-

×

Dynabrade 51756 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

1 × $603.00

Dynabrade 51756 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 35,000 RPM, 1/8" Collet

1 × $603.00 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00 -

×

3M 16583, Accuspray Atomizing Head, Green, 1.3 mm, 7010309279

10 × $10.67

3M 16583, Accuspray Atomizing Head, Green, 1.3 mm, 7010309279

10 × $10.67 -

×

Dynabrade 96101 Dynabrade Air Lube 10W/NR 24 Per Box

1 × $385.42

Dynabrade 96101 Dynabrade Air Lube 10W/NR 24 Per Box

1 × $385.42 -

×

Dynabrade 51862 .4 hp Trim Router (Complete), 30,000 RPM, 1/4 Collet

1 × $714.00

Dynabrade 51862 .4 hp Trim Router (Complete), 30,000 RPM, 1/4 Collet

1 × $714.00 -

×

Dynabrade 90872 2" Dia. Coarse NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89

Dynabrade 90872 2" Dia. Coarse NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.89 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21 -

×

Dynabrade 51705 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 3/32" Collet

1 × $558.00

Dynabrade 51705 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 50,000 RPM, 3/32" Collet

1 × $558.00 -

×

Dynabrade 51731 .1 hp Straight-Line Pencil Grinder, 60,000 RPM, 1/8" Collet

1 × $634.00

Dynabrade 51731 .1 hp Straight-Line Pencil Grinder, 60,000 RPM, 1/8" Collet

1 × $634.00 -

×

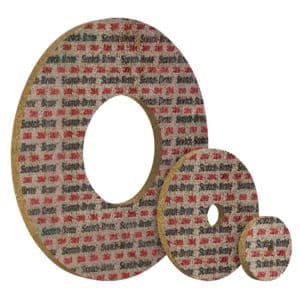

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70 -

×

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78

Dynabrade 95842 Dynabrade Air Lube 10W/NR, 1 Pint

1 × $25.78 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67

3M 22409, Roloc Disc 361F, P120 XF-weight, TR, 1-1/2 in, Die R150S, 7000045103

500 × $0.67 -

×

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 20u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 20u

12 × $7.60 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51 -

×

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

1 × $25.96

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

1 × $25.96 -

×

3M 62795, Polyurethane Adhesive Sealant 550FC Fast Cure, Black, 310 mL Cartridge, 7100001803, 12/Case

12 × $11.11

3M 62795, Polyurethane Adhesive Sealant 550FC Fast Cure, Black, 310 mL Cartridge, 7100001803, 12/Case

12 × $11.11 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43 -

×

3M 00550, DynatronAuto Seam Sealer Caulk, 550, Grey, 12 oz, 7000125068, 12 per case

12 × $16.71

3M 00550, DynatronAuto Seam Sealer Caulk, 550, Grey, 12 oz, 7000125068, 12 per case

12 × $16.71 -

×

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

10 × $2.70

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

10 × $2.70

Standard Abrasives 724277, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 2 Ply x 8-32, 7010368699

$6.64

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.