-

×

3M 28830, 675L, 1/2" X 72", 74u, Diamond Microfinishing Film Belt 7010508919

6 × $29.15

3M 28830, 675L, 1/2" X 72", 74u, Diamond Microfinishing Film Belt 7010508919

6 × $29.15 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 175u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 175u

12 × $7.60 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

Dynabrade 92150 1/2" W x 18" L 80 Grit Ceramic DynaCut Scalloped Edge Belt, 50/pack

50 × $4.35

Dynabrade 92150 1/2" W x 18" L 80 Grit Ceramic DynaCut Scalloped Edge Belt, 50/pack

50 × $4.35 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 250u

12 × $8.20

ACS CX1250 Diamond Belt, 1/2" X 24" 250u

12 × $8.20 -

×

Dynabrade 78594 3/8" Dia. x 1-1/2" W x 1/8" Center Hole, 60 Grit, 100/pack

100 × $50.00

Dynabrade 78594 3/8" Dia. x 1-1/2" W x 1/8" Center Hole, 60 Grit, 100/pack

100 × $50.00 -

×

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50

3M 22393, Roloc Disc 361F, 36 YF-weight, TR, 3 in, Die R300V, 7000045093

200 × $1.50 -

×

3M 05777, Hookit Soft Interface Pad, 6 x 1/2 x 3/4 inch, 7000028239

10 × $20.46

3M 05777, Hookit Soft Interface Pad, 6 x 1/2 x 3/4 inch, 7000028239

10 × $20.46 -

×

3M 30688, Cloth Belt 577F, 120 YF-weight, 3/4 in x 18 in, Fabri-lok, Single-flex, 7000119460, 200 per case

200 × $1.61

3M 30688, Cloth Belt 577F, 120 YF-weight, 3/4 in x 18 in, Fabri-lok, Single-flex, 7000119460, 200 per case

200 × $1.61 -

×

Dynabrade 93095 3" Dia. x 80 Grit Premium Ceramic Non-Vacuum DynaCut, Locking-Type Disc, 3 Ply Cloth, 25/pack

25 × $2.09

Dynabrade 93095 3" Dia. x 80 Grit Premium Ceramic Non-Vacuum DynaCut, Locking-Type Disc, 3 Ply Cloth, 25/pack

25 × $2.09 -

×

3M 34552, Cubitron II Net Sheet Roll, 150+, 80 mm x 10 m, 7100247337, 6 Rolls/Case

6 × $28.94

3M 34552, Cubitron II Net Sheet Roll, 150+, 80 mm x 10 m, 7100247337, 6 Rolls/Case

6 × $28.94 -

×

Dynabrade X61 6" (152 mm) Dia. Non-Vacuum Dynorbital Extreme Random Orbital Sander, .3 HP, 12,000 RPM, 3/16" Orbit, PSA

1 × $213.35

Dynabrade X61 6" (152 mm) Dia. Non-Vacuum Dynorbital Extreme Random Orbital Sander, .3 HP, 12,000 RPM, 3/16" Orbit, PSA

1 × $213.35 -

×

3M 30697, Cloth Belt 577F, 120 YF-weight, 2 in x 72 in, Film-lok, Single-flex, 7010300158, 50 per case

50 × $7.09

3M 30697, Cloth Belt 577F, 120 YF-weight, 2 in x 72 in, Film-lok, Single-flex, 7010300158, 50 per case

50 × $7.09 -

×

ACS Diamond Cloth Belt, CX1250 1/2" X 72" 125U

12 × $23.20

ACS Diamond Cloth Belt, CX1250 1/2" X 72" 125U

12 × $23.20 -

×

3M 53036, 663FC, 1/2" X 90", 20u, Diamond Trizact Belt 7100205970

1 × $0.00

3M 53036, 663FC, 1/2" X 90", 20u, Diamond Trizact Belt 7100205970

1 × $0.00 -

×

Dynabrade 78585 1/4" Dia. x 1-1/2" W x 1/8" Center Hole, 120 Grit, 100/pack

100 × $44.00

Dynabrade 78585 1/4" Dia. x 1-1/2" W x 1/8" Center Hole, 120 Grit, 100/pack

100 × $44.00 -

×

Dynabrade 78126 3" Dia., Fine, NWN DynaBrite, TR Locking-Type Disc, 25/pack

25 × $3.64

Dynabrade 78126 3" Dia., Fine, NWN DynaBrite, TR Locking-Type Disc, 25/pack

25 × $3.64 -

×

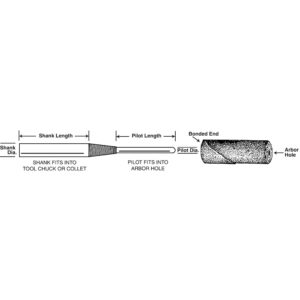

Standard Abrasives 710190, Cartridge Roll Mandrel, 2560020, 1/8 in x 1 in x 1/4 in x 1-1/4 in x 2-3/4 in CM-9, 7000121790

5 × $4.17

Standard Abrasives 710190, Cartridge Roll Mandrel, 2560020, 1/8 in x 1 in x 1/4 in x 1-1/4 in x 2-3/4 in CM-9, 7000121790

5 × $4.17 -

×

3M 34572, Cubitron II Net Sheet Roll 80+, 115 mm x 10 m, 7100247508, 6 Rolls/Case

6 × $42.69

3M 34572, Cubitron II Net Sheet Roll 80+, 115 mm x 10 m, 7100247508, 6 Rolls/Case

6 × $42.69 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.93

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.93

Standard Abrasives 856192, Multi-Finish Wheel, 6 in x 1 in x 1 in 2S MED, 7000122096

$48.67

Factory Stock, 7-10 Day Leadtime

Standard Abrasives Multi-Finish Wheel is a low density, durable wheel used primarily for applications requiring a linear scratch and final finish on surfaces where no edges or burrs are present.

Low Density, High Performance

We purposefully engineered our Standard Abrasives™ Multi-Finish Wheel as a low density wheel, so it would conform to the workpiece and leave a soft scratch pattern without greatly altering the geometry of the part. During final finishing with a low density wheel like our Standard Abrasives™ Multi-Finish Wheel, low pressure should be applied. This helps prevent gouging or denting of the surface and, as an added benefit, reduces operator fatigue. Moreover, because the wheel is low density, it splays out a bit more than a hard density wheel would, allowing greater contact with the workpiece surface area.

Soft Scratch Patterns

The Standard Abrasives™ Multi-Finish Wheel is designed by mixing silicon carbide mineral and nonwoven nylon fibers with resin to create an open web. Although it dulls more quickly, silicon carbide is harder and sharper than most aluminum oxides. Combining sharp cutting mineral with low pressure makes for a good, soft scratch pattern that users desire during final finishing. The mineral comes in fine (FIN), medium (MED) and coarse (CRS) grades. Users should opt for a fine grade for the softest scratch pattern and a coarser grade for a rougher scratch pattern.

Benefits of Open Web Abrasives

Nonwoven fibers in open web break down during grinding to reveal new mineral, and the benefits are twofold. First, mineral renewal lends itself to a consistent scratch pattern, applied evenly throughout the life of the abrasive. Second, even attrition, or uniform breakdown of the fibers, prevents chunking or dusting. Because they are non-metallic, the nylon fibers do not contaminate metal; they won’t melt or produce the heat-induced smears and blemishes that might result from metal on metal.

Combining buoyant, responsive nonwoven fibers with sharp-cutting silicon carbide mineral make this abrasive a great match for final finishing. It performs well when blending coated abrasive scratches or blending surfaces to match a #4 mil finish. Some other great applications include satin finishing on architectural hardware or grain finishes prior to anodizing.

Whether stainless steel fabricators or appliance and food equipment manufacturers, our multi-finishing wheel is designed to help users from multiple industries achieve the final finish they desire. From door hardware, to plumbing fixtures, aluminum extrusions, sanitary metal containers and dairy equipment, this wheel is a good abrasive product for final finishing on a range of workpieces.

Related products

Unitized/ Deburring Wheels

$18.43

Multi-Finishing Wheels

3M 13180, Scotch-Brite Multi-Finishing Wheel, MU-WL, 2S Medium, 6 in x 3 in x 1 in, 7000148248

$133.38