-

×

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75

3M 22396, Roloc Disc 361F, 36 YF-weight, TR, 1-1/2 in, Die R150S, 7000045091

500 × $0.75 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58 -

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33 -

×

Dynabrade 92187 1" W x 30" L 80 Grit A/Z DynaCut Belt, 50/pack

50 × $3.54

Dynabrade 92187 1" W x 30" L 80 Grit A/Z DynaCut Belt, 50/pack

50 × $3.54 -

×

Norton 66261096557 - 3" X 1/2" Blaze Rapid Strip Ceramic Alumina Extra Coarse Grade Non- Woven Abrasive Disc With Quick Change TR III Attachment, 25 Each

25 × $9.44

Norton 66261096557 - 3" X 1/2" Blaze Rapid Strip Ceramic Alumina Extra Coarse Grade Non- Woven Abrasive Disc With Quick Change TR III Attachment, 25 Each

25 × $9.44

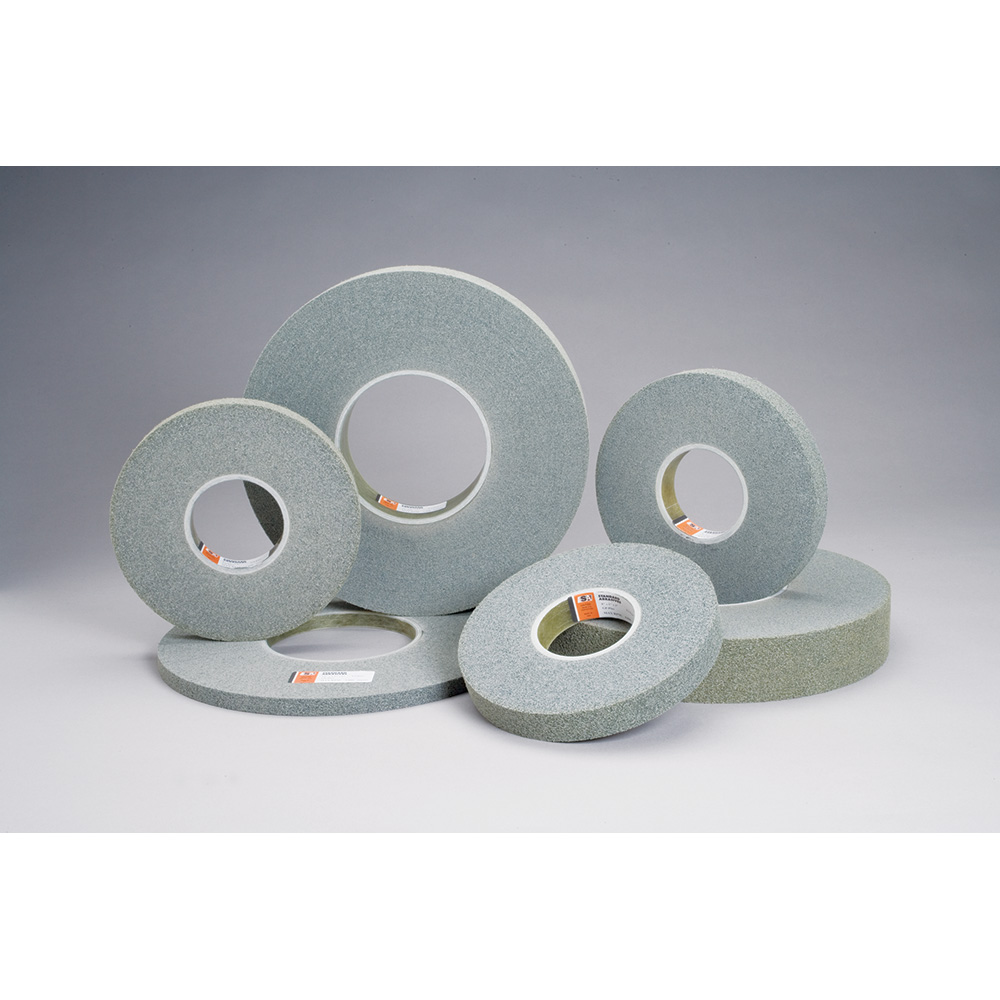

Standard Abrasives 852733, LDW Wheel, 8 in x 1/2 in x 3 in 7S FIN, 7010330344

$78.45

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.