-

×

3M 05209, Hookit Sanding Block D/F, 70MM x 396MM, 7000028312

1 × $199.50

3M 05209, Hookit Sanding Block D/F, 70MM x 396MM, 7000028312

1 × $199.50 -

×

3M 5677, DISC PAD HOLDER 914, 4 IN X 1/8 IN X 3/8 IN M14-2.0 INTERNAL, 7010299278

1 × $31.71

3M 5677, DISC PAD HOLDER 914, 4 IN X 1/8 IN X 3/8 IN M14-2.0 INTERNAL, 7010299278

1 × $31.71 -

×

Dynabrade 22090 2-3/4" x 5" Hand Sanding Block

1 × $54.43

Dynabrade 22090 2-3/4" x 5" Hand Sanding Block

1 × $54.43 -

×

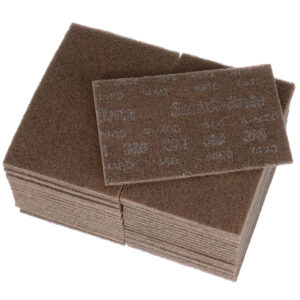

3M 18451, Scotch-Brite Heavy Duty Hand Pad 7440B, HP-HP, A/O Medium, 6 in x 9 in, 7000000715, 40 ea/Case

1 × $139.68

3M 18451, Scotch-Brite Heavy Duty Hand Pad 7440B, HP-HP, A/O Medium, 6 in x 9 in, 7000000715, 40 ea/Case

1 × $139.68 -

×

Norton 66261014792 - 2" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc 160 Each

160 × $2.04

Norton 66261014792 - 2" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc 160 Each

160 × $2.04

Standard Abrasives 852833, LDW Wheel, 12 in x 2 in x 5 in 7S FIN, 7010330345

$295.08

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.