-

×

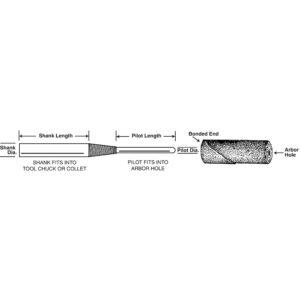

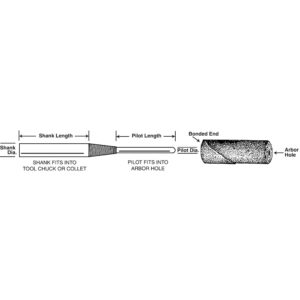

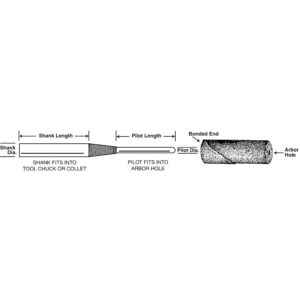

Standard Abrasives 704491, Cartridge Roll Mandrel, 3/16 in x 3/4 in x 1/4 in x 1 in x 2-3/4 in CM-15, 7000121768

5 × $4.88

Standard Abrasives 704491, Cartridge Roll Mandrel, 3/16 in x 3/4 in x 1/4 in x 1 in x 2-3/4 in CM-15, 7000121768

5 × $4.88 -

×

3M 62606, Scotch-Weld Threadlocker TL42, Blue, 50 mL Bottle, 7100039193, 10/case

10 × $42.72

3M 62606, Scotch-Weld Threadlocker TL42, Blue, 50 mL Bottle, 7100039193, 10/case

10 × $42.72 -

×

3M 05526, Wetordry Sponge Pad 20, 5-1/2 x 2-3/4 in x 3/8 in, 7000045663

100 × $6.21

3M 05526, Wetordry Sponge Pad 20, 5-1/2 x 2-3/4 in x 3/8 in, 7000045663

100 × $6.21 -

×

3M 27551, EMI Copper Foil Shielding Tape 1181, 1/2 in x 18 yd (12.70 mm x 16.5m), 7000132182

18 × $39.89

3M 27551, EMI Copper Foil Shielding Tape 1181, 1/2 in x 18 yd (12.70 mm x 16.5m), 7000132182

18 × $39.89 -

×

Standard Abrasives 717078, Cartridge Roll Mandrel, 3/32 in x 3/4 in x 1/4 in x 1 in x 2-3/4 in CM-2E, 7000121813

5 × $4.88

Standard Abrasives 717078, Cartridge Roll Mandrel, 3/32 in x 3/4 in x 1/4 in x 1 in x 2-3/4 in CM-2E, 7000121813

5 × $4.88 -

×

3M 20930, PSA Cloth Disc 348D, P120 X-weight, 1 in x NH, Die 100N, 7000118916

500 × $0.39

3M 20930, PSA Cloth Disc 348D, P120 X-weight, 1 in x NH, Die 100N, 7000118916

500 × $0.39 -

×

3M 47201, Polyurethane Sealant 540, Black, 600 mL Sausage Pack, 7100198009, 12/Case

12 × $14.30

3M 47201, Polyurethane Sealant 540, Black, 600 mL Sausage Pack, 7100198009, 12/Case

12 × $14.30 -

×

3M 09413, Scotch-Brite Contour Surface Paint and Varnish Remover 9413NA, 7000052005

10 × $5.79

3M 09413, Scotch-Brite Contour Surface Paint and Varnish Remover 9413NA, 7000052005

10 × $5.79 -

×

3M 62610, Scotch-Weld Threadlocker TL62, Red, 50 mL Bottle, 7100039196, 10/case

10 × $36.70

3M 62610, Scotch-Weld Threadlocker TL62, Red, 50 mL Bottle, 7100039196, 10/case

10 × $36.70 -

×

3M 49941, Roloc Disc 361F, 80 YF-weight, TSM, 3 in, Die RS300VM, 7000148151

200 × $1.33

3M 49941, Roloc Disc 361F, 80 YF-weight, TSM, 3 in, Die RS300VM, 7000148151

200 × $1.33 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

3M 77512, Cloth Belt 777F, 60 YF-weight, 1 in x 42 in, Film-lok, Single-flex, 7010307736, 200 per case

200 × $5.06

3M 77512, Cloth Belt 777F, 60 YF-weight, 1 in x 42 in, Film-lok, Single-flex, 7010307736, 200 per case

200 × $5.06 -

×

3M 07415, Hand Sanding Wood Finishing Pad 7415NA, 4.375 in x 11 in, Gray Fine, 7010383728

10 × $1.77

3M 07415, Hand Sanding Wood Finishing Pad 7415NA, 4.375 in x 11 in, Gray Fine, 7010383728

10 × $1.77 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

3M 19765, Utility Cloth Sheet 314D, 9 in x 11 in P280 J-weight, 7000000353

250 × $1.37

3M 19765, Utility Cloth Sheet 314D, 9 in x 11 in P280 J-weight, 7000000353

250 × $1.37 -

×

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22 -

×

Standard Abrasives 710870, Cartridge Roll Mandrel, 1/8 in x 1/2 in x 1/4 in x 1-1/4 in x 2-1/4 in CM-7, 7000121794

5 × $4.71

Standard Abrasives 710870, Cartridge Roll Mandrel, 1/8 in x 1/2 in x 1/4 in x 1-1/4 in x 2-1/4 in CM-7, 7000121794

5 × $4.71 -

×

Standard Abrasives 78530, Ceramic Pro Type 29 Flap Disc, 645145, 7 in x 7/8 40 Y-weight, 7010369548, 10 per case

10 × $12.78

Standard Abrasives 78530, Ceramic Pro Type 29 Flap Disc, 645145, 7 in x 7/8 40 Y-weight, 7010369548, 10 per case

10 × $12.78 -

×

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25

3M 22405, Roloc Disc 361F, P100 YF-weight, TR, 3 in, Die R300V, 7000045102

200 × $1.25 -

×

Dynabrade 69522 Housing for 69500, 5,000 RPM

1 × $77.04

Dynabrade 69522 Housing for 69500, 5,000 RPM

1 × $77.04 -

×

3M 47181, Polyurethane Adhesive Sealant 550FC Fast Cure, Black, 600 mL Sausage Pack, 7100197989, 12/Case

12 × $16.09

3M 47181, Polyurethane Adhesive Sealant 550FC Fast Cure, Black, 600 mL Sausage Pack, 7100197989, 12/Case

12 × $16.09 -

×

3M 15289, 663FC, 2-3/4" X 160", 40u, Diamond Trizact Belts 7010508900

1 × $2,343.05

3M 15289, 663FC, 2-3/4" X 160", 40u, Diamond Trizact Belts 7010508900

1 × $2,343.05 -

×

Dynabrade 51629 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $603.00

Dynabrade 51629 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $603.00 -

×

3M 34576, Cubitron II Net Sheet Roll, 220+, 115 mm x 10 m, 7100247509, 6 Rolls/Case

6 × $47.94

3M 34576, Cubitron II Net Sheet Roll, 220+, 115 mm x 10 m, 7100247509, 6 Rolls/Case

6 × $47.94 -

×

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57 -

×

3M 30708, Cloth Belt 577F, 120 YF-weight, 1/4 in x 18 in, Fabri-lok, Single-flex, 7010308884, 200 per case

200 × $1.40

3M 30708, Cloth Belt 577F, 120 YF-weight, 1/4 in x 18 in, Fabri-lok, Single-flex, 7010308884, 200 per case

200 × $1.40 -

×

3M 45706, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 5 in x NH, Die500X, 7100085514

200 × $1.78

3M 45706, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 5 in x NH, Die500X, 7100085514

200 × $1.78 -

×

3M 20227, Scotch-Seal Metal Sealant 2084, Silver, 5 oz Tube, 7000046343, 36/Case

36 × $23.01

3M 20227, Scotch-Seal Metal Sealant 2084, Silver, 5 oz Tube, 7000046343, 36/Case

36 × $23.01

3M 87180, Scotch-Weld Epoxy Adhesive 2216NS, Tan, Part A, 5 Gallon Drum (Pail), 7010367414

$614.69

Factory Stock, 7-10 Day Leadtime

3M Scotch-Weld Epoxy Adhesive 2216NS is a flexible, non-sag, two-part epoxy adhesive that cures at room temperature. It provides a high strength bond with both high shear and peel strength while remaining highly flexible, making it ideal for applications where vibration and thermal expansion and contraction are common. It also withstands very cold temperatures without becoming brittle.

When using a Duo-Pak (DP) size adhesive, rely on 3M dispensing equipment for convenient and accurate metering, mixing and dispensing.

Non-Sag Properties Provides Greater Bond Line Control

3M™ Scotch-Weld Epoxy Adhesive 2216NS is a non-sag version of our 3M™ Scotch-Weld Epoxy Adhesive 2216. It is designed for applications where high performance and flexible bonds are required. Its flexibility makes it ideal for applications involving dissimilar surfaces and where differing coefficients of thermal expansion are a consideration. Once fully cured the epoxy maintains an extremely strong bond under expansion, contraction and limited movement while also maintaining a good retention of strength over time and after environmental aging. With a 2:3 mix ratio it is a low viscosity epoxy. It flows smoothly for accurate dispensing. Both the base and accelerator are coded in contrasting colors to ensure you know which half of the product you are using.

Recommended Applications

- Hard disk drive component assembly

- Potting where expansion and thermal changes may occur, such as solar panels and other construction applications

- Military bonding applications, for example bonding parts on movable transports

- Bonding ceramic, most plastics and glass to metal

- Attaching various substrates to masonry and stone

- Excellent for Cryogenic Bonding Applications

Our 3M™ Scotch-Weld Epoxy Adhesive 2216NS is designed to perform under extremely frigid temperatures. Because it can withstand temperatures up to -423°F/-252°C it is ideal for cryogenic bonding applications. At room temperature it offers a 90 minute work life to allow for repositioning and adjustments. It will slowly cure over 7 days, but can be heat cured to reduce this to as little as 30 minutes (at 200°F/93°C.) It has a bonded shear strength that can withstand up to 3,200 psi at 72°F/24°C.

Understanding Epoxy Adhesives

Epoxy adhesives, including 5 minute epoxy are part of the class of adhesives called “structural adhesives,” which include polyurethane, acrylic, cyanoacrylate and others. Epoxies are formulated as liquid rea¬ctive polymers that undergo a chemical reaction when mixed and then cure to form a solid plastic material. Once the two parts are mixed in their specified ratio, they begin the curing process and offer a limited working time where the adhesive can be applied and the two surfaces positioned as needed. This work life lasts anywhere from a few minutes to several hours. These structural adhesives provide high shear and peel strengths, depending on the formula, and better heat and chemical resistance than other common adhesives. In general, epoxy adhesives have the highest overall strength and offer the best performance and most resistance to high temperatures, solvents and outdoor weathering.

Epoxy adhesive (often referred to as epoxy glue) is widely used in building and home construction; aircraft and automobile manufacturing; bicycle, boat, golf clubs, ski and snowboard assembly as well as a host of home use and other applications. It is used virtually anywhere high-strength bonds are needed along with resistance to environmental conditions. These adhesives are popular for their ease of use, mechanical strength and chemical resistance. Formulations can be created to make epoxy for plastic flexible or epoxy for metal rigid, epoxy resin transparent or opaque, quick setting or slow setting. The versatility with which these adhesives can be formulated helps meet almost any requirement for bonding wood, metal, glass, stone and various plastics.

Related products

Adhesives & Sealants

3M 41531, Scotch-Weld Epoxy Adhesive 420, Black, Part B, 5 Gallon Drum (Pail), 7000000827

$583.75