-

×

Dynabrade 56323 3-7/8" x 5-5/8" Vacuum Dynabug II Disc Pad, Hook-Face, Short Nap

1 × $33.47

Dynabrade 56323 3-7/8" x 5-5/8" Vacuum Dynabug II Disc Pad, Hook-Face, Short Nap

1 × $33.47 -

×

Dynabrade X51 5" (127 mm) Dia. Non-Vacuum Dynorbital Extreme Random Orbital Sander, .3 HP, 12,000 RPM, 3/16" Orbit, PSA

1 × $213.35

Dynabrade X51 5" (127 mm) Dia. Non-Vacuum Dynorbital Extreme Random Orbital Sander, .3 HP, 12,000 RPM, 3/16" Orbit, PSA

1 × $213.35 -

×

Dynabrade 51466 Housing for Model 53080

1 × $478.99

Dynabrade 51466 Housing for Model 53080

1 × $478.99 -

×

Dynabrade 57955 - 2-7/8" (73 mm) W x 3-1/8" (79 mm) L Non-Vacuum Dynafine Triangular Disc Pad, Hook-Face, Long Nap

1 × $29.40

Dynabrade 57955 - 2-7/8" (73 mm) W x 3-1/8" (79 mm) L Non-Vacuum Dynafine Triangular Disc Pad, Hook-Face, Long Nap

1 × $29.40 -

×

Dynabrade 51046 Pin

1 × $2.17

Dynabrade 51046 Pin

1 × $2.17 -

×

Dynabrade 51134 Dynastraight Flapper 8" (203 mm) Extension Finishing Tool, 18,000 RPM, 1/4"20 Female Thread

1 × $830.05

Dynabrade 51134 Dynastraight Flapper 8" (203 mm) Extension Finishing Tool, 18,000 RPM, 1/4"20 Female Thread

1 × $830.05 -

×

Dynabrade 55653 3Hp Rotor

1 × $188.90

Dynabrade 55653 3Hp Rotor

1 × $188.90 -

×

Dynabrade 55027 Rear End Plate

1 × $68.08

Dynabrade 55027 Rear End Plate

1 × $68.08 -

×

Dynabrade 60210 - 9,000 lb. Jack with 3/4" Vi-Sorb Pad

1 × $261.65

Dynabrade 60210 - 9,000 lb. Jack with 3/4" Vi-Sorb Pad

1 × $261.65 -

×

Dynabrade 54950 Spindle, W/Balancer, Type 27

1 × $110.25

Dynabrade 54950 Spindle, W/Balancer, Type 27

1 × $110.25 -

×

Dynabrade 18599 Spindle, M-14

1 × $77.73

Dynabrade 18599 Spindle, M-14

1 × $77.73 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

Dynabrade 18718 Ball Bearing

1 × $19.57

Dynabrade 18718 Ball Bearing

1 × $19.57 -

×

Dynabrade 78730 1" x 1/8"-W215 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $4.55

Dynabrade 78730 1" x 1/8"-W215 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $4.55 -

×

Dynabrade 98630 Shaft Seal

1 × $11.55

Dynabrade 98630 Shaft Seal

1 × $11.55 -

×

Dynabrade 18773 Cam Release Spring

1 × $5.18

Dynabrade 18773 Cam Release Spring

1 × $5.18 -

×

Dynabrade 54914 Gear, 30 Tooth, 6,500 RPM

1 × $417.36

Dynabrade 54914 Gear, 30 Tooth, 6,500 RPM

1 × $417.36 -

×

Dynabrade 54931 Auto Balancer (Sander)

1 × $165.42

Dynabrade 54931 Auto Balancer (Sander)

1 × $165.42 -

×

Dynabrade 57766 - 6" (152 mm) Dia. Channel Vacuum Gear-Driven Disc Pad, Hook-Face, Short Nap

1 × $37.95

Dynabrade 57766 - 6" (152 mm) Dia. Channel Vacuum Gear-Driven Disc Pad, Hook-Face, Short Nap

1 × $37.95 -

×

Dynabrade 57792 - 5" (127 mm) Dia. Non-Vacuum Disc Pad, Hook-Face, Medium Nap

1 × $41.65

Dynabrade 57792 - 5" (127 mm) Dia. Non-Vacuum Disc Pad, Hook-Face, Medium Nap

1 × $41.65 -

×

Dynabrade 21443 ND1032, Top Bearing Seal

1 × $6.41

Dynabrade 21443 ND1032, Top Bearing Seal

1 × $6.41 -

×

Dynabrade 18749 Spanner Wrench

1 × $6.03

Dynabrade 18749 Spanner Wrench

1 × $6.03 -

×

Dynabrade 11092 Contact Wheel, 3/8" Wide x 1" Dia., Radius, 40 Durometer Neoprene

1 × $26.95

Dynabrade 11092 Contact Wheel, 3/8" Wide x 1" Dia., Radius, 40 Durometer Neoprene

1 × $26.95 -

×

Dynabrade 51139 Housing for Model 51134, 18,000 RPM

1 × $119.94

Dynabrade 51139 Housing for Model 51134, 18,000 RPM

1 × $119.94 -

×

Dynabrade 57988 - Inlet Hose Assembly

1 × $13.09

Dynabrade 57988 - Inlet Hose Assembly

1 × $13.09 -

×

Dynabrade 53251 7" Dia. Vertical Disc Sander

1 × $1,407.32

Dynabrade 53251 7" Dia. Vertical Disc Sander

1 × $1,407.32 -

×

Dynabrade 50767 Spring Pin

1 × $1.93

Dynabrade 50767 Spring Pin

1 × $1.93 -

×

Dynabrade 51296 Housing for Model 52325

1 × $102.11

Dynabrade 51296 Housing for Model 52325

1 × $102.11 -

×

Dynabrade 56107 6" Dia. Non-Vacuum Disc Pad, Vinyl-Face

1 × $27.37

Dynabrade 56107 6" Dia. Non-Vacuum Disc Pad, Vinyl-Face

1 × $27.37 -

×

Dynabrade 94605 Pin Wrench, Assembly, Turbine Pencil Grinder

1 × $162.10

Dynabrade 94605 Pin Wrench, Assembly, Turbine Pencil Grinder

1 × $162.10 -

×

Dynabrade 59339 Vacuum Cuff, 1", w/Groove

1 × $12.63

Dynabrade 59339 Vacuum Cuff, 1", w/Groove

1 × $12.63 -

×

Dynabrade 92187 1" W x 30" L 80 Grit A/Z DynaCut Belt, 50/pack

50 × $3.54

Dynabrade 92187 1" W x 30" L 80 Grit A/Z DynaCut Belt, 50/pack

50 × $3.54 -

×

Dynabrade 79173 2" W x 30" L 60 Grit Ceramic DynaCut Belt, 10/pack

10 × $15.91

Dynabrade 79173 2" W x 30" L 60 Grit Ceramic DynaCut Belt, 10/pack

10 × $15.91 -

×

Dynabrade 78318 2" Dia. x 1" W x 1/4" Shank, Very Fine, NWN DynaBrite Wheel, 10/pack

10 × $12.50

Dynabrade 78318 2" Dia. x 1" W x 1/4" Shank, Very Fine, NWN DynaBrite Wheel, 10/pack

10 × $12.50 -

×

Dynabrade 68000 Coolant Filtration System, 115 V (AC), 1 Phase, 60 Hz

3 × $3,859.84

Dynabrade 68000 Coolant Filtration System, 115 V (AC), 1 Phase, 60 Hz

3 × $3,859.84 -

×

Dynabrade 79151 1" W x 24" L 60 Grit DynaCut Premium Ceramic Belt, 50/pack

50 × $4.74

Dynabrade 79151 1" W x 24" L 60 Grit DynaCut Premium Ceramic Belt, 50/pack

50 × $4.74 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89 -

×

Dynabrade 11280 Contact Arm Ass'y, 1" Da. x 3/8" W, Tapered Rubber Wheel, No Platen/Offset Design

1 × $99.36

Dynabrade 11280 Contact Arm Ass'y, 1" Da. x 3/8" W, Tapered Rubber Wheel, No Platen/Offset Design

1 × $99.36 -

×

Dynabrade 95676 1/4" Female Coupler with 1/4" Male Plug Assembly

1 × $29.99

Dynabrade 95676 1/4" Female Coupler with 1/4" Male Plug Assembly

1 × $29.99 -

×

Dynabrade 79108 1/2" W x 12" L 60 Grit DynaCut Premium Ceramic Belts, 50/pack

50 × $2.45

Dynabrade 79108 1/2" W x 12" L 60 Grit DynaCut Premium Ceramic Belts, 50/pack

50 × $2.45 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

Dynabrade 11218 Contact Arm Ass'y, 5/8" Dia. x 3/8" W, Rubber Wheel, with 1/2" W Platen

1 × $69.58

Dynabrade 11218 Contact Arm Ass'y, 5/8" Dia. x 3/8" W, Rubber Wheel, with 1/2" W Platen

1 × $69.58 -

×

Dynabrade 64002 SuperFinisher, 230 Volts (AC), 1 Phase, 50 Hz

3 × $14,467.64

Dynabrade 64002 SuperFinisher, 230 Volts (AC), 1 Phase, 50 Hz

3 × $14,467.64

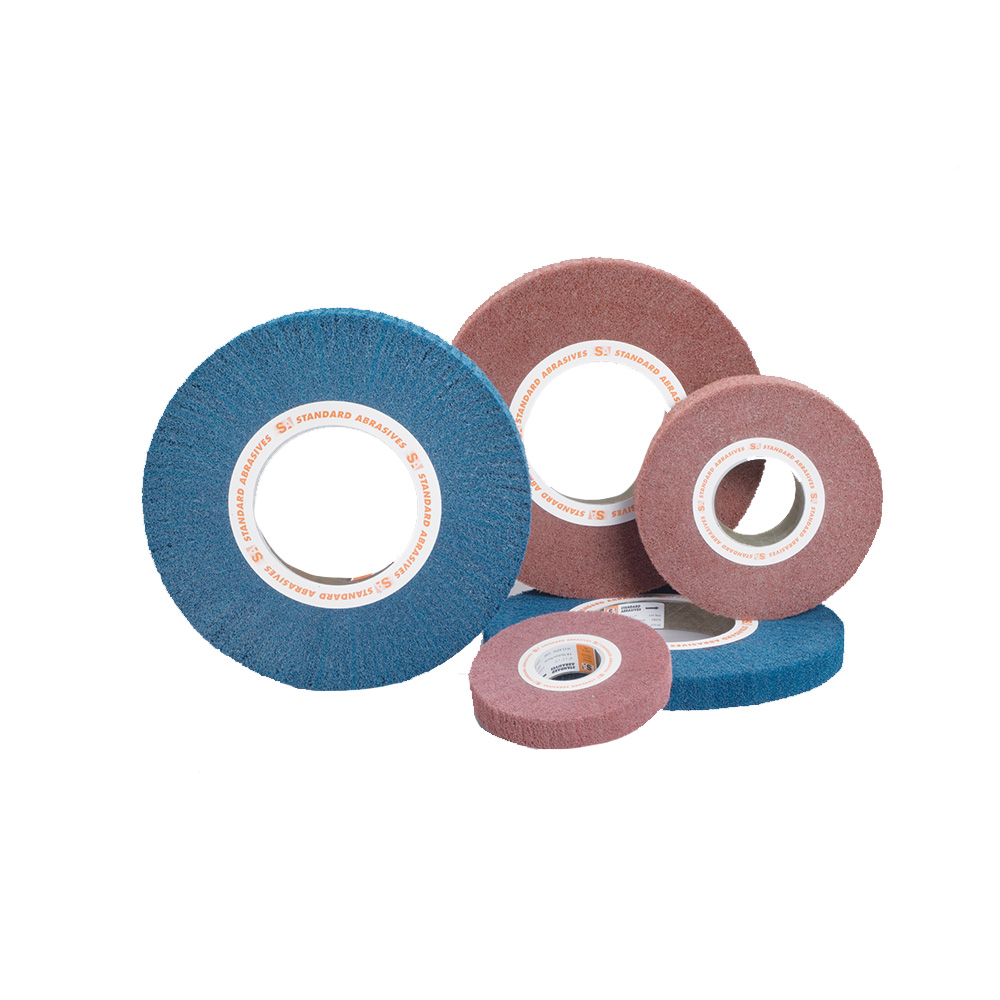

Standard Abrasives 875002, Buff and Blend Flap Brush, 8 in x 1 in x 3 in FB099 15-87 A VFN Medium Density, 7010310137

$75.77

Factory Stock, 7-10 Day Leadtime

The conformability and consistent performance of our Standard Abrasives Buff and Blend Flap Brush makes it ideal for blending, cleaning, deburring and finishing on stainless steel, brass and aluminum, especially where a uniform and long line brushed finish is desired.

Quality Materials and Construction for Demanding Finishing Applications

Standard Abrasives™ Buff and Blend products are made from tough, resin-reinforced nylon fiber with aluminum oxide abrasive grain. The durable high strength construction of our Standard Abrasives™ Buff and Blend Flap Brush provides aggressive, controlled action and a consistent, uniform finish without leaving behind parting lines. Non-woven construction conforms to workpiece contours, curves, and ridges and allows removing surface contaminants without eliminating critical detail or gouging the workpiece. Choose from a broad offering of sizes, densities and grades to suit many different finishing operations.

A Buff and Blend Flap Brush is an ideal choice for:

- A grain finish on brass strike plates for door hardware

- A satin finish on builders’ hardware (cabinet handles, door knobs, and more)

- Satin finishes on soft metals

- Inline brushed finishes on aluminum and stainless cookware (pots and pans)

- Producing fine scratch patterns on utensils and cutlery prior to cotton buff and compound polishing

- Removing oxide from precious metals

- Blending flash and parting lines on aluminum die cast

Featuring Consistent Finishes and Operator Comfort

Flap brushes produce a consistent finish which does not reflect lines commonly attributed with ganged arbor hole discs. Density, pressure and angle determine the ability of the flap brush to remove burrs, oxidation and handling marks. The abrasive material provides ventilation which helps dissipate heat and, therefore, runs cooler. This provides consistent finishes without smearing or otherwise discoloring the work piece. Minimal vibration can reduce chattermarks on the workpiece and can lead to less operator and machine fatigue.

Load-Resistant Construction Boosts Life and Performance

Standard Abrasives™ Buff and Blend products are load-resistant to keep you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape. Consequently, less debris clogs the abrasive, so the mineral can stay fresh, keep cutting sharp and deliver a consistent cut over the life of the product. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

The Many Benefits of Standard Abrasives™ Buff and Blend Products

Standard Abrasives™ Buff and Blend products invigorate deburring, cleaning, blending and finishing applications by helping operators reduce finishing steps, minimize costs and achieve greater throughput. Each Buff and Blend product and grade offers unique benefits, so operators can choose from a versatile range of options to ensure superior performance on specific applications.