developing adhesive products and technologies that help entire industries and individual businesses worldwide. The work that began with a single 3M engineer now spans decades and generations and all of it goes into each 3M product developed for automotive OEM, like 3M™ Adhesion Promoter K500.

Related products

Adhesives & Sealants

3M 62604, Scotch-Weld Threadlocker TL42, Blue, 1 mL Pipette, 7100064043, 100/case

$2.15

Unitized/ Deburring Wheels

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

$531.70