-

×

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $871.15

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $871.15 -

×

Dynabrade 94990 1/4" Female Composite-Style Coupler with 1/4" Male Plug Assembly

2 × $40.31

Dynabrade 94990 1/4" Female Composite-Style Coupler with 1/4" Male Plug Assembly

2 × $40.31 -

×

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.37

Dynabrade 95848 Dynabrade Gear Oil

1 × $12.37 -

×

Dynabrade 15360 Dynafile III Abrasive Belt Machine for 24" Belts

1 × $896.53

Dynabrade 15360 Dynafile III Abrasive Belt Machine for 24" Belts

1 × $896.53 -

×

Norton 66623325035 - 2" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep Green TR Non-Woven Surface Preparation Disc, 50 Each

50 × $1.76

Norton 66623325035 - 2" 120 Grit Fine Grade Aluminum Oxide Vortex Rapid Prep Green TR Non-Woven Surface Preparation Disc, 50 Each

50 × $1.76 -

×

3M 19769, Utility Cloth Sheet 314D, 9 in x 11 in P150 J-weight, 7000000357

250 × $1.37

3M 19769, Utility Cloth Sheet 314D, 9 in x 11 in P150 J-weight, 7000000357

250 × $1.37 -

×

Dynabrade 79173 2" W x 30" L 60 Grit Ceramic DynaCut Belt, 10/pack

10 × $15.91

Dynabrade 79173 2" W x 30" L 60 Grit Ceramic DynaCut Belt, 10/pack

10 × $15.91 -

×

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $431.21

Dynabrade 51301 .5 hp Straight-Line Die Grinder

1 × $431.21 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

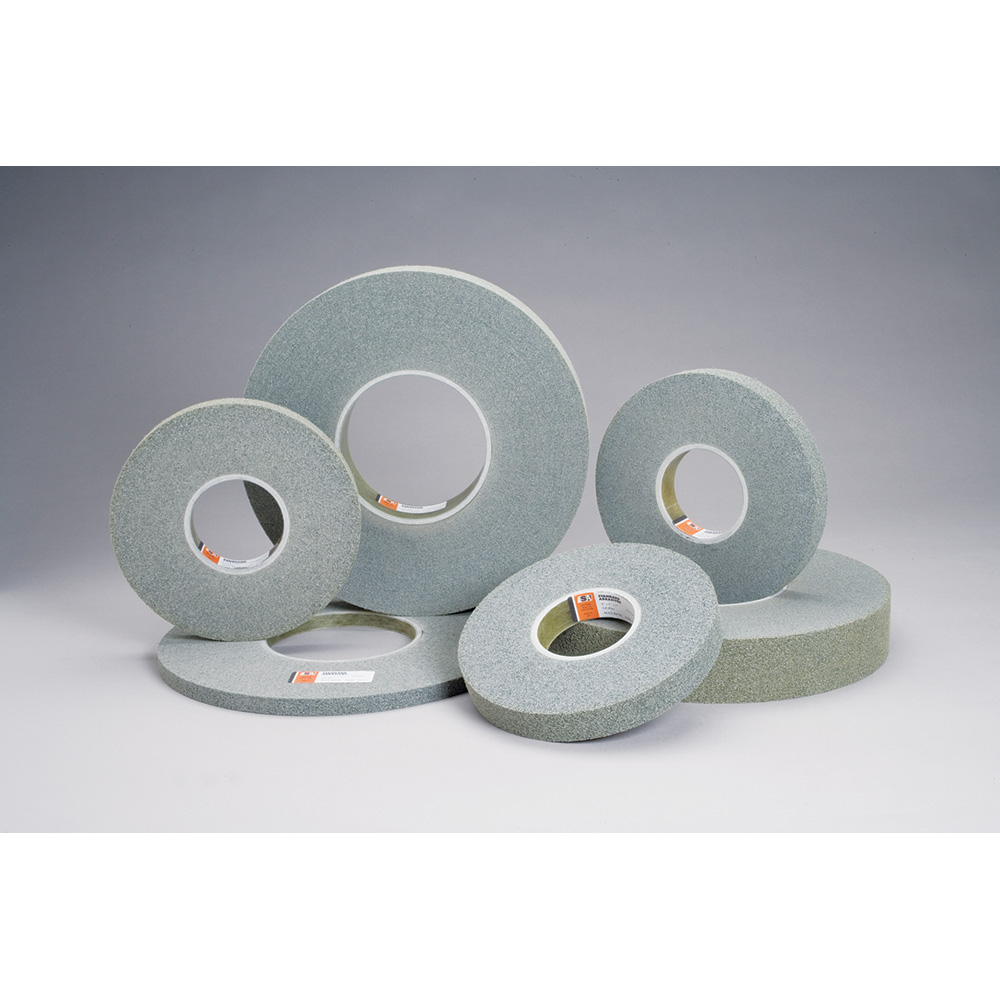

Standard Abrasives 852433, LDW Wheel, 8 in x 2 in x 3 in 7S FIN, 7000047110

$201.26

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.