-

×

3M 83759, High Performance Industrial Plastic Adhesive 4693, Light Amber, 1 Quart Can, 7000046574, 12/case

12 × $58.11

3M 83759, High Performance Industrial Plastic Adhesive 4693, Light Amber, 1 Quart Can, 7000046574, 12/case

12 × $58.11 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

25 × $1.98

Dynabrade 78176 2" Dia. Medium NWN VT DynaBrite TR Locking-Type Disc, 25/pack

25 × $1.98 -

×

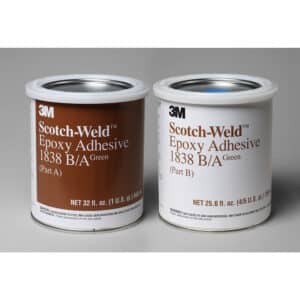

3M 20152, Scotch-Weld Epoxy Adhesive 1838, Green, Part B/A , 1 Quart Kit, 7000046340, 6/case

6 × $333.22

3M 20152, Scotch-Weld Epoxy Adhesive 1838, Green, Part B/A , 1 Quart Kit, 7000046340, 6/case

6 × $333.22 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00 -

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71 -

×

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $4.48

Dynabrade 78128 3" Dia. Coarse NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $4.48 -

×

Norton 66261014793 - 3" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc, 80 Each

80 × $3.80

Norton 66261014793 - 3" Medium Grade Aluminum Oxide Bear-Tex Speed-Lok High Strength Maroon TR Non-Woven Abrasive Disc, 80 Each

80 × $3.80 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

Dynabrade 78127 3" Dia. Medium NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $3.91

Dynabrade 78127 3" Dia. Medium NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $3.91

Standard Abrasives 724277, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 2 Ply x 8-32, 7010368699

$6.64

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.