-

×

3M 45708, Cubitron II Hookit Cloth Disc 947A, 60+ X-weight, 6 in x NH, Die 600Z, 7100113142

200 × $3.25

3M 45708, Cubitron II Hookit Cloth Disc 947A, 60+ X-weight, 6 in x NH, Die 600Z, 7100113142

200 × $3.25 -

×

3M 00705, Interam Stainless Steel Foil Tape T-65, 4 in x 100 ft, 7100024280

72 × $192.19

3M 00705, Interam Stainless Steel Foil Tape T-65, 4 in x 100 ft, 7100024280

72 × $192.19 -

×

Dynabrade 77770 5" Dia. x 7/8" Center Holes, 120 Grit, Z/A, Type 27, DynaCut Flap Disc w/Fiberglass, 10/pack

10 × $5.43

Dynabrade 77770 5" Dia. x 7/8" Center Holes, 120 Grit, Z/A, Type 27, DynaCut Flap Disc w/Fiberglass, 10/pack

10 × $5.43 -

×

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

Dynabrade 78380 3" Dia. x 1/2", Dyna Premium Rapid Strip TR Disc, 25/pack

25 × $9.79

Dynabrade 78380 3" Dia. x 1/2", Dyna Premium Rapid Strip TR Disc, 25/pack

25 × $9.79

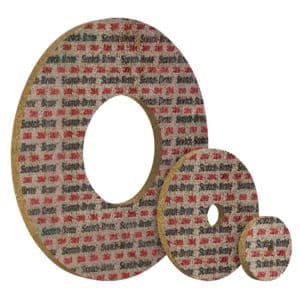

Standard Abrasives 852333, LDW Wheel, 8 in x 1 in x 3 in 7S FIN, 7000046893

$115.47

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.