-

×

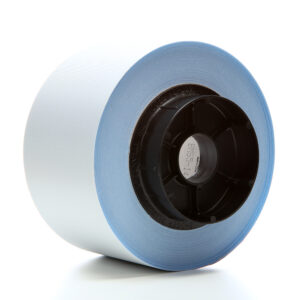

Norton 66254489957 Wheel, Vortex-7am, 6" X 1/2" X 1" C2312 Nor VTME7 PH VTC+, 4 Each

4 × $84.19

Norton 66254489957 Wheel, Vortex-7am, 6" X 1/2" X 1" C2312 Nor VTME7 PH VTC+, 4 Each

4 × $84.19 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76 -

×

Dynabrade 51702 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 3/32" Collet

1 × $558.00

Dynabrade 51702 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 3/32" Collet

1 × $558.00 -

×

Dynabrade 55501 .1hp Pencil Grinder, Twin Turbine, 100,000 RPM, Nickel-Plated Aluminum Housing, 3mm Collet

1 × $529.55

Dynabrade 55501 .1hp Pencil Grinder, Twin Turbine, 100,000 RPM, Nickel-Plated Aluminum Housing, 3mm Collet

1 × $529.55 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M 47191, Polyurethane Adhesive Sealant 550FC Fast Cure, White, 400 mL Sausage Pack, 7100197999, 12/Case

12 × $12.26

3M 47191, Polyurethane Adhesive Sealant 550FC Fast Cure, White, 400 mL Sausage Pack, 7100197999, 12/Case

12 × $12.26 -

×

Dynabrade 51624 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 35,000 RPM, 3mm Collet

1 × $603.00

Dynabrade 51624 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 35,000 RPM, 3mm Collet

1 × $603.00 -

×

Air Turbine Tools 310RDM - 1/4" Router Hand Tool Series, 40,000RPM, 33442

1 × $950.00

Air Turbine Tools 310RDM - 1/4" Router Hand Tool Series, 40,000RPM, 33442

1 × $950.00 -

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94 -

×

Insize 7232, SCRIBER, 6928640320088

1 × $7.01

Insize 7232, SCRIBER, 6928640320088

1 × $7.01 -

×

3M 96673, Glass Cloth Tape 398FR, White, 3 in x 36 yd, 7 mil, 7000001301

12 × $105.74

3M 96673, Glass Cloth Tape 398FR, White, 3 in x 36 yd, 7 mil, 7000001301

12 × $105.74 -

×

3M 25705, Scotch-Brite Roloc Surface Conditioning Disc, SC-DR, A/O Medium, TR, 3/4 in, 7000120983, 200/case

200 × $0.89

3M 25705, Scotch-Brite Roloc Surface Conditioning Disc, SC-DR, A/O Medium, TR, 3/4 in, 7000120983, 200/case

200 × $0.89 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58 -

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52 -

×

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

200 × $1.74

3M 76783, Cubitron II Hookit Cloth Disc 784F, 120+ XF-weight, 5 in x NH, Die 500X, 7100222757

200 × $1.74 -

×

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40 -

×

3M 26118, PPS Series 2.0 Adapter, Type S26, 11 mm Male, 1.0 mm Thread, 7100135924

4 × $25.96

3M 26118, PPS Series 2.0 Adapter, Type S26, 11 mm Male, 1.0 mm Thread, 7100135924

4 × $25.96 -

×

Dynabrade 51703 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 1/8" Collet

1 × $558.00

Dynabrade 51703 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 1/8" Collet

1 × $558.00 -

×

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

36 × $18.24

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

36 × $18.24 -

×

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

2 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

2 × $175.93 -

×

3M 26136, PPS Series 2.0 Adapter, Type S32, 18 mm Female, 1.5 mm

Thread, 7100135952

1 × $25.96

3M 26136, PPS Series 2.0 Adapter, Type S32, 18 mm Female, 1.5 mm

Thread, 7100135952

1 × $25.96 -

×

3M 35831, Hookit Dust Extraction Flexible Radius Sanding Block, 178 mm x 66 mm, 7100256512

24 × $45.74

3M 35831, Hookit Dust Extraction Flexible Radius Sanding Block, 178 mm x 66 mm, 7100256512

24 × $45.74 -

×

3M 16831, Urethane Seam Sealer, 08361, Gray, 310 mL Foil Pack, 7000120461, 6 per case

6 × $28.47

3M 16831, Urethane Seam Sealer, 08361, Gray, 310 mL Foil Pack, 7000120461, 6 per case

6 × $28.47 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 175u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 175u

12 × $7.60 -

×

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

1 × $502.78

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

1 × $502.78 -

×

Dynabrade 51705 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 3/32" Collet

1 × $558.00

Dynabrade 51705 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 3/32" Collet

1 × $558.00 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03 -

×

3M 62812, Adhesive Sealant 740 UV, White, 290 mL Cartridge, 7100116448, 12 per case

12 × $16.25

3M 62812, Adhesive Sealant 740 UV, White, 290 mL Cartridge, 7100116448, 12 per case

12 × $16.25

3M 08329, Controlled-Flow Seam Sealer, 200 mL Cartridge, 7000148203, 6 per case

$49.76

Factory Stock, 7-10 Day Leadtime

3M Controlled-Flow Seam Sealer offers considerable strength, flexes under torsional stress from vibration and withstands extreme weather. Our urethane formula contains no solvents and will not shrink or crack. These characteristics make it an ideal choice for automotive applications where motion and exposure to weather are a constant factor.

Tough, Flexible and Self-Leveling

3M™ Controlled-Flow Seam Sealer uses two-part urethane technology to provide a tough flexible material for the sealing of joints on primed or painted substrates such as steel or aluminum enclosures. 3M™ Control-Flow Seam Sealer works particularly well in areas where a flowable self-leveling type seam sealer is required. It is designed to flow one to two inches and then begins to cure, preventing further flow out of the material. This feature allows the user to control the application, preventing excessive waste while maintaining a uniform film thickness even on surfaces that are not level. Typical product uses include automotive “roof ditch” applications where a flow grade sealer is required and some “trunk rain gutter” seams where the use of a standard “self leveling” sealer is unacceptable due to flow characteristics.

Our urethane base auto body seam sealer has a paste consistency and is black/amber in color. This 3M seam sealer offers a 3 minute work time, cures in 2 hours and is ready for painting in about 40 minutes, depending on environmental conditions.

Directions for Use:

NOTE: 3M Best Practice is that all sealers, unless designated specifically for use on bare metal, be applied to properly prepared automotive paint or primer.

SURFACE PREPARATION:

NOTE: Apply only to surfaces primed with a 2K urethane, 2K epoxy primer, or clean, sanded paint. Acid etch primers should never be in direct contact with seam sealer.

- Scuff primed surface with a Scotch-Brite™ General Purpose Hand Pad (Ultrafine), (PN 07448).

- Blow off dust with clean, compressed air and wipe with a clean, dry rag.

PRODUCT PREPARATION:

- Insert cartridge into applicator gun.

- Remove retaining collar and plug from end of cartridge. Discard plug, save retaining collar.

- Extrude a small amount of product until both parts A and B dispense equally.

- Attach 3M™ Mixing Nozzle (PN 08193) to cartridge and lock in place with retaining collar.

- Dispense a small amount of material and discard.

GENERAL REPAIR PROCESS:

-

- Extrude sealer onto surface. Allow to cure a minimum of 40 minutes before beginning the painting process.

NOTE: If sealer is allowed to cure more than 24 hours, scuff the sealer prior to any painting steps.

3M Science Meets the Needs of Automotive Professionals

3M used the technical properties of two-part urethane to create a sealer that combines toughness with flexibility. This sealer is ideal for filling channels and drip rails on all types of vehicles and recreating puddle-type seams. It may also be used to seal water leaks in drip rails and channels.

Related products

Adhesives & Sealants

3M 08017, Marine Grade Silicone Sealant, White, 3 oz Tube, 7000120479, 6/Case

$15.76

Adhesives & Sealants

3M 08024, Adhesive Sealant 740 UV, Black, 290 mL Cartridge, 7100115542, 12 per case

$16.25

Adhesives & Sealants

3M 08365, Urethane Seam Sealer, Beige 310mL Cartridge, 7100024963, 12 per Case

$26.40

Adhesives & Sealants

3M 08364, Urethane Seam Sealer, Beige, 310 mL Foil Pack, 7100049259, 6 per case

$28.47