-

×

3M 16831, Urethane Seam Sealer, 08361, Gray, 310 mL Foil Pack, 7000120461, 6 per case

6 × $28.47

3M 16831, Urethane Seam Sealer, 08361, Gray, 310 mL Foil Pack, 7000120461, 6 per case

6 × $28.47 -

×

ACS Diamond Cloth Belt, CX1250 1/2" X 18" 125U

12 × $5.70

ACS Diamond Cloth Belt, CX1250 1/2" X 18" 125U

12 × $5.70 -

×

3M 16611, Accuspray Atomizing Head, Clear, 1.8 mm, 7000000500 (4 Nozzles/Kit)

6 × $29.64

3M 16611, Accuspray Atomizing Head, Clear, 1.8 mm, 7000000500 (4 Nozzles/Kit)

6 × $29.64 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

6 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

6 × $43.00 -

×

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94

3M™ 72013, Adapter 529-04-50, 110-120 VAC, 7000131705, 1 EA/Case

1 × $129.94 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 74u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 74u

12 × $7.60 -

×

3M 01875, Charge-Collection Solar Tape 3011, 2 mm x 1200 m, 7010312686

9 × $602.05

3M 01875, Charge-Collection Solar Tape 3011, 2 mm x 1200 m, 7010312686

9 × $602.05 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 125u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 125u

12 × $7.60 -

×

3M 29848, Sanding Screen, 180 Grit, 15 in x NH, 7100160815

12 × $4.03

3M 29848, Sanding Screen, 180 Grit, 15 in x NH, 7100160815

12 × $4.03 -

×

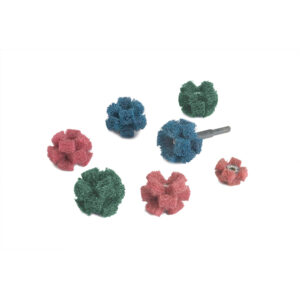

3M 13372, Scotch-Brite Star, 3 in A CRS LS, 7000120967

50 × $6.76

3M 13372, Scotch-Brite Star, 3 in A CRS LS, 7000120967

50 × $6.76 -

×

3M 03738, Scotch-Brite Cut and Polish Unitized Wheel, CP-UW, 7A Medium, 3 in x 3/4 in x 3/8 in, 7010364917

10 × $24.95

3M 03738, Scotch-Brite Cut and Polish Unitized Wheel, CP-UW, 7A Medium, 3 in x 3/4 in x 3/8 in, 7010364917

10 × $24.95 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

Insize ISV-1H4300, RIGID BORESCOPE, 11.89", 6928640323799

1 × $2,411.58

Insize ISV-1H4300, RIGID BORESCOPE, 11.89", 6928640323799

1 × $2,411.58 -

×

Standard Abrasives 727395, Buff and Blend Cross Buff HS, A/O Coarse, 2 in x 1/2 in x 2 Ply x 8-32, 7010299537

25 × $5.84

Standard Abrasives 727395, Buff and Blend Cross Buff HS, A/O Coarse, 2 in x 1/2 in x 2 Ply x 8-32, 7010299537

25 × $5.84 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

ACS 3" Diamond Roloc Disc, 120 Mesh, W/ Plastic Button

1 × $27.50

ACS 3" Diamond Roloc Disc, 120 Mesh, W/ Plastic Button

1 × $27.50 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

2 × $502.78

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

2 × $502.78 -

×

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

25 × $4.57

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

25 × $4.57 -

×

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series, 30,000RPM, 33431

1 × $950.00

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series, 30,000RPM, 33431

1 × $950.00 -

×

3M 94717, Cubitron ll Cloth Belt 947A, 80+ X-weight, 1 in x 30 in, Fabri-lok, Single-flex, 7010294445, 200 per case

200 × $3.73

3M 94717, Cubitron ll Cloth Belt 947A, 80+ X-weight, 1 in x 30 in, Fabri-lok, Single-flex, 7010294445, 200 per case

200 × $3.73 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47 -

×

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 9u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 9u

12 × $7.60 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50 -

×

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $453.00 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

1 × $420.00 -

×

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00 -

×

Standard Abrasives 725004, Buff and Blend Cross Buff GP, A/O Coarse, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7000047136

50 × $6.37

Standard Abrasives 725004, Buff and Blend Cross Buff GP, A/O Coarse, 1-1/2 in x 1/2 in x 2 Ply x 8-32, 7000047136

50 × $6.37 -

×

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

40 × $11.64

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

40 × $11.64 -

×

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

2 × $388.51

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

2 × $388.51 -

×

Norton 66261199696 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 7AM U2305, 40 Each

40 × $13.04

Norton 66261199696 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 7AM U2305, 40 Each

40 × $13.04 -

×

3M 10115, Synthetic Steel Wool Pads, #3 Coarse, 7000051986

18 × $2.69

3M 10115, Synthetic Steel Wool Pads, #3 Coarse, 7000051986

18 × $2.69 -

×

3M 26120, PPS Series 2.0 Adapter, Type S28, 17.5 mm Female, 19 TPI

Thread, 7100135956

1 × $25.96

3M 26120, PPS Series 2.0 Adapter, Type S28, 17.5 mm Female, 19 TPI

Thread, 7100135956

1 × $25.96 -

×

Dynabrade 01185 Vane Set (4pk)

1 × $26.54

Dynabrade 01185 Vane Set (4pk)

1 × $26.54 -

×

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $1,245.00

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $1,245.00 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series, 25,000RPM, 33421

1 × $950.00

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series, 25,000RPM, 33421

1 × $950.00 -

×

Norton 66623325035 - 2" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep Green TR Non-Woven Surface Preparation Disc, 50 Each

50 × $1.70

Norton 66623325035 - 2" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep Green TR Non-Woven Surface Preparation Disc, 50 Each

50 × $1.70 -

×

3M 14316, Marine Adhesive Sealant 4000 UV, Black, 295 mL Cartridge, 7010367955, 12/Case

12 × $24.95

3M 14316, Marine Adhesive Sealant 4000 UV, Black, 295 mL Cartridge, 7010367955, 12/Case

12 × $24.95 -

×

Dynabrade 51862 .4 hp Trim Router (Complete), 30,000 RPM, 1/4 Collet

1 × $714.00

Dynabrade 51862 .4 hp Trim Router (Complete), 30,000 RPM, 1/4 Collet

1 × $714.00 -

×

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51 -

×

3M 80835, Flexible Diamond Hand File 6210J, No 2, Yellow, 18, N40, 7000082160, 10 Per Case

1 × $93.34

3M 80835, Flexible Diamond Hand File 6210J, No 2, Yellow, 18, N40, 7000082160, 10 Per Case

1 × $93.34 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06 -

×

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,520.00

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,520.00 -

×

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series with Brake, 40,000RPM, 33445

1 × $975.00

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series with Brake, 40,000RPM, 33445

1 × $975.00 -

×

3M 04229, Scotch-Brite Hand Pad 7447B, HP-HP, A/O Very Fine, 6 in x 9 in, 7000027560, 60 ea/Case

1 × $77.93

3M 04229, Scotch-Brite Hand Pad 7447B, HP-HP, A/O Very Fine, 6 in x 9 in, 7000027560, 60 ea/Case

1 × $77.93

Standard Abrasives 827600, Buff and Blend GP Power Pad, 6 in x 9 in, A VFN, 7010330610, 50 ea/Case

$99.05

Factory Stock, 7-10 Day Leadtime, Priced Per Case

Standard Abrasives Buff and Blend Power Pad is pre-cut to a convenient size and has added stiffness for use by hand or with tools. Use it for deburring, polishing, cleaning, and surface preparation on metal, composite or plastic surfaces. It can be a good alternative to steel wool, files, scrapers, wire brushes and sandpaper sheets.

Versatile Pad, Consistent Results

Our Standard Abrasives™ Buff and Blend Power Pad is designed to help you achieve consistent results on solid surfaces, painted panels, and other materials. Used by hand or on a power tool such as a jitterbug, these pre-cut pads are suitable for many applications, such as:

- General purpose maintenance tasks

- Edge deburring on aluminum extrusions

- Deburring aluminum die cast flashing

- Radiusing edges on precision machined or contoured parts

- Removing heavy surface oxidation and surface coatings for part inspection

- Surface preparation prior to coating

- Rust removal

- Blending mill marks, tool marks, mismatches, and coated abrasive disc scratch patterns

- Reducing uneven edges

- Producing decorative finishes

This versatile pad features a non-woven 3D web of fibers that conforms to irregular surfaces for a clean, consistent finish without cutting into the base material. For long-lasting utility, the open web is load and heat resistant, and the pad can be washed for re-use. An alternative to steel wool, it provides consistent results without rusting or leaving steel splinters behind.

Choosing the Right Buff & Blend Material

We make Power Pads with two mineral options to suit different application requirements: very fine grade aluminum oxide and very fine grade silicon carbide. Aluminum oxide offers a more aggressive cut and longer use, while silicon carbide typically provides a finer finish.

Each of the Standard Abrasives Buff & Blend materials offers unique benefits. Standard Abrasives™ Power Pads are offered with GP, HP and HS material.

GP is a general purpose material that delivers a high cut rate and consistent finish. It is the most middle-of-the-road, multi-purpose material among all the standard abrasives buff & blend materials. It’s great for general-duty applications such as intermediate cleaning, blending, deburring and finishing – striking a balance between aggressive cutting action and fine finishing.

HP material is ideal for deburring and heavy edge work. Its durable construction gives it an aggressive cut and makes it suitable for edge deburring on aluminum extrusions, deburring aluminum die cast flashing, removing heavy surface oxidation, and the like.

HS is high strength material with increased tear-resistance, so it’s a good match for light deburring and final finishing on irregularly-shaped parts, because it will not break down or fray when it comes in contact with contours and extrusions. It is an excellent choice for high luster and decorative finishes, and tasks such as final finishing on non-ferrous die cast molded parts, finishing on all metals and plated plastics, and polishing pipe threads and edges of molded glass containers.

Load-Resistant Material Boosts Life and Performance

Standard Abrasives™ Buff and Blend material is load-resistant to keep you cutting with fresh mineral. The gaps in the open web allow unwanted swarf to escape. Consequently, less debris clogs the abrasive, so the mineral can stay fresh, keep cutting sharp and deliver a consistent cut over the life of the product. As the fibers break down and fresh mineral is exposed, it reduces the likelihood of dull or blunt mineral smearing the surface, contributing to cleaner surfaces and less re-work. Furthermore, manual fatigue that may result from applying heavy pressure to a dull abrasive is reduced.

The Many Benefits of Standard Abrasives™ Buff and Blend Products

Standard Abrasives™ Buff and Blend products invigorate deburring, cleaning, blending and finishing applications by helping operators reduce finishing steps, minimize costs and achieve greater throughput. Each Buff and Blend product and grade offers unique benefits, so operators can choose from a versatile range of options to ensure optimal performance on specific applications.