-

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

500 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

500 × $4.14 -

×

3M 00254, Scotch-Brite Clean and Finish Roll, 12" x 30ft, CF-RL, Talc, 7000045859

1 × $345.52

3M 00254, Scotch-Brite Clean and Finish Roll, 12" x 30ft, CF-RL, Talc, 7000045859

1 × $345.52 -

×

Dynabrade 21432 ND220, Vane 5/Pack

1 × $21.89

Dynabrade 21432 ND220, Vane 5/Pack

1 × $21.89 -

×

3M 54257, Full Facepiece Reusable Respirator 7800S-S, Small, Silicone, 7000126199

1 × $492.69

3M 54257, Full Facepiece Reusable Respirator 7800S-S, Small, Silicone, 7000126199

1 × $492.69 -

×

Insize 7101-400A, DIGITAL HORIZONTAL SCALE, 16"/400mm, 6928640321634

1 × $293.74

Insize 7101-400A, DIGITAL HORIZONTAL SCALE, 16"/400mm, 6928640321634

1 × $293.74 -

×

Dynabrade 11253 Contact Arm Assy

1 × $525.64

Dynabrade 11253 Contact Arm Assy

1 × $525.64 -

×

Insize 1179-600, DIGITAL RTJ RING GROOVE CALIPER, inside diameter of RTJ ring groove .4-24"/10-600mm, outside diameter of RTJ ring groove 1-24"/25-600mm, 6928640302572

1 × $903.74

Insize 1179-600, DIGITAL RTJ RING GROOVE CALIPER, inside diameter of RTJ ring groove .4-24"/10-600mm, outside diameter of RTJ ring groove 1-24"/25-600mm, 6928640302572

1 × $903.74 -

×

Dynabrade 54947 Spring, Throttle Ball

1 × $4.28

Dynabrade 54947 Spring, Throttle Ball

1 × $4.28 -

×

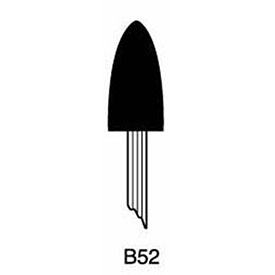

Dynabrade 78709 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46

Dynabrade 78709 3/8" x 3/4"-B52 Dynacut A/O Mounted Point, Vitrified, 5/pack

5 × $1.46 -

×

3M 80176, Cloth Belt 777F, 50 YF-weight, 6 in x 48 in, Film-lok, Single-flex, 7010307734, 20 per case

20 × $34.29

3M 80176, Cloth Belt 777F, 50 YF-weight, 6 in x 48 in, Film-lok, Single-flex, 7010307734, 20 per case

20 × $34.29 -

×

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $871.15

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $871.15 -

×

Insize 7101-800A, DIGITAL HORIZONTAL SCALE, 32"/800mm, 6928640321665

1 × $694.91

Insize 7101-800A, DIGITAL HORIZONTAL SCALE, 32"/800mm, 6928640321665

1 × $694.91 -

×

Insize 7101-600A, DIGITAL HORIZONTAL SCALE, 24"/600mm, 6928640321658

1 × $464.43

Insize 7101-600A, DIGITAL HORIZONTAL SCALE, 24"/600mm, 6928640321658

1 × $464.43 -

×

Dynabrade 78127 3" Dia. Medium NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $3.64

Dynabrade 78127 3" Dia. Medium NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $3.64

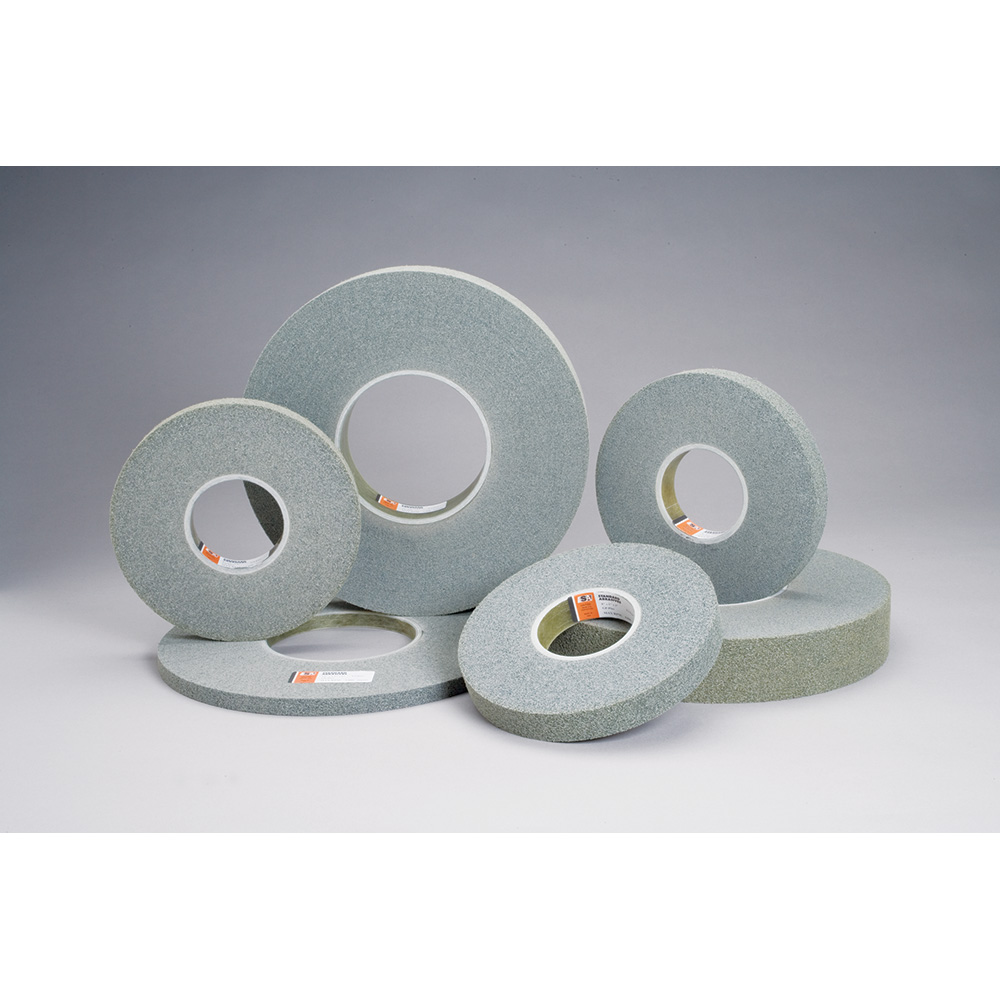

Standard Abrasives 851133, LDW Wheel, 6 in x 1 in x 1 in 6S FIN, 7000047105

$86.54

Factory Stock, 7-10 Day Leadtime

The Standard Abrasives Light Deburring Wheel finishes and deburrs parts with critical tolerances and may be used on automated equipment, straight shaft stationary and portable tools as well as feed-through machines.