-

×

Dynabrade 53523 Polisher (Triple Extension), 1 HP, 3,400 RPM, 1/2"-20 Spindle Thread

1 × $1,662.72

Dynabrade 53523 Polisher (Triple Extension), 1 HP, 3,400 RPM, 1/2"-20 Spindle Thread

1 × $1,662.72 -

×

Dynabrade 79821 3" 320 Grit Dynacut Extreme Orange Film Non Vac Hook Face Disc, 50 per box

1 × $33.02

Dynabrade 79821 3" 320 Grit Dynacut Extreme Orange Film Non Vac Hook Face Disc, 50 per box

1 × $33.02 -

×

Dynabrade 52100 .5 hp Straight-Line Die Grinder, Rear Exhaust, 950 RPM, 1/4" Collet

1 × $917.51

Dynabrade 52100 .5 hp Straight-Line Die Grinder, Rear Exhaust, 950 RPM, 1/4" Collet

1 × $917.51 -

×

Dynabrade 56207 5" Dia. Vacuum Disc Pad, Vinyl-Face

1 × $16.84

Dynabrade 56207 5" Dia. Vacuum Disc Pad, Vinyl-Face

1 × $16.84 -

×

Dynabrade 56317 3-1/4" x 5" Non-Vacuum Dynabug II Disc Pad, Hook-Face, Short Nap

1 × $31.98

Dynabrade 56317 3-1/4" x 5" Non-Vacuum Dynabug II Disc Pad, Hook-Face, Short Nap

1 × $31.98 -

×

Dynabrade 51395 6"-8" (152 mm-203 mm) Dia. Right Angle Two-Hand Rotary Buffer

1 × $1,409.94

Dynabrade 51395 6"-8" (152 mm-203 mm) Dia. Right Angle Two-Hand Rotary Buffer

1 × $1,409.94 -

×

Dynabrade 54742 3" (76 mm) Dia. Extended Right Angle Type 1 Cut-Off Tool, Steel Housing, .7 HP, 18,000 RPM, 3/8"-24 Spindle

1 × $1,144.92

Dynabrade 54742 3" (76 mm) Dia. Extended Right Angle Type 1 Cut-Off Tool, Steel Housing, .7 HP, 18,000 RPM, 3/8"-24 Spindle

1 × $1,144.92 -

×

Dynabrade 90676 1" W x 30" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $2.11

Dynabrade 90676 1" W x 30" L 120 Grit A/O DynaCut Belt, 50/pack

50 × $2.11 -

×

Dynabrade 02673 Rear Bearing Plate

1 × $51.87

Dynabrade 02673 Rear Bearing Plate

1 × $51.87 -

×

Dynabrade 56107 6" Dia. Non-Vacuum Disc Pad, Vinyl-Face

1 × $27.37

Dynabrade 56107 6" Dia. Non-Vacuum Disc Pad, Vinyl-Face

1 × $27.37 -

×

Dynabrade 91537 5" Dynacut Extreme Orange Premium Film Disc, 100 Grit, Hook & Loop, Vacuum Holes, 50/Box

1 × $35.82

Dynabrade 91537 5" Dynacut Extreme Orange Premium Film Disc, 100 Grit, Hook & Loop, Vacuum Holes, 50/Box

1 × $35.82 -

×

Dynabrade Dynacut 94021, 10-piece, Alloy Specific Burr Kit (for Nickel & Titanium), 1/8" Shank

1 × $161.64

Dynabrade Dynacut 94021, 10-piece, Alloy Specific Burr Kit (for Nickel & Titanium), 1/8" Shank

1 × $161.64 -

×

Dynabrade 49430 Mini Angle Head Drill, .4 HP, Rear Exhaust, 3,200 RPM, 1/4"-28 Female Thread

1 × $1,200.03

Dynabrade 49430 Mini Angle Head Drill, .4 HP, Rear Exhaust, 3,200 RPM, 1/4"-28 Female Thread

1 × $1,200.03 -

×

Dynabrade 48371 .4 hp Straight-Line Die Grinder, Rear Exhaust, 25,000 RPM, 1/4" Collet

1 × $415.47

Dynabrade 48371 .4 hp Straight-Line Die Grinder, Rear Exhaust, 25,000 RPM, 1/4" Collet

1 × $415.47 -

×

Dynabrade 79836 3" 1000 Grit Dynacut Extreme Orange Film Non Vac Hook Face Disc, 50 per box

1 × $33.02

Dynabrade 79836 3" 1000 Grit Dynacut Extreme Orange Film Non Vac Hook Face Disc, 50 per box

1 × $33.02 -

×

Dynabrade 39000 1" Type C, Roto Peen Flaps, 1 Per Pack

1 × $36.05

Dynabrade 39000 1" Type C, Roto Peen Flaps, 1 Per Pack

1 × $36.05 -

×

Dynabrade 90449 1/2" W x 24" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.34

Dynabrade 90449 1/2" W x 24" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.34 -

×

Dynabrade 54430 4" Dia. Extended Right Angle Disc Sander, Steel Housing, Rear Exhaust, .7 HP, 12,000 RPM, 3/8"-24 Thread

1 × $1,134.42

Dynabrade 54430 4" Dia. Extended Right Angle Disc Sander, Steel Housing, Rear Exhaust, .7 HP, 12,000 RPM, 3/8"-24 Thread

1 × $1,134.42 -

×

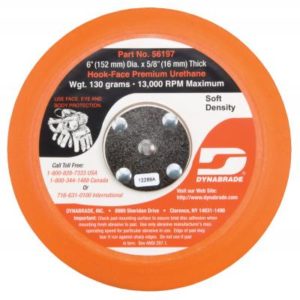

Dynabrade 56197 6" Dia. Non-Vacuum Disc Pad, Hook-Face, Short Nap

1 × $27.66

Dynabrade 56197 6" Dia. Non-Vacuum Disc Pad, Hook-Face, Short Nap

1 × $27.66 -

×

3M 08024, Adhesive Sealant 740 UV, Black, 290 mL Cartridge, 7100115542, 12 per case

12 × $16.25

3M 08024, Adhesive Sealant 740 UV, Black, 290 mL Cartridge, 7100115542, 12 per case

12 × $16.25

3M 41531, Scotch-Weld Epoxy Adhesive 420, Black, Part B, 5 Gallon Drum (Pail), 7000000827

$583.75

Factory Stock, 7-10 Day Leadtime

3M Scotch-Weld Epoxy Adhesive DP420 is a toughened, two-part epoxy structural adhesive that provides good strength along with high impact and fatigue resistance to meet demanding bonding challenges. 3M Scotch-Weld Epoxy Adhesive DP420 can replace mechanical fasteners, screws, rivets and spot welds in many applications.

When using a Duo-Pak (DP) size adhesive, rely on 3M dispensing equipment for convenient and accurate metering, mixing and dispensing.

Bonds stainless steel shaft into stainless steel club head

High Peel and Shear Strength Maintains Lasting Bond at High and Low Temperatures

3M™ Scotch-Weld™ Epoxy Adhesive DP420 maintains bond strength at high and low temperatures and can withstand paint bake operations up to 400°F for 60 minutes. It works well on a variety of substrates such as metals, ceramics, wood, glass, many composites and plastics, and is an excellent indoor bonding agent for joining, gluing, potting, panel bonding, and structural bonding. 3M™ Scotch-Weld™ Epoxy Adhesive DP420 Off-White meets the requirements for UL 94 HB.

Recommended Applications

- Small joint assembly

- Heavy-duty mounting assembly

- Metalworking

- Carbon fiber epoxy bonding

20 Minute Work Life Provides Time for Positioning and Adjustment

3M™ Scotch-Weld™ Epoxy Adhesive DP420 reaches handling strength in approximately two hours and is fully cured in 24 hours (at 72°F/22°C.) The mix ratio is 2:1 and provides a 20 minute work life, providing time to adjust for desired fit prior to curing. This adhesive is available in a variety of package sizes and can be dispensed in several ways to meet the demands of the user and the job.

Toughened for Impact and Fatigue Resistance

3M™ Scotch-Weld™ Epoxy Adhesive DP420 is appropriate for applications that will face tough environmental challenges. Formulated to provide strong adhesion for the long-term, this resilient epoxy is another way 3M applies their expertise to meet and exceed the demands of even the toughest applications.

What are Epoxy Adhesives?

Epoxy adhesives are part of the class of adhesives called “structural adhesives,” which also includes polyurethane, acrylic, cyanoacrylate and others. Epoxies are formulated as liquid reactive polymers that undergo a chemical reaction when mixed and then cure to form a solid plastic material. Once the two parts are mixed in their specified ratio, they begin the curing process and offer a limited work life (open time) where the adhesive can be applied and the two surfaces positioned as needed. This work life lasts anywhere from a few minutes to several hours. These structural adhesives provide high shear and peel strengths, depending on the formula, and better heat and chemical resistance than other common adhesives. In general, epoxy adhesives have the highest overall strength and offer the best performance and most resistance to high temperatures, solvents and outdoor weathering.

Epoxy adhesives are widely used in building and home construction; aircraft and automobile manufacturing; bicycle, boat, golf clubs, ski and snowboard assembly as well as a host of home use and other applications. They are used virtually anywhere high-strength bonds are needed along with resistance to environmental conditions. These adhesives are popular for their ease of use, mechanical strength and chemical resistance. Formulations can be created to make epoxies flexible or rigid, transparent or opaque, quick setting or slow setting. The versatility with which epoxy adhesives can be formulated helps meet almost any requirement for bonding wood, metal, glass, stone and various plastics.

Industrial uses for epoxies range widely and, in addition to adhesives, include coatings and composite materials like carbon fiber and glass-reinforced composites. They are the preferred choice due to their ability to flow and conform to the work area, strong adhesion, chemical and heat resistance and exceptional mechanical and electrical insulating properties.

Related products

Adhesives & Sealants

3M 08024, Adhesive Sealant 740 UV, Black, 290 mL Cartridge, 7100115542, 12 per case

$16.25

Adhesives & Sealants

3M 08367, Urethane Seam Sealer, Black, 310 mL Cartridge, 7000119968, 12 per case

$26.40