-

×

3M 14593, Scotch-Brite Cut and Polish Disc, 3" x 1-1/4" x 1/4" A Medium, D5, 7000045941, Box of 10

10 × $16.71

3M 14593, Scotch-Brite Cut and Polish Disc, 3" x 1-1/4" x 1/4" A Medium, D5, 7000045941, Box of 10

10 × $16.71 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

Dynabrade 78423 4-1/2" Dia. x 3/8" Very Fine DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21

Dynabrade 78423 4-1/2" Dia. x 3/8" Very Fine DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21 -

×

3M 35827, Hookit Dust Extraction Flexible Sanding Block, 273 mm x 67 mm, 7100256623

12 × $44.04

3M 35827, Hookit Dust Extraction Flexible Sanding Block, 273 mm x 67 mm, 7100256623

12 × $44.04 -

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52 -

×

Norton 66261014792 - 2" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc 160 Each

160 × $2.04

Norton 66261014792 - 2" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc 160 Each

160 × $2.04 -

×

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21

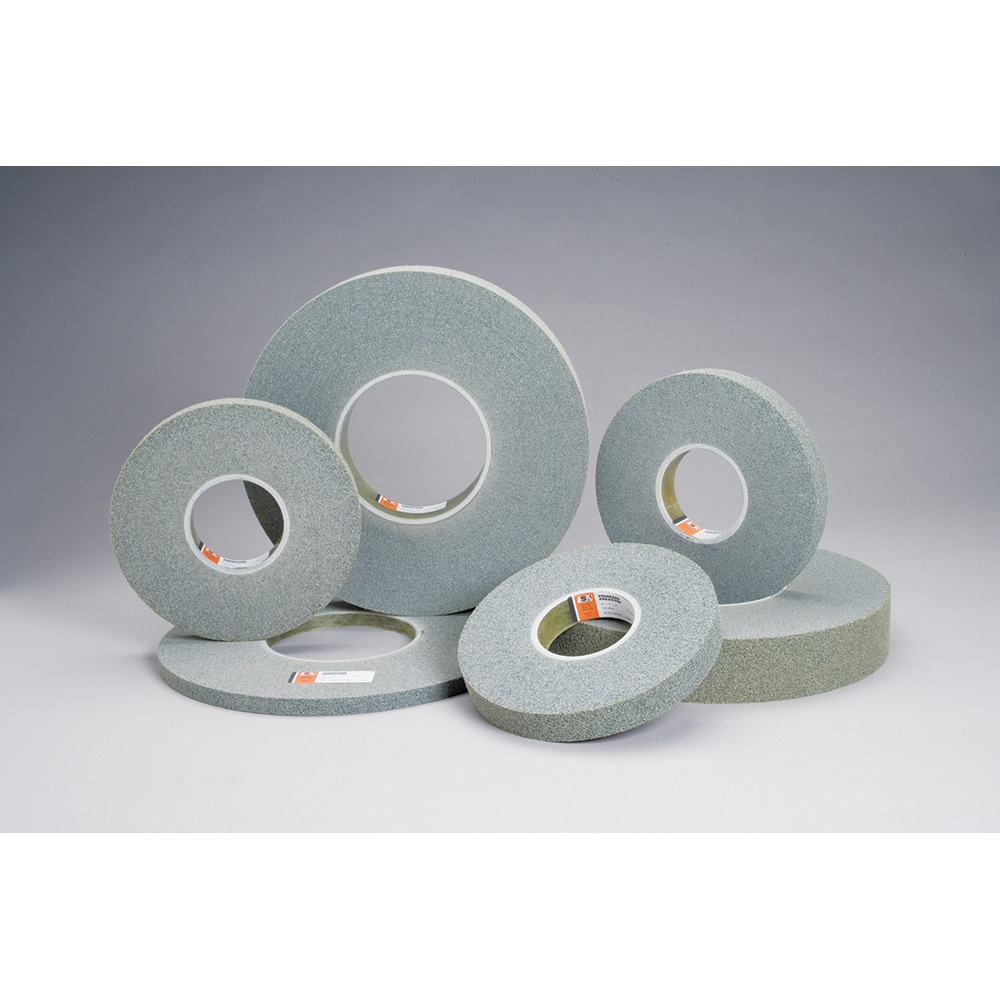

Standard Abrasives 852033, LDW Wheel 6 in x 1/2 in x 1 in 7S FIN, 7010310153

$65.94

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.

Choosing High vs. Low Densities

Our Standard Abrasives™ Light Deburring Wheel utilizes a fine grade silicon carbide mineral. These wheels vary in density, ranging from 6 to 8. Higher density wheels tend to be more durable and have a longer service life. Lower density wheels indicate softer feel. This lower density enables the wheel to be more flexible and conform to the substrate. Light deburring wheels tend to be less aggressive and finish finer than other convolute wheels.

Smear-Resistant for A Brighter Finish

These wheels are convolute wheels, meaning they must be run in one direction as indicated by the arrow on the side of the wheel. The abrasive web, made with resin and silicon carbide mineral, is wound around the wheel’s core. The silicon carbide mineral is bonded with a smear-resistant resin that will not smudge or stain the substrate. These attributes contribute to a cleaner, brighter finish on the substrate. Our Light Deburring Wheel is a great starting point for your light blending, polishing, and deburring applications. Consider it a trusted tool for achieving a fine finish on the workpiece.