-

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58 -

×

3M 82618, Rubber and Vinyl Spray Adhesive 80, Yellow, 24 fl oz Can (Net Wt 19 oz), 7000028604, 6/Case

6 × $22.12

3M 82618, Rubber and Vinyl Spray Adhesive 80, Yellow, 24 fl oz Can (Net Wt 19 oz), 7000028604, 6/Case

6 × $22.12 -

×

Standard Abrasives 881110, A/O Unitized Wheel, 811, 2 in x 1/4 in x 1/4 in, 7010367104

10 × $6.86

Standard Abrasives 881110, A/O Unitized Wheel, 811, 2 in x 1/4 in x 1/4 in, 7010367104

10 × $6.86 -

×

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39 -

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38 -

×

3M 05009, Utility Cloth Roll 211K, 100 J-weight, 1 in x 50 yd, Full-flex, 7100016843

5 × $58.76

3M 05009, Utility Cloth Roll 211K, 100 J-weight, 1 in x 50 yd, Full-flex, 7100016843

5 × $58.76 -

×

Dynabrade 69522 Housing for 69500, 5,000 RPM

1 × $77.04

Dynabrade 69522 Housing for 69500, 5,000 RPM

1 × $77.04

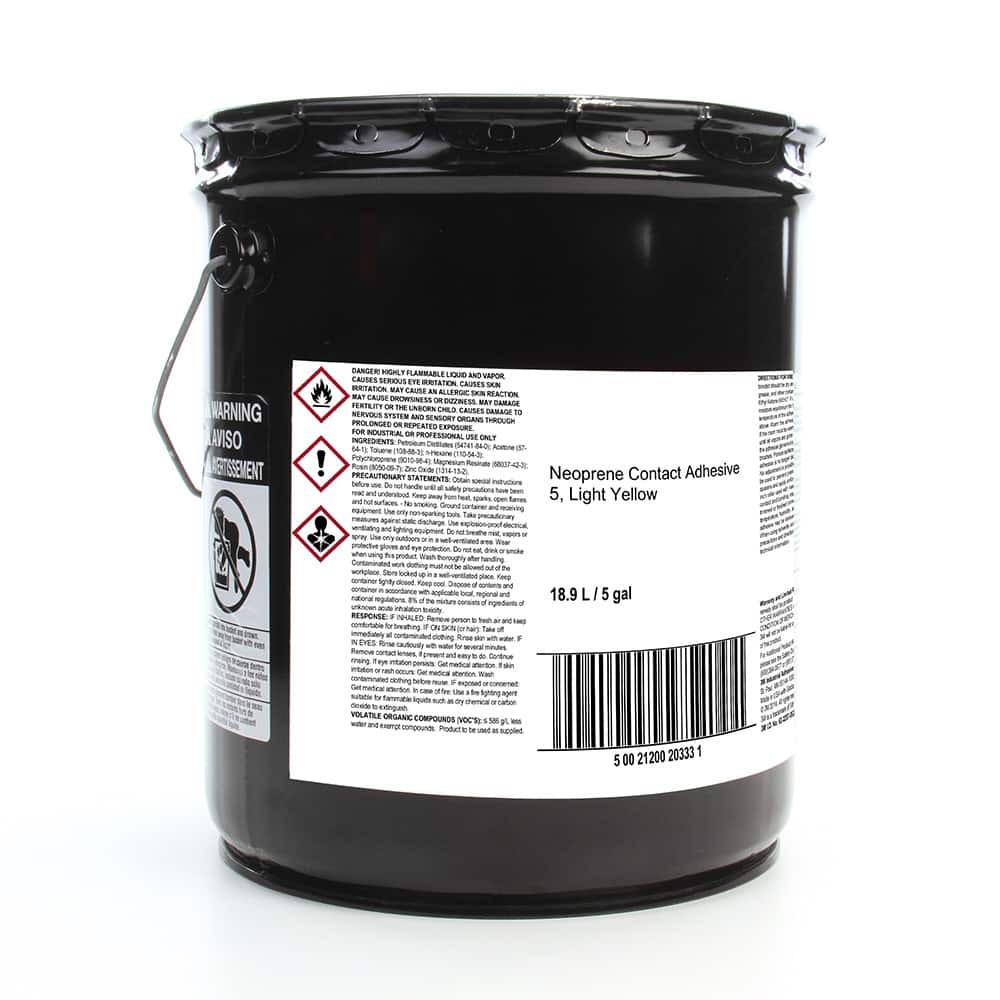

3M 20333, Neoprene Contact Adhesive 5, Light Yellow, 5 Gallon Drum (Pail), 7010367231

$64.47

Factory Stock, 7-10 Day Leadtime

3M Neoprene Contact Adhesive 5 is a versatile, solvent based adhesive with a low viscosity for spraying. It offers high immediate handling strength and good heat resistance, and is commonly used for bonding most metals and plastics. It is also suitable for large surface panel or composite lamination.