-

×

Insize 3101-100E, DIGITAL OUTSIDE MICROMETER, IP65, 3-4"/75-100mm, 6928640326813

1 × $311.93

Insize 3101-100E, DIGITAL OUTSIDE MICROMETER, IP65, 3-4"/75-100mm, 6928640326813

1 × $311.93 -

×

3M 16582, Accuspray Atomizing Head, Blue, 1.2 mm, 7010363219

10 × $10.67

3M 16582, Accuspray Atomizing Head, Blue, 1.2 mm, 7010363219

10 × $10.67 -

×

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series, 25,000RPM, 33421

1 × $950.00

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series, 25,000RPM, 33421

1 × $950.00 -

×

Insize 6300, MICROMETER STAND, 6928640307294

1 × $51.04

Insize 6300, MICROMETER STAND, 6928640307294

1 × $51.04 -

×

3M 62820, Adhesive Sealant 760 UV, Gray, 600 mL Sausage Pack, 7000046611, 12/Case

12 × $26.69

3M 62820, Adhesive Sealant 760 UV, Gray, 600 mL Sausage Pack, 7000046611, 12/Case

12 × $26.69 -

×

Dynabrade 78425 4-1/2" Dia. x 3/8" Coarse DynaBrite Surface Conditioning Disc, 25/pack

25 × $6.23

Dynabrade 78425 4-1/2" Dia. x 3/8" Coarse DynaBrite Surface Conditioning Disc, 25/pack

25 × $6.23 -

×

Dynabrade 51862 .4 hp Trim Router (Complete), 30,000 RPM, 1/4 Collet

1 × $680.48

Dynabrade 51862 .4 hp Trim Router (Complete), 30,000 RPM, 1/4 Collet

1 × $680.48 -

×

3M 82511, Steel Mesh Faceshield Screen W96MW 82511-00000, with Clear Eyeshield, Headgear Not Included 10 EA/Case, 7000127231

2 × $701.18

3M 82511, Steel Mesh Faceshield Screen W96MW 82511-00000, with Clear Eyeshield, Headgear Not Included 10 EA/Case, 7000127231

2 × $701.18 -

×

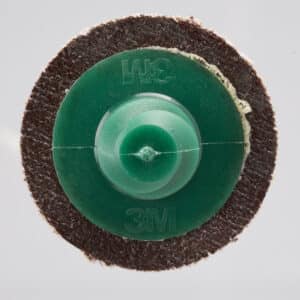

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39

3M 22394, Roloc Disc 361F, 50 YF-weight, TR, 3 in, Die R300V, 7000045096

200 × $1.39 -

×

3M 28848, Unitized Wheel Mandrel 28848, 1-5/8 in x 1/4 in x 3/4 in x 1/4 in, 7100082547

5 × $18.31

3M 28848, Unitized Wheel Mandrel 28848, 1-5/8 in x 1/4 in x 3/4 in x 1/4 in, 7100082547

5 × $18.31 -

×

3M 10118, Synthetic Steel Wool Pads, 10118NA, #0 Fine, 7000126148

18 × $2.69

3M 10118, Synthetic Steel Wool Pads, 10118NA, #0 Fine, 7000126148

18 × $2.69 -

×

3M 64324, Foil Tape 3340, Silver, 72 mm x 45.7 m, 3.9 mil, 7010335734

32 × $33.04

3M 64324, Foil Tape 3340, Silver, 72 mm x 45.7 m, 3.9 mil, 7010335734

32 × $33.04 -

×

Insize 6144, ACCESSORY SET FOR DIGITAL CALIPERS, 6928640380839

2 × $83.88

Insize 6144, ACCESSORY SET FOR DIGITAL CALIPERS, 6928640380839

2 × $83.88 -

×

Dynabrade 02084 Angle Housing Assembly,Steel, Rear Exhaust

1 × $220.09

Dynabrade 02084 Angle Housing Assembly,Steel, Rear Exhaust

1 × $220.09 -

×

3M 76631, Roloc Disc 777F, TR, 3 in x NH, 36 YF-weight, 7000028339

200 × $1.61

3M 76631, Roloc Disc 777F, TR, 3 in x NH, 36 YF-weight, 7000028339

200 × $1.61 -

×

Dynabrade 51812 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 3/32" Collet

1 × $715.47

Dynabrade 51812 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 1000,000 RPM, 3/32" Collet

1 × $715.47 -

×

Dynabrade 60051 .1 hp Straight-Line Quick-Change Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $976.11

Dynabrade 60051 .1 hp Straight-Line Quick-Change Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $976.11 -

×

Insize 7231, SCRIBER, 6928640320071

1 × $6.59

Insize 7231, SCRIBER, 6928640320071

1 × $6.59 -

×

Standard Abrasives 704214, A/O Full Taper Cartridge Roll, 3/8 in x 1-1/2 in x 1/8 in 60, 7100085864

100 × $0.76

Standard Abrasives 704214, A/O Full Taper Cartridge Roll, 3/8 in x 1-1/2 in x 1/8 in 60, 7100085864

100 × $0.76 -

×

Insize 1136-451WL, WIRELESS DIGITAL CALIPER (jaw length 100mm), 0-450mm/0-18", 0.01mm/0.0005", 6940561960815

1 × $741.70

Insize 1136-451WL, WIRELESS DIGITAL CALIPER (jaw length 100mm), 0-450mm/0-18", 0.01mm/0.0005", 6940561960815

1 × $741.70 -

×

Insize 1120-150A, ELECTRONIC INSIDE GROOVE CALIPER, 22-150mm, 6928640302220

1 × $160.30

Insize 1120-150A, ELECTRONIC INSIDE GROOVE CALIPER, 22-150mm, 6928640302220

1 × $160.30 -

×

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

108 × $18.24

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

108 × $18.24 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $10.89 -

×

3M 22399, Roloc Disc 361F, 50 YF-weight, TR, 2 in, Die R200P, 7000028184

200 × $1.11

3M 22399, Roloc Disc 361F, 50 YF-weight, TR, 2 in, Die R200P, 7000028184

200 × $1.11 -

×

3M 26120, PPS Series 2.0 Adapter, Type S28, 17.5 mm Female, 19 TPI

Thread, 7100135956

3 × $25.96

3M 26120, PPS Series 2.0 Adapter, Type S28, 17.5 mm Female, 19 TPI

Thread, 7100135956

3 × $25.96 -

×

Insize 7232, SCRIBER, 6928640320088

1 × $7.01

Insize 7232, SCRIBER, 6928640320088

1 × $7.01 -

×

3M 26016, PPS Series 2.0 Adapter, Type S9, 16 mm Male, 1.5 mm Thread, 7100135330

4 × $25.96

3M 26016, PPS Series 2.0 Adapter, Type S9, 16 mm Male, 1.5 mm Thread, 7100135330

4 × $25.96 -

×

3M 87669, Diamond Grade DG3 Reflective Sheeting 4090DS White for Digital Printing, 36 in x 50 yd, 7100116464

1 × $2,355.35

3M 87669, Diamond Grade DG3 Reflective Sheeting 4090DS White for Digital Printing, 36 in x 50 yd, 7100116464

1 × $2,355.35 -

×

Insize 6318, CALIPER/MICROMETER GRINDING MACHINE (caliper grinding blocks are included), 6940561953862

1 × $3,744.91

Insize 6318, CALIPER/MICROMETER GRINDING MACHINE (caliper grinding blocks are included), 6940561953862

1 × $3,744.91 -

×

3M 27551, EMI Copper Foil Shielding Tape 1181, 1/2 in x 18 yd (12.70 mm x 16.5m), 7000132182

18 × $39.89

3M 27551, EMI Copper Foil Shielding Tape 1181, 1/2 in x 18 yd (12.70 mm x 16.5m), 7000132182

18 × $39.89 -

×

3M 76374, Hot Melt Adhesive 3748 Q, Off-White, 5/8 in x 8 in, 7000000878, 11 LBS/Case

11 × $36.97

3M 76374, Hot Melt Adhesive 3748 Q, Off-White, 5/8 in x 8 in, 7000000878, 11 LBS/Case

11 × $36.97 -

×

3M 15041, Scotch Electrical Shielding Tape 24, 1 in x 15 ft (25 mm x 4,6 m), 7000031348

10 × $38.32

3M 15041, Scotch Electrical Shielding Tape 24, 1 in x 15 ft (25 mm x 4,6 m), 7000031348

10 × $38.32 -

×

3M 82561, Hot Melt Adhesive 3747 Q, Tan, 5/8 in x 8 in, 7000000877, 11 LBS/Case

11 × $28.33

3M 82561, Hot Melt Adhesive 3747 Q, Tan, 5/8 in x 8 in, 7000000877, 11 LBS/Case

11 × $28.33 -

×

Insize 0010-A35, SOUND LEVEL METER, 35dB~130dB, 6974029777004

1 × $170.80

Insize 0010-A35, SOUND LEVEL METER, 35dB~130dB, 6974029777004

1 × $170.80 -

×

3M 26119, PPS Series 2.0 Adapter, Type S27, 16 mm Male, 1.5 mm Thread, 7100135925

4 × $25.96

3M 26119, PPS Series 2.0 Adapter, Type S27, 16 mm Male, 1.5 mm Thread, 7100135925

4 × $25.96 -

×

3M 20921, PSA Cloth Disc 348D, 80 X-weight, 1-1/2 in x NH, Die 150S, 7010299967

1000 × $0.48

3M 20921, PSA Cloth Disc 348D, 80 X-weight, 1-1/2 in x NH, Die 150S, 7010299967

1000 × $0.48 -

×

3M 76790, Roloc Disc 361F, 60 YF-weight, TS, 2 in, Die RS200P, 7010300088

200 × $1.13

3M 76790, Roloc Disc 361F, 60 YF-weight, TS, 2 in, Die RS200P, 7010300088

200 × $1.13 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00 -

×

3M 11000, Roloc Disc 361F, 24 YF-weight, TR, 2 in, Die R200P, 7000028183

200 × $1.25

3M 11000, Roloc Disc 361F, 24 YF-weight, TR, 2 in, Die R200P, 7000028183

200 × $1.25 -

×

3M 76630, Roloc Disc 777F, 50 YF-weight, TR, 2 in, Die R200P, 7000045627

200 × $1.18

3M 76630, Roloc Disc 777F, 50 YF-weight, TR, 2 in, Die R200P, 7000045627

200 × $1.18 -

×

3M 26130, PPS Series 2.0 Adapter, Type S35, 16 mm Female, 1.5 mm

Thread Stretched, 7100135926

1 × $25.96

3M 26130, PPS Series 2.0 Adapter, Type S35, 16 mm Female, 1.5 mm

Thread Stretched, 7100135926

1 × $25.96 -

×

Insize 3293-061, CAN SEAM MICROMETER, 0-.5", for steel cans, 6928640328497

1 × $140.37

Insize 3293-061, CAN SEAM MICROMETER, 0-.5", for steel cans, 6928640328497

1 × $140.37 -

×

Dynabrade 52861 .4 hp Straight-Line Pencil Grinder, Rear Exhaust, 25,000 RPM, 1/8" Collet

1 × $555.41

Dynabrade 52861 .4 hp Straight-Line Pencil Grinder, Rear Exhaust, 25,000 RPM, 1/8" Collet

1 × $555.41 -

×

3M 66165, Wind Protection Tape Edge Sealer W2600, 50 ml (1.7 fluid ounce), 7100008766, 12/Case

12 × $69.98

3M 66165, Wind Protection Tape Edge Sealer W2600, 50 ml (1.7 fluid ounce), 7100008766, 12/Case

12 × $69.98 -

×

3M 50010, VentureClad Insulation Jacketing Tape 1577CW-WME, White, 99 mm x 13.7 m, 7010379907

12 × $44.16

3M 50010, VentureClad Insulation Jacketing Tape 1577CW-WME, White, 99 mm x 13.7 m, 7010379907

12 × $44.16 -

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $27,619.39

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $27,619.39 -

×

Insize 0213-A500, INFRARED THERMOMETER, -58?F~716?F/-50?C~380?C, 6940561934700

1 × $79.29

Insize 0213-A500, INFRARED THERMOMETER, -58?F~716?F/-50?C~380?C, 6940561934700

1 × $79.29 -

×

3M 87670, High Intensity Prismatic Reflective Sheeting 3930DS White forDigital Printing, 24 in x 50 yd, 7100116165

1 × $641.72

3M 87670, High Intensity Prismatic Reflective Sheeting 3930DS White forDigital Printing, 24 in x 50 yd, 7100116165

1 × $641.72 -

×

Insize 4120-20, METRIC THREAD RING GAGE, GO, M20x2.5, 6928640341519

1 × $71.83

Insize 4120-20, METRIC THREAD RING GAGE, GO, M20x2.5, 6928640341519

1 × $71.83 -

×

Dynabrade 51629 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 1/8" Collet

2 × $573.77

Dynabrade 51629 .1 hp Straight-Line Pencil Grinder, Central Vacuum, 1/8" Collet

2 × $573.77 -

×

Insize 4120-11, METRIC THREAD RING GAGE, GO, M11x1.5, 6928640341465

1 × $64.55

Insize 4120-11, METRIC THREAD RING GAGE, GO, M11x1.5, 6928640341465

1 × $64.55 -

×

3M 87429, Final Finishing Pads 10199NA4PK, 3 3/4 in x 6 in x 5/8 in, Replaces 0000 Steel Wool, 7100096075, 4 pads per pack

6 × $3.12

3M 87429, Final Finishing Pads 10199NA4PK, 3 3/4 in x 6 in x 5/8 in, Replaces 0000 Steel Wool, 7100096075, 4 pads per pack

6 × $3.12 -

×

3M 82596, Hot Melt Adhesive 3762 AE, Tan, 0.45 in x 12 in, 7100023019, 11 LBS/Case

11 × $20.76

3M 82596, Hot Melt Adhesive 3762 AE, Tan, 0.45 in x 12 in, 7100023019, 11 LBS/Case

11 × $20.76 -

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

Dynabrade 91162 3/8" W x 13" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.60

Dynabrade 91162 3/8" W x 13" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.60

Standard Abrasives 830015, Aluminum Oxide Buff and Blend GP Roll, BB-GP, Fine, 4 in x 30 ft, 7000046839

$88.04

Factory Stock, 7-10 Day Leadtime

Our Standard Abrasives Aluminum Oxide Buff and Blend Roll combines nylon strands and aluminum oxide with a resin bond, resulting in an open web that is responsive and durable enough for deburring, cleaning, blending and finishing. Available in a versatile range of grades and sizes, you can choose the right roll for your application.

Choosing the Right Buff & Blend Material

Each of the Standard Abrasives Buff & Blend materials offers unique benefits. Standard Abrasives Buff & Blend materials include: GP, AP, HS and HS-F.

GP is a general purpose material that delivers a high cut rate and consistent finish. It is the most middle-of-the-road, multi-purpose material among all the standard abrasives buff & blend materials. It’s great for general-duty applications, like intermediate cleaning, blending, deburring and finishing – striking a balance between aggressive cutting action and fine finishing. AP material is a cut above GP in terms of its aggressiveness, and it will produce a coarser finish than GP material.

HS and HS-F material are both high strength. The material is very tear resistant, so it’s a good match for final finishing on irregularly-shaped parts, because it will not break down or fray when it comes in contact with contours and extrusions. HS-F material is the best material for light deburring and finishing, because the fineness of the mineral produces a consistent, soft scratch pattern when sanding brass, steel, bronze and stainless steel surfaces.

Standard Abrasives™ Aluminum Oxide Buff and Blend Rolls come in varying widths, from 1 inch to 38 inches. We purposefully designed these roles in different sizes, so they would fit with a range of sanding tools. Whether the workpiece is large or small, it’s likely one of these widths will be a good match for the size of the workpiece. These materials may be used on orbital or straight-line sanders to produce matte and satin finishes or may be cut and shaped for hand-sanding applications.

The Many Benefits of Open Web Abrasives

Every Standard Abrasives™ Aluminum Oxide Buff and Blend Roll features nonwoven nylon strands and aluminum oxide mineral mixed with resin. Gaps between the nylon fibers allow unwanted swarf to escape, enhancing load resistance. As the abrasive is less likely to clog with debris, the mineral keeps cutting sharper, longer. Wear and tear from excess buildup is reduced. Consequently, abrasive service life increases. The open web material is also waterproof and may be used with lubricants, which help to keep the abrasive running cool and wash away swarf. The load-resistant properties of the web, combined with the swarf-cleaning action of the lubricant, help to prevent workpiece contamination. As debris clears away, the likelihood of particles smearing or blemishing the substrate decreases. Rolls may be used on a variety of substrates: ferrous and non-ferrous metals, aluminum, high nickel /chrome alloys and stainless steel. This abrasive is designed to help you tackle your industrial application with efficiency and ease.