-

×

Dynabrade 79054 1/8" W x 24" L 80 Grit A/Z DynaCut Belt, 50/pack

50 × $1.69

Dynabrade 79054 1/8" W x 24" L 80 Grit A/Z DynaCut Belt, 50/pack

50 × $1.69 -

×

Dynabrade 93562 3" Dia. x 1/4"-20 Female Center Thread, 220 Grit, A/O, 3-Ply, J-DynaCut Eyelet Star, 50/pack

50 × $14.74

Dynabrade 93562 3" Dia. x 1/4"-20 Female Center Thread, 220 Grit, A/O, 3-Ply, J-DynaCut Eyelet Star, 50/pack

50 × $14.74 -

×

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,448.42

Dynabrade 11475 Dynabelter Abrasive Belt Tool, Standard Duty

1 × $1,448.42 -

×

Dynabrade 59109 3" Dia. Central Vacuum Dynorbital-Spirit Random Orbital Sander, 3/16" Orbit

1 × $215.90

Dynabrade 59109 3" Dia. Central Vacuum Dynorbital-Spirit Random Orbital Sander, 3/16" Orbit

1 × $215.90 -

×

Dynabrade 48327 .4 hp Straight-Line Die Grinder, Rear Exhaust, 30,000 RPM, 1/4" Collet

1 × $415.47

Dynabrade 48327 .4 hp Straight-Line Die Grinder, Rear Exhaust, 30,000 RPM, 1/4" Collet

1 × $415.47 -

×

3M 78469, Cubitron II Depressed Center Grinding Wheel, T27, 4 in x 1/4 in x 3/8 in, 7100086893, 20 per case

20 × $10.14

3M 78469, Cubitron II Depressed Center Grinding Wheel, T27, 4 in x 1/4 in x 3/8 in, 7100086893, 20 per case

20 × $10.14 -

×

Dynabrade 78033 1-1/2" W x 30" L Coarse NWN DynaBrite Belt, 10/pack

10 × $15.37

Dynabrade 78033 1-1/2" W x 30" L Coarse NWN DynaBrite Belt, 10/pack

10 × $15.37 -

×

Dynabrade 78425 4-1/2" Dia. x 3/8" Coarse DynaBrite Surface Conditioning Disc, 25/pack

25 × $6.23

Dynabrade 78425 4-1/2" Dia. x 3/8" Coarse DynaBrite Surface Conditioning Disc, 25/pack

25 × $6.23

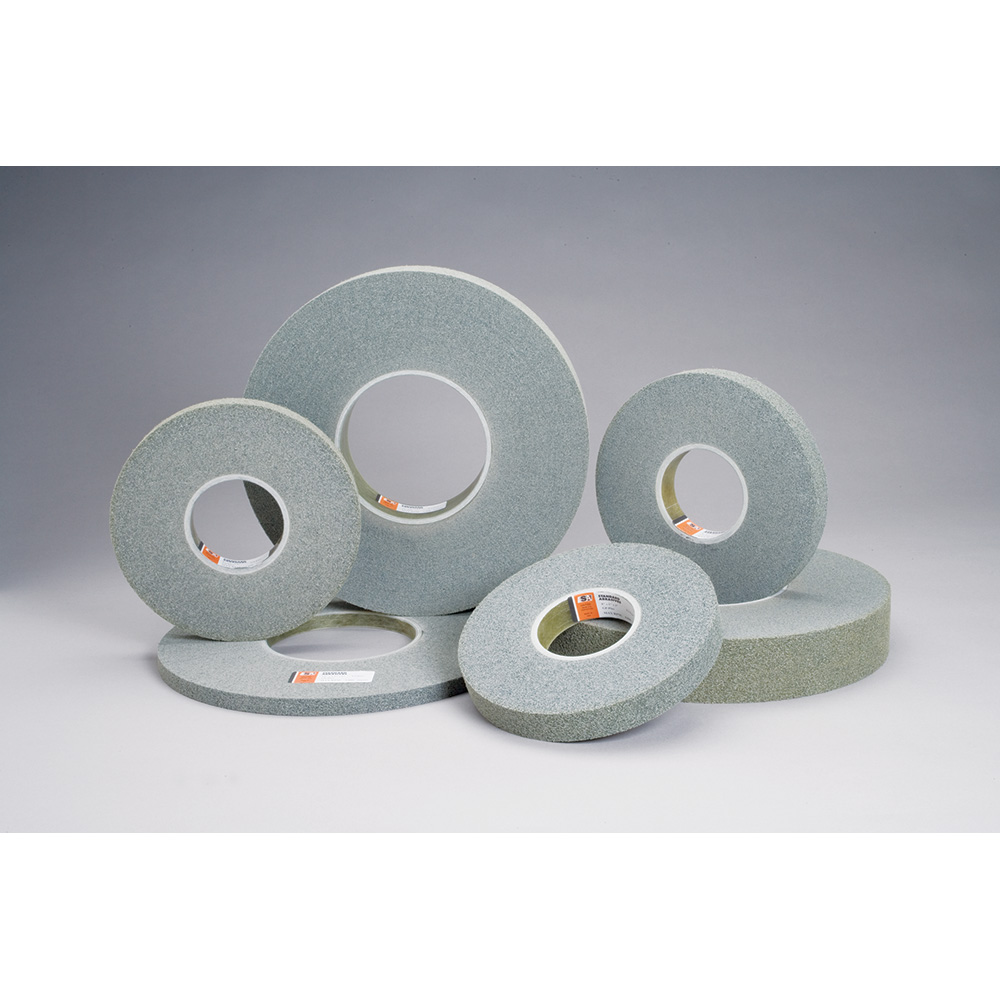

Standard Abrasives 851133, LDW Wheel, 6 in x 1 in x 1 in 6S FIN, 7000047105

$86.54

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.