-

×

Norton 66261199696 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 7AM U2305, 40 Each

80 × $13.04

Norton 66261199696 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 7AM U2305, 40 Each

80 × $13.04 -

×

Dynabrade 60218 - 15,000 lb. Jack with 1/2" Vi-Damp Pad

2 × $312.11

Dynabrade 60218 - 15,000 lb. Jack with 1/2" Vi-Damp Pad

2 × $312.11 -

×

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

4 × $420.00

Dynabrade 40610 Electric Dynafile II Abrasive Belt Tool

4 × $420.00 -

×

Dynabrade 60213 - 15,000 lb. Jack with 3/4" Vi-Sorb Pad

2 × $310.50

Dynabrade 60213 - 15,000 lb. Jack with 3/4" Vi-Sorb Pad

2 × $310.50 -

×

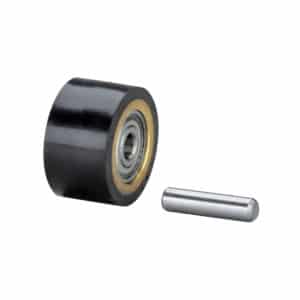

Dynabrade 11076 Contact Wheel Ass'y, 7/16" Dia. x 3/8" W x 3/8" I.D., Crown Face, Steel

1 × $40.81

Dynabrade 11076 Contact Wheel Ass'y, 7/16" Dia. x 3/8" W x 3/8" I.D., Crown Face, Steel

1 × $40.81 -

×

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

75 × $1.98

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

75 × $1.98 -

×

Dynabrade 78122 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.79

Dynabrade 78122 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.79 -

×

Norton 66623325035 - 2" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep Green TR Non-Woven Surface Preparation Disc, 50 Each

50 × $1.70

Norton 66623325035 - 2" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep Green TR Non-Woven Surface Preparation Disc, 50 Each

50 × $1.70 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00 -

×

Norton 66261014792 - 2" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc 160 Each

320 × $2.04

Norton 66261014792 - 2" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc 160 Each

320 × $2.04 -

×

3M 26613, Accuspray Atomizing Head Refill Pack for 3M PPS Series 2.0,Green, 1.3 mm, 7100141415 (4 Nozzles/Kit)

6 × $31.20

3M 26613, Accuspray Atomizing Head Refill Pack for 3M PPS Series 2.0,Green, 1.3 mm, 7100141415 (4 Nozzles/Kit)

6 × $31.20 -

×

Dynabrade 60215 - 20,000 lb. Jack with 3/4" Vi-Sorb Pad

2 × $297.88

Dynabrade 60215 - 20,000 lb. Jack with 3/4" Vi-Sorb Pad

2 × $297.88 -

×

Dynabrade 90874 2" Dia. Very Fine NWN DynaBrite Locking-Type Disc, 25/pack

75 × $1.89

Dynabrade 90874 2" Dia. Very Fine NWN DynaBrite Locking-Type Disc, 25/pack

75 × $1.89 -

×

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

2 × $2,022.00

Dynabrade 11486 Dynabelter Accu-Grinder Abrasive Belt Tool, Heavy-Duty

2 × $2,022.00 -

×

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $36.60

Dynabrade 11078 Contact Wheel Ass'y, 5/8" Dia. x 3/8" W x 3/8" I.D., Crown Face, 70 Duro Rubber

1 × $36.60 -

×

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

50 × $4.48

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

50 × $4.48 -

×

Norton 66261014921 - 2" X 1/8" 50 - 80 Grit Coarse Grade Aluminum Oxide Bear-Tex Speed-Lok Rapid Blend Gray TR Non-Woven Unified Wheel, 60 Each

120 × $6.44

Norton 66261014921 - 2" X 1/8" 50 - 80 Grit Coarse Grade Aluminum Oxide Bear-Tex Speed-Lok Rapid Blend Gray TR Non-Woven Unified Wheel, 60 Each

120 × $6.44 -

×

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $43.25

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $43.25 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00 -

×

3M 07959, Sanding Screen, 100 Grit, 7-7/8 in x 3/16 in, 7100160279

40 × $1.60

3M 07959, Sanding Screen, 100 Grit, 7-7/8 in x 3/16 in, 7100160279

40 × $1.60 -

×

Dynabrade 15346 Contact Wheel Ass'y, 2" Dia. x 5/8" W x 5/8" I.D., Crown Face, 40 Duro Rubber

1 × $128.99

Dynabrade 15346 Contact Wheel Ass'y, 2" Dia. x 5/8" W x 5/8" I.D., Crown Face, 40 Duro Rubber

1 × $128.99 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00 -

×

Norton 66261013403 - 3" X 1/2" Extra Coarse Grade Silicon Carbide Bear-Tex Rapid Strip TR Stripping Disc, 10 Each

20 × $8.06

Norton 66261013403 - 3" X 1/2" Extra Coarse Grade Silicon Carbide Bear-Tex Rapid Strip TR Stripping Disc, 10 Each

20 × $8.06 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

200 × $11.50

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

200 × $11.50 -

×

Dynabrade 60219 - 20,000 lb. Jack with 1/4" Vi-Damp Pad

1 × $326.13

Dynabrade 60219 - 20,000 lb. Jack with 1/4" Vi-Damp Pad

1 × $326.13 -

×

3M 29825, Sanding Screen, 60 Grit, 20 in x NH, 7100160253

22 × $13.48

3M 29825, Sanding Screen, 60 Grit, 20 in x NH, 7100160253

22 × $13.48 -

×

Dynabrade 60204 - 30,000 lb. Jack with No Pad

2 × $321.45

Dynabrade 60204 - 30,000 lb. Jack with No Pad

2 × $321.45 -

×

Dynabrade 94820 - 3/8" ID, 5' Long Air Hose Assembly, Female/ Male Fitting Ends Included

1 × $54.62

Dynabrade 94820 - 3/8" ID, 5' Long Air Hose Assembly, Female/ Male Fitting Ends Included

1 × $54.62 -

×

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

10 × $2.70

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

10 × $2.70 -

×

Dynabrade 60205 - 3,000 lb. Jack with 1/4" Vi-Sorb Pad

1 × $194.89

Dynabrade 60205 - 3,000 lb. Jack with 1/4" Vi-Sorb Pad

1 × $194.89 -

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

2 × $28,988.00

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

2 × $28,988.00 -

×

3M 26618, Accuspray Atomizing Head Refill Pack for 3M PPS Series 2.0,Clear, 1.8 mm, 7100141416 (4 Nozzles/Kit)

6 × $31.20

3M 26618, Accuspray Atomizing Head Refill Pack for 3M PPS Series 2.0,Clear, 1.8 mm, 7100141416 (4 Nozzles/Kit)

6 × $31.20 -

×

Dynabrade 60200 - 3,000 lb. Jack with No Pad

2 × $199.77

Dynabrade 60200 - 3,000 lb. Jack with No Pad

2 × $199.77 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43 -

×

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

40 × $11.64

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

40 × $11.64 -

×

Norton 66261096557 - 3" X 1/2" Blaze Rapid Strip Ceramic Alumina Extra Coarse Grade Non- Woven Abrasive Disc With Quick Change TR III Attachment, 25 Each

25 × $9.14

Norton 66261096557 - 3" X 1/2" Blaze Rapid Strip Ceramic Alumina Extra Coarse Grade Non- Woven Abrasive Disc With Quick Change TR III Attachment, 25 Each

25 × $9.14 -

×

Dynabrade 60206 - 3,000 lb. Jack with 1/2" Vi-Sorb Pad

1 × $205.91

Dynabrade 60206 - 3,000 lb. Jack with 1/2" Vi-Sorb Pad

1 × $205.91 -

×

Dynabrade 92209 1/8" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.02

Dynabrade 92209 1/8" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.02 -

×

Dynabrade 11080 Contact Wheel Ass'y, 1" Dia. x 3/8" W x 3/8" I.D., Round Radiused Face, 70 Duro Rubber

1 × $36.49

Dynabrade 11080 Contact Wheel Ass'y, 1" Dia. x 3/8" W x 3/8" I.D., Round Radiused Face, 70 Duro Rubber

1 × $36.49

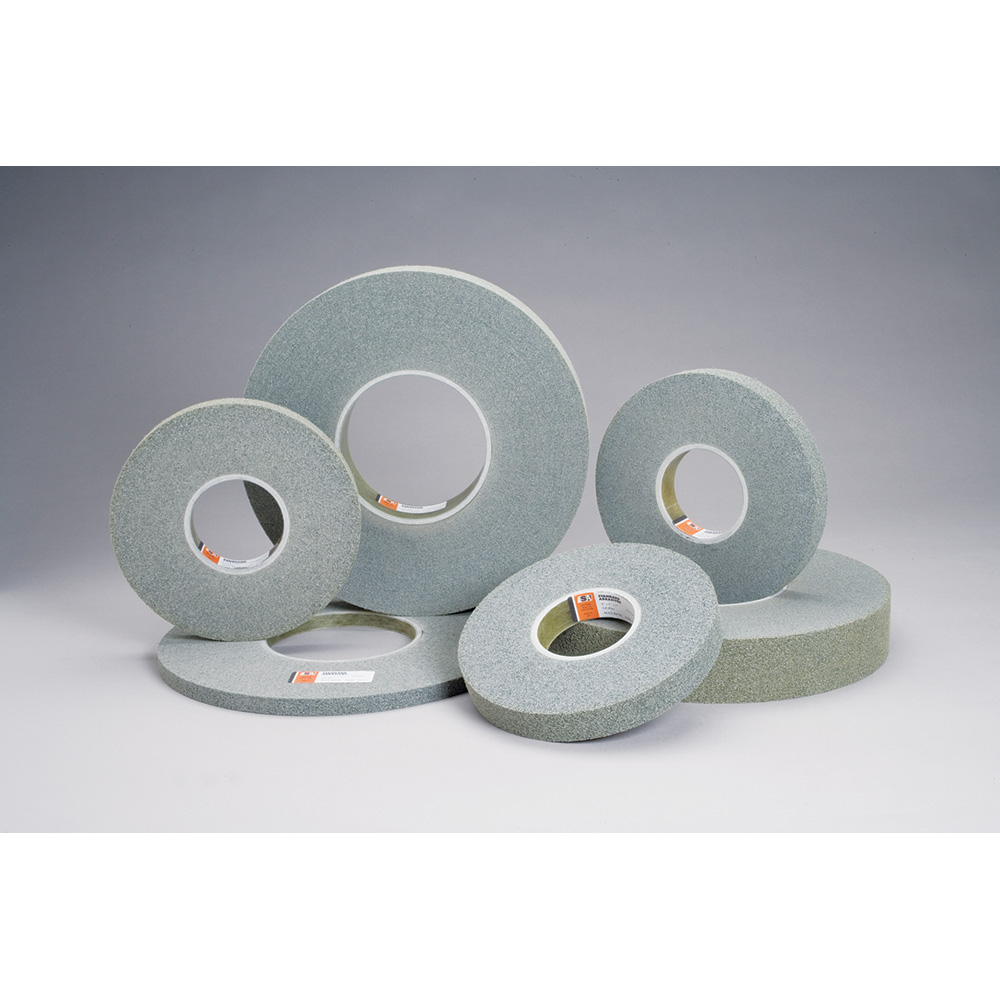

Standard Abrasives 852433, LDW Wheel, 8 in x 2 in x 3 in 7S FIN, 7000047110

$201.26

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.

Choosing High vs. Low Densities

Our Standard Abrasives™ Light Deburring Wheel utilizes a fine grade silicon carbide mineral. These wheels vary in density, ranging from 6 to 8. Higher density wheels tend to be more durable and have a longer service life. Lower density wheels indicate softer feel. This lower density enables the wheel to be more flexible and conform to the substrate. Light deburring wheels tend to be less aggressive and finish finer than other convolute wheels.

Smear-Resistant for A Brighter Finish

These wheels are convolute wheels, meaning they must be run in one direction as indicated by the arrow on the side of the wheel. The abrasive web, made with resin and silicon carbide mineral, is wound around the wheel’s core. The silicon carbide mineral is bonded with a smear-resistant resin that will not smudge or stain the substrate. These attributes contribute to a cleaner, brighter finish on the substrate. Our Light Deburring Wheel is a great starting point for your light blending, polishing, and deburring applications. Consider it a trusted tool for achieving a fine finish on the workpiece.