-

×

3M 29859, Sanding Screen, 100 grit, 12 in x 18 in, 7100160861

20 × $5.45

3M 29859, Sanding Screen, 100 grit, 12 in x 18 in, 7100160861

20 × $5.45 -

×

3M 07144, Inhalation Valve 6893/07144(AAD), System Component, 7000002049, 200 EA/Case

1 × $309.17

3M 07144, Inhalation Valve 6893/07144(AAD), System Component, 7000002049, 200 EA/Case

1 × $309.17 -

×

Standard Abrasives 873273, S/C Unitized Wheel, 732, 6 in x 1/4 in x 1/2 in, 7010301203

10 × $37.04

Standard Abrasives 873273, S/C Unitized Wheel, 732, 6 in x 1/4 in x 1/2 in, 7010301203

10 × $37.04 -

×

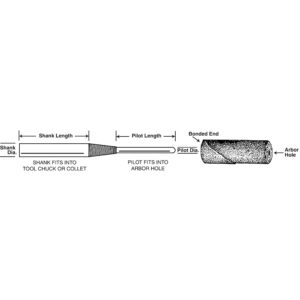

Standard Abrasives 701656, Cartridge RoII Mandrel, 3/16 in x 2 in x 1/4 in x 1-1/4 in x 4 in CM-18, 7010368730

5 × $5.56

Standard Abrasives 701656, Cartridge RoII Mandrel, 3/16 in x 2 in x 1/4 in x 1-1/4 in x 4 in CM-18, 7010368730

5 × $5.56 -

×

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97 -

×

Dynabrade 69522 Housing for 69500, 5,000 RPM

1 × $77.04

Dynabrade 69522 Housing for 69500, 5,000 RPM

1 × $77.04

3M 20276, Neoprene Contact Adhesive 10, Light Yellow, 5 Gallon Pour Spout Drum (Pail), 7000121218

$81.72

Factory Stock, 7-10 Day Leadtime

Available in tubes, cans or pails, 3M Neoprene Contact Adhesive 10 is a versatile, solvent based adhesive. It offers high immediate handling strength and good heat resistance, and is commonly used for bonding most metals and plastics. It is also suitable for large surface panel or composite lamination.