-

×

3M 36879, Self-Stick Liquid Protection Fabric, Blue, 28 in x 300 ft, 7100169496

1 × $623.42

3M 36879, Self-Stick Liquid Protection Fabric, Blue, 28 in x 300 ft, 7100169496

1 × $623.42 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M 05783, Hookit Pad D/F, 8 in x 5 bolt hole, 7000119884

1 × $76.81

3M 05783, Hookit Pad D/F, 8 in x 5 bolt hole, 7000119884

1 × $76.81 -

×

3M 34786, 663FC, 3/4" X 90", 70u, Diamond Trizact Belts 7100063667

1 × $300.00

3M 34786, 663FC, 3/4" X 90", 70u, Diamond Trizact Belts 7100063667

1 × $300.00 -

×

3M 15938 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 1-1/2 in x 60 in, 7010300824

10 × $28.08

3M 15938 Scotch-Brite Surface Conditioning Low Stretch Belt, SC-BL, A/O Medium, 1-1/2 in x 60 in, 7010300824

10 × $28.08

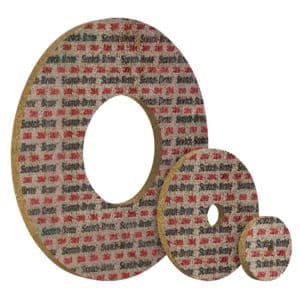

3M 01319, Scotch-Brite Cut and Polish Flap Brush, 12 in x 2 in x 5 in 7A MED, 7010299326

$318.49

Factory Stock, 7-10 Day Leadtime

Scotch-Brite Cut and Polish Flap Brushes are a versatile, high-performance alternative to conventional bristle brushes and messy, technique-dependent buffing compounds. These long-lasting, precision-made brushes give you improved consistency and greater control over a number of critical metal prep and finishing tasks, including cleaning, deburring, polishing, and aesthetic finishing.