-

×

Insize ISP-AZ3020, PROFILE PROJECTOR, 12" DIA, without edge detector, 6928640322655

1 × $19,809.89

Insize ISP-AZ3020, PROFILE PROJECTOR, 12" DIA, without edge detector, 6928640322655

1 × $19,809.89 -

×

3M 36900, Interior Protection Automotive Seat Cover, 250 per box, 7010328094

1 × $100.09

3M 36900, Interior Protection Automotive Seat Cover, 250 per box, 7010328094

1 × $100.09 -

×

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

36 × $18.24

3M 35083, EMI Copper Foil Shielding Tape 1181, 1/4 in x 18 yd (6,35 mm x 16,5 m), 7000132168

36 × $18.24 -

×

Norton 66261199696 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 7AM U2305, 40 Each

40 × $13.04

Norton 66261199696 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 7AM U2305, 40 Each

40 × $13.04 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

Standard Abrasives 840031, Quick Change Surface Conditioning FE Disc, A/O Coarse, TSM, Brown, 3/4 in, QS75KM, 7000046845, 50/case

50 × $0.84

Standard Abrasives 840031, Quick Change Surface Conditioning FE Disc, A/O Coarse, TSM, Brown, 3/4 in, QS75KM, 7000046845, 50/case

50 × $0.84 -

×

3M 62607, Scotch-Weld Threadlocker TL42, Blue, 250 mL Bottle, 7100039192, 2/case

2 × $126.95

3M 62607, Scotch-Weld Threadlocker TL42, Blue, 250 mL Bottle, 7100039192, 2/case

2 × $126.95 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76 -

×

3M 81729, Disc Pad Face Plate Ribbed, 9 in Hard Black, 7000148244

10 × $53.49

3M 81729, Disc Pad Face Plate Ribbed, 9 in Hard Black, 7000148244

10 × $53.49 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06 -

×

3M 13180, Scotch-Brite Multi-Finishing Wheel, MU-WL, 2S Medium, 6 in x 3 in x 1 in, 7000148248

1 × $133.38

3M 13180, Scotch-Brite Multi-Finishing Wheel, MU-WL, 2S Medium, 6 in x 3 in x 1 in, 7000148248

1 × $133.38 -

×

Norton 66254489957 Wheel, Vortex-7am, 6" X 1/2" X 1" C2312 Nor VTME7 PH VTC+, 4 Each

4 × $84.19

Norton 66254489957 Wheel, Vortex-7am, 6" X 1/2" X 1" C2312 Nor VTME7 PH VTC+, 4 Each

4 × $84.19 -

×

3M 25783, Scotch-Weld PUR Applicator Housing/Shroud Assembly Kit, 7000028623

1 × $97.30

3M 25783, Scotch-Weld PUR Applicator Housing/Shroud Assembly Kit, 7000028623

1 × $97.30 -

×

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

3M 26106, PPS Series 2.0 Adapter, Type S22, 8 mm Male, 0.75 mm Thread, 7100135958

1 × $25.45

3M 26106, PPS Series 2.0 Adapter, Type S22, 8 mm Male, 0.75 mm Thread, 7100135958

1 × $25.45 -

×

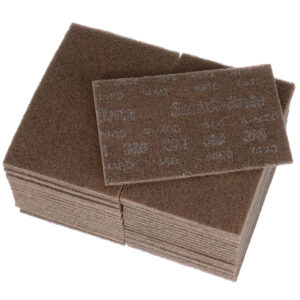

3M 18451, Scotch-Brite Heavy Duty Hand Pad 7440B, HP-HP, A/O Medium, 6 in x 9 in, 7000000715, 40 ea/Case

1 × $139.68

3M 18451, Scotch-Brite Heavy Duty Hand Pad 7440B, HP-HP, A/O Medium, 6 in x 9 in, 7000000715, 40 ea/Case

1 × $139.68 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

Dynabrade 78293 3" Dia. x 2S Fine, Type R Unitized Locking-Type Disc, 25/pack

25 × $12.89

Dynabrade 78293 3" Dia. x 2S Fine, Type R Unitized Locking-Type Disc, 25/pack

25 × $12.89 -

×

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67

3M 22408, Roloc Disc 361F, P100 YF-weight, TR, 1-1/2 in, Die R150S, 7000045101

500 × $0.67 -

×

3M 92297, Drywall Quick Clip Pole Sander DRPS-0010, 3-5/16 in x 9-1/4 in, 7010332448

4 × $10.43

3M 92297, Drywall Quick Clip Pole Sander DRPS-0010, 3-5/16 in x 9-1/4 in, 7010332448

4 × $10.43 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00 -

×

Norton 66261013403 - 3" X 1/2" Extra Coarse Grade Silicon Carbide Bear-Tex Rapid Strip TR Stripping Disc, 10 Each

10 × $8.06

Norton 66261013403 - 3" X 1/2" Extra Coarse Grade Silicon Carbide Bear-Tex Rapid Strip TR Stripping Disc, 10 Each

10 × $8.06

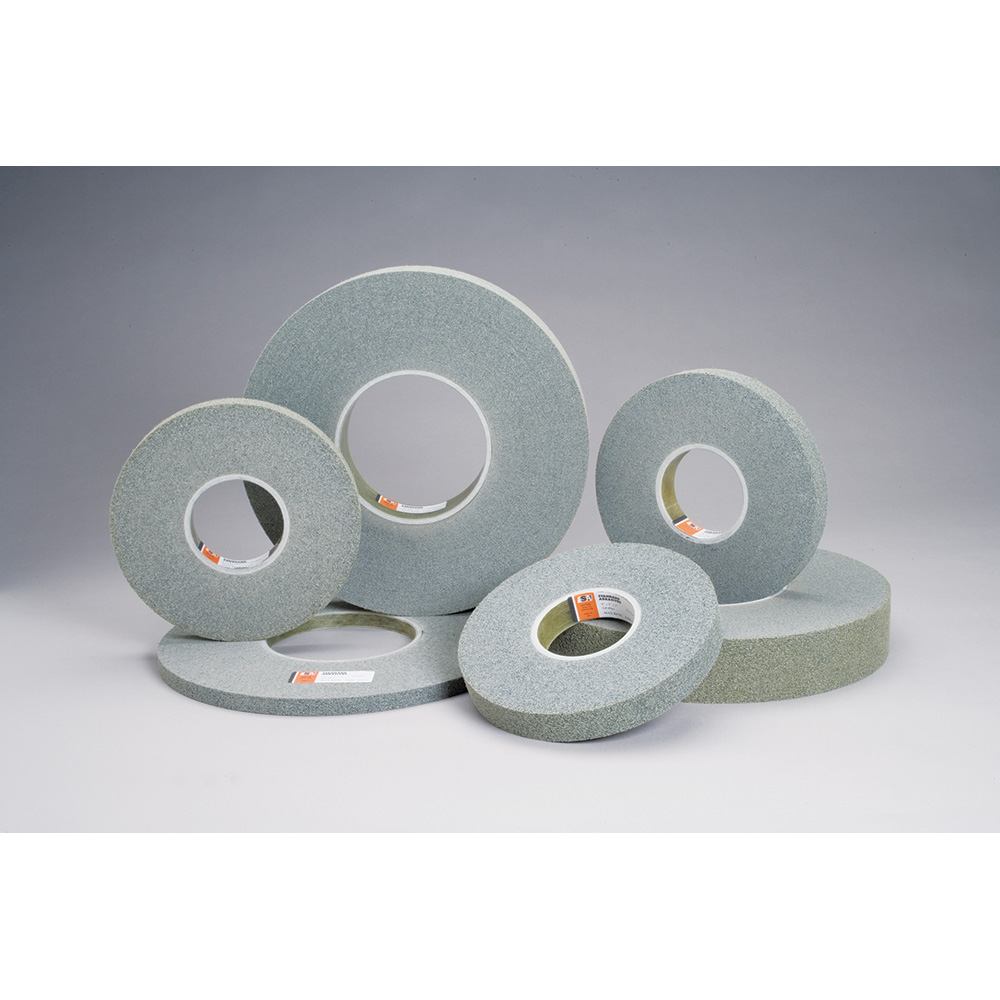

Standard Abrasives 854853, GP Plus Wheel, 12 in x 2 in x 5 in 9S FIN, 7000046903

$297.66

Factory Stock, 7-10 Day Leadtime

Strong and durable, the Standard Abrasives General Purpose Plus Wheel is the best Standard Abrasives wheel for deburring, blending and cleaning when a consistent cut rate and wheel durability are a primary requirement.

Recommended Applications

The Standard Abrasives™ General Purpose Plus Wheel is a convolute wheel that winds an open web of abrasive grain, nylon fibers and resin around a core. The wheel provides excellent durability for the toughest edge and flat surface deburring applications. It’s great for medium to heavy burr removal on parts with heavy edges and turbine blades. It may also be used for machine and belt mark blending, as well as fine finishing on parts like surgical tools.

The wheel utilizes either silicon carbide or aluminum oxide – and are available in medium to hard densities, ranging from 8 to 10. Together, these properties combine to cut aggressively, maintain wheel shape and stand up to edges. Nylon fibers in the open web break down while deburring the surface, exposing fresh, sharp mineral. The wheel breakdown contributes to consistent cutting action. Gaps between the nylon fibers allow swarf and debris to escape, keeping the mineral sharp and preventing blunt or dull edges that might gouge or blemish the surface of the workpiece. Subsequently, smear-resistant finishes result.

Tips for Optimal Use

As a convolute wheel, the Standard Abrasives™ General Purpose Plus Wheel should run at recommended operating speeds, using low to medium pressure, and in the direction of the arrow imprinted on the wheel. Following these recommended measures will help to ensure operator safety and optimal performance of the wheel. Using lubricants may also help wash away unwanted swarf and debris and keep the abrasive running cool. The wheel may be used on straight shaft stationary and portable tools, feed-through machines and automated equipment. The versatile range of tools that the wheel may be used with gives operators an added level of flexibility and convenience, as they may manipulate the wheel to meet their unique project needs.