-

×

Dynabrade Rebel Series 53290 - 7" Type 41 Cut-Off Wheel Grinder

1 × $1,580.49

Dynabrade Rebel Series 53290 - 7" Type 41 Cut-Off Wheel Grinder

1 × $1,580.49 -

×

Dynabrade 78501 1" x 1/2", 8-32 Female Center Thread, 60 Grit, 8-Ply, Dynacut A/O Square Pad, 100/pack

100 × $4.08

Dynabrade 78501 1" x 1/2", 8-32 Female Center Thread, 60 Grit, 8-Ply, Dynacut A/O Square Pad, 100/pack

100 × $4.08 -

×

Dynabrade 57850 3-2/3" W x 7" L Non-Vacuum Dynabug Disc Pad, Vinyl-Face

1 × $32.11

Dynabrade 57850 3-2/3" W x 7" L Non-Vacuum Dynabug Disc Pad, Vinyl-Face

1 × $32.11 -

×

Dynabrade 52677 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 15,000 RPM, 1/4" Collet

1 × $728.59

Dynabrade 52677 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 15,000 RPM, 1/4" Collet

1 × $728.59 -

×

Dynabrade 90411 1/8" W x 24" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $0.79

Dynabrade 90411 1/8" W x 24" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $0.79 -

×

Dynabrade 78706 2" x 1/4"-20 Female Center Thread, Coarse, Dynabrite Surface Conditioning Eyelet Star, 50/pack

50 × $4.05

Dynabrade 78706 2" x 1/4"-20 Female Center Thread, Coarse, Dynabrite Surface Conditioning Eyelet Star, 50/pack

50 × $4.05 -

×

Dynabrade 52676 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 12,000 RPM, 1/4" Collet

1 × $728.59

Dynabrade 52676 1 hp Straight-Line 6" (152 mm) Extension Die Grinder, Rear Exhaust, 12,000 RPM, 1/4" Collet

1 × $728.59 -

×

Dynabrade 53891 Housing for Model 52541

1 × $102.11

Dynabrade 53891 Housing for Model 52541

1 × $102.11 -

×

Dynabrade 50302 4" (102 mm) Dia. Right Angle Depressed Center Wheel Grinder, 1 HP, 12,000 RPM, 3/8"-24 Spindle

1 × $1,233.26

Dynabrade 50302 4" (102 mm) Dia. Right Angle Depressed Center Wheel Grinder, 1 HP, 12,000 RPM, 3/8"-24 Spindle

1 × $1,233.26 -

×

Dynabrade 78663 1/2" Dia. x 1-1/2" W x 1/8" Center Hole, Tapered Cartridge Rolls, A/O, 60 Grit, 100/pack

100 × $1.20

Dynabrade 78663 1/2" Dia. x 1-1/2" W x 1/8" Center Hole, Tapered Cartridge Rolls, A/O, 60 Grit, 100/pack

100 × $1.20 -

×

Dynabrade 50281 4-1/2" Dia. Disc Pad, Spiral-Face, Medium Density, 5/8"-11 Thread

1 × $43.14

Dynabrade 50281 4-1/2" Dia. Disc Pad, Spiral-Face, Medium Density, 5/8"-11 Thread

1 × $43.14 -

×

Dynabrade 53031 - 5/32" Drill Chuck, 5/16"-24 Female Thread

1 × $114.40

Dynabrade 53031 - 5/32" Drill Chuck, 5/16"-24 Female Thread

1 × $114.40 -

×

Dynabrade 59469 Dynabug II Replacement Drop-In Motor

1 × $352.80

Dynabrade 59469 Dynabug II Replacement Drop-In Motor

1 × $352.80 -

×

Dynabrade 93608 3/4" Dia. x 3/8", 3-48 Female Center Thread, 240 Grit A/O, 8 Ply, J-DynaCut Cross Pad, 100/pack

100 × $1.58

Dynabrade 93608 3/4" Dia. x 3/8", 3-48 Female Center Thread, 240 Grit A/O, 8 Ply, J-DynaCut Cross Pad, 100/pack

100 × $1.58 -

×

Dynabrade 18439 Filter

1 × $2.73

Dynabrade 18439 Filter

1 × $2.73 -

×

Dynabrade 90438 2" W x 30" L Medium NWN DynaBrite Premium Belt, 10/pack

10 × $26.78

Dynabrade 90438 2" W x 30" L Medium NWN DynaBrite Premium Belt, 10/pack

10 × $26.78 -

×

Dynabrade 58441 5" Dia. Two-Hand Gear-Driven Sander, Non-Vacuum, .45 HP, 900 RPM, Hook-Face Pad

1 × $556.28

Dynabrade 58441 5" Dia. Two-Hand Gear-Driven Sander, Non-Vacuum, .45 HP, 900 RPM, Hook-Face Pad

1 × $556.28 -

×

Dynabrade 45246 Sleeve, for 47820, 12K RPM

1 × $40.56

Dynabrade 45246 Sleeve, for 47820, 12K RPM

1 × $40.56 -

×

Dynabrade 82566 3/4" W x 18" L 120 Grit Ceramic DynaCut Belt, 50/pack

50 × $2.81

Dynabrade 82566 3/4" W x 18" L 120 Grit Ceramic DynaCut Belt, 50/pack

50 × $2.81 -

×

Dynabrade 54029 Sanding Head

1 × $134.55

Dynabrade 54029 Sanding Head

1 × $134.55 -

×

Dynabrade 56182 6" Dia. Non-Vacuum Disc Pad, Hook-Face Short Nap

1 × $32.53

Dynabrade 56182 6" Dia. Non-Vacuum Disc Pad, Hook-Face Short Nap

1 × $32.53 -

×

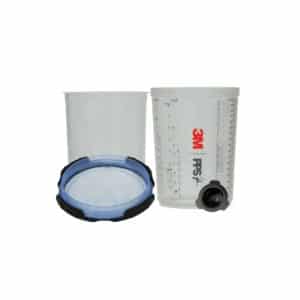

3M 26112, PPS Series 2.0 Spray Cup System Kit, Midi (13.5 fl oz, 400

mL), 200 Micron Filter, 7100169390

1 × $117.18

3M 26112, PPS Series 2.0 Spray Cup System Kit, Midi (13.5 fl oz, 400

mL), 200 Micron Filter, 7100169390

1 × $117.18

3M 55847, Dynamic Mixing System Nozzle, 50 per bag, 7000119977

$130.25

Factory Stock, 7-10 Day Leadtime, Priced Per Bag

Our 3M Dynamic Mixing System Nozzle is integral to fast, accurate mixing of two-part body repair products. Nozzles are specially designed for low-waste mixing that thoroughly blends material to specific ratios. Choose the DMS 1.0 red nozzle for fillers and glazes, and purple nozzles for DMS 1.5 adhesives and sealers. Nozzle extensions are available for adhesives and sealants to reduce bead size.