-

×

Dynabrade 51702 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 3/32" Collet

1 × $558.00

Dynabrade 51702 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 3/32" Collet

1 × $558.00 -

×

Dynabrade 51811 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/16" Collet

1 × $751.00

Dynabrade 51811 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/16" Collet

1 × $751.00 -

×

3M 57894, 642WY 1/4" X 24", 50000 Mesh Diamond Cloth Belt, 7100230570

15 × $0.00

3M 57894, 642WY 1/4" X 24", 50000 Mesh Diamond Cloth Belt, 7100230570

15 × $0.00 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

1000 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

1000 × $0.75 -

×

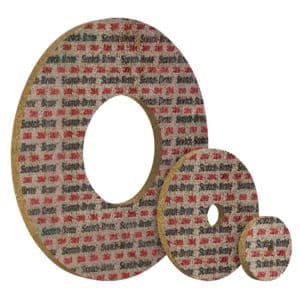

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60 -

×

3M 19772, Utility Cloth Sheet 314D, 9 in x 11 in P80 J-weight, 7000000359

250 × $1.45

3M 19772, Utility Cloth Sheet 314D, 9 in x 11 in P80 J-weight, 7000000359

250 × $1.45 -

×

3M 99297, Scotch-Weld Structural Plastic Adhesive DP8005, Off-White, 490 mLDuo-Pak, 7100090196, 6/case

6 × $317.12

3M 99297, Scotch-Weld Structural Plastic Adhesive DP8005, Off-White, 490 mLDuo-Pak, 7100090196, 6/case

6 × $317.12 -

×

3M 05203, Marine Adhesive Sealant 5200, White, 3 oz Tube, 7000118401, 6/Case

6 × $15.40

3M 05203, Marine Adhesive Sealant 5200, White, 3 oz Tube, 7000118401, 6/Case

6 × $15.40 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58 -

×

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21 -

×

ACS Diamond Cloth Belt, CX1250 3/8" X 24" 75U

16 × $5.80

ACS Diamond Cloth Belt, CX1250 3/8" X 24" 75U

16 × $5.80 -

×

Dynabrade 51750 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $603.00

Dynabrade 51750 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $603.00 -

×

Dynabrade 51740 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet, with Mount Stem

1 × $512.00

Dynabrade 51740 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet, with Mount Stem

1 × $512.00 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00 -

×

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76

3M Scotchkote Liquid Epoxy Coating Spray System HSS Mix Nozzle, RightAngle, 7000058900

24 × $168.76 -

×

3M 05049, Cloth Belt 384F, 80+ XF-weight, 1 in x 30 in, Fabri-lok, Full-flex, 7100141431, 200 per case

200 × $1.92

3M 05049, Cloth Belt 384F, 80+ XF-weight, 1 in x 30 in, Fabri-lok, Full-flex, 7100141431, 200 per case

200 × $1.92 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

Standard Abrasives 32985, Aluminum Oxide Overlap Disc, 714721, 60 Grit, 2 in x 8-32 x 2 Ply, 7100116380

100 × $1.67

Standard Abrasives 32985, Aluminum Oxide Overlap Disc, 714721, 60 Grit, 2 in x 8-32 x 2 Ply, 7100116380

100 × $1.67 -

×

Dynabrade 51810 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/8" Collet

1 × $751.00

Dynabrade 51810 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 1/8" Collet

1 × $751.00 -

×

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.98 -

×

3M 31583, Hi-Strength Postforming 94 CA Fragrance Free Cylinder Spray Adhesive, Red, Large Cylinder (Net Wt 26.2 lb), 7010329925

1 × $454.54

3M 31583, Hi-Strength Postforming 94 CA Fragrance Free Cylinder Spray Adhesive, Red, Large Cylinder (Net Wt 26.2 lb), 7010329925

1 × $454.54

3M 62660, Scotch-Weld Gasket Maker GM18, Red, 300 Gram Cartridge, 7010367433, 10/Case

This item has been Discontinued.

3M Scotch-Weld High Temperature Gasket Maker GM18 is a red, flexible, one-component anaerobic sealant formulated to replace pre-cut gaskets, O-rings or used as form-in-place gaskets. They cure at room temperature and seal rigid assemblies of any shape or size. They can be used to fill pits, scratches, and gouges in the flange surface without having to grind or skim the mating surfaces.