-

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

80 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

80 × $11.06 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

6 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

6 × $43.00 -

×

Dynabrade 98269 1/2" Female Coupler

1 × $56.65

Dynabrade 98269 1/2" Female Coupler

1 × $56.65 -

×

3M 41597, Polyurethane Adhesive Sealant 560, Black, 310 mL Cartridge, 7100005901, 12/Case

12 × $14.64

3M 41597, Polyurethane Adhesive Sealant 560, Black, 310 mL Cartridge, 7100005901, 12/Case

12 × $14.64 -

×

3M 14895, Cloth Belt 777F, 80 YF-weight, 1 in x 42 in, Film-lok, Single-flex, 7010299926, 200 per case

200 × $4.46

3M 14895, Cloth Belt 777F, 80 YF-weight, 1 in x 42 in, Film-lok, Single-flex, 7010299926, 200 per case

200 × $4.46 -

×

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51

Dynabrade 11684 Dynabelter Contact Arm Assembly 4" DIA X 5/8" W., 40 Duro Serrated

1 × $438.51 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

2 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

2 × $80.58 -

×

Dynabrade 94980 1/4" Composite-Style Coupler, 1/4" Male

1 × $38.51

Dynabrade 94980 1/4" Composite-Style Coupler, 1/4" Male

1 × $38.51 -

×

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

3 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

3 × $2,225.47 -

×

3M 01335, PSA Cloth Disc 348D, 40 X-weight, 3 in x NH, Die 300V, 7000118878

200 × $1.01

3M 01335, PSA Cloth Disc 348D, 40 X-weight, 3 in x NH, Die 300V, 7000118878

200 × $1.01 -

×

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

1 × $4.57 -

×

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

3 × $6,424.71

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

3 × $6,424.71 -

×

3M 29823, Sanding Screen, 100 Grit, 20 in x NH, 7100160246

12 × $9.25

3M 29823, Sanding Screen, 100 Grit, 20 in x NH, 7100160246

12 × $9.25 -

×

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21

Standard Abrasives 701149, PSA A/O Disc, 1 in x NH, 240, 7010370103

100 × $0.21 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50 -

×

3M 20932, PSA Cloth Disc 348D, 80 X-weight, 1 in x NH, Die 100N, 7000118914

500 × $0.40

3M 20932, PSA Cloth Disc 348D, 80 X-weight, 1 in x NH, Die 100N, 7000118914

500 × $0.40 -

×

3M 04229, Scotch-Brite Hand Pad 7447B, HP-HP, A/O Very Fine, 6 in x 9 in, 7000027560, 60 ea/Case

1 × $77.93

3M 04229, Scotch-Brite Hand Pad 7447B, HP-HP, A/O Very Fine, 6 in x 9 in, 7000027560, 60 ea/Case

1 × $77.93 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $2,712.00 -

×

Dynabrade 95745 1/4" NPT Speed Regulator

1 × $85.81

Dynabrade 95745 1/4" NPT Speed Regulator

1 × $85.81 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

2 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

2 × $746.76 -

×

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23

Dynabrade 95843 Dynabrade Air Lube 10W/NR, 1 Gallon

1 × $109.23 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M 94717, Cubitron ll Cloth Belt 947A, 80+ X-weight, 1 in x 30 in, Fabri-lok, Single-flex, 7010294445, 200 per case

200 × $3.73

3M 94717, Cubitron ll Cloth Belt 947A, 80+ X-weight, 1 in x 30 in, Fabri-lok, Single-flex, 7010294445, 200 per case

200 × $3.73 -

×

3M 20909, PSA Cloth Disc 348D, 80 X-weight, 2 in x NH, Die 200P, 7000118873

200 × $0.78

3M 20909, PSA Cloth Disc 348D, 80 X-weight, 2 in x NH, Die 200P, 7000118873

200 × $0.78 -

×

3M 29850, Sanding Screen, 120 Grit, 15 in x NH, 7100160830

12 × $4.47

3M 29850, Sanding Screen, 120 Grit, 15 in x NH, 7100160830

12 × $4.47 -

×

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00

Dynabrade 95821 Dynabrade Air Lube 10W/NR, 4oz Bottle

1 × $18.00 -

×

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22 -

×

3M 71878, Flexible Diamond Hand File 6210J, Yellow 18, N40, NO 1, 7000082156, 10 per case

1 × $95.83

3M 71878, Flexible Diamond Hand File 6210J, Yellow 18, N40, NO 1, 7000082156, 10 per case

1 × $95.83 -

×

3M 25124, Scotch-Weld Threadlocker TL42, Blue, 1 L Bottle, 7010310189, 1/case

1 × $319.64

3M 25124, Scotch-Weld Threadlocker TL42, Blue, 1 L Bottle, 7010310189, 1/case

1 × $319.64 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

3M 33501, Sanding Respirator, 03201, 7000120129, 2 per pack

12 × $6.12

3M 33501, Sanding Respirator, 03201, 7000120129, 2 per pack

12 × $6.12 -

×

3M 64422, Nozzles for Two-Component Adhesive Sealant Applicator 400A-2K, 7000144625

36 × $2.82

3M 64422, Nozzles for Two-Component Adhesive Sealant Applicator 400A-2K, 7000144625

36 × $2.82 -

×

3M 29831, Sanding Screen, 180 Grit, 18 in x NH, 7100160238

12 × $5.83

3M 29831, Sanding Screen, 180 Grit, 18 in x NH, 7100160238

12 × $5.83 -

×

3M 20928, PSA Cloth Disc 348D, P180 X-weight, 1 in x NH, Die 100N, 7000118917

500 × $0.40

3M 20928, PSA Cloth Disc 348D, P180 X-weight, 1 in x NH, Die 100N, 7000118917

500 × $0.40 -

×

3M 08024, Adhesive Sealant 740 UV, Black, 290 mL Cartridge, 7100115542, 12 per case

12 × $16.25

3M 08024, Adhesive Sealant 740 UV, Black, 290 mL Cartridge, 7100115542, 12 per case

12 × $16.25 -

×

Dynabrade 51863 .7 hp Trim Router (Complete), 20,000 RPM, 1/4 Collet

1 × $779.00

Dynabrade 51863 .7 hp Trim Router (Complete), 20,000 RPM, 1/4 Collet

1 × $779.00 -

×

Insize ISY-100-27048, SUPPORT HEAD, nylon, 6928640395864

1 × $15.04

Insize ISY-100-27048, SUPPORT HEAD, nylon, 6928640395864

1 × $15.04 -

×

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

40 × $11.64

Norton 66261014936 3" DIA X 1/8" Thick, Bear-Tex NEX Rapid Blend Quick-Change Type III Non-Woven Unified Wheel, 40 Each

40 × $11.64

3M 29257, Scotch-Brite Metal Finishing Unitized Wheel, 6 in x 1/2 in x 1 in 5A MED, 7010366457

Discontinued, 3M Suggested Replacement-

| 7010329393 |

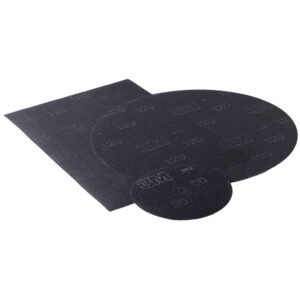

Our Scotch-Brite Metal Finishing Unitized Wheel combines the durability of cured open web with fast yet soft cutting action, rendering it a good wheel for finishing, blending and polishing, especially on hard-to-reach areas.

Good for Finishing, Blending and Polishing

The Scotch-Brite™ Metal Finishing Unitized Wheel is engineered by layering open web material, comprised of non-woven nylon fibers, aluminum oxide and resin, and compressing it. The compression enhances overall abrasive durability; it strengthens the wheel’s ability to swiftly and effectively tackle tough blending applications. Aluminum oxide mineral interspersed throughout the open web cuts sharp but leaves a fine, soft finish. Together, these attributes make Scotch-Brite™ Metal Finishing Unitized Wheel a good match for finishing, blending and polishing.

Typical applications for this Scotch-Brite™ wheel might include weld cleaning and blending in stainless steel tanks, finishing and blending builders hardware and generating a grained finish after weld blending. Unitized wheels may be used to blend and match #3 or #4 mill finishes on stainless steel and to create brushed or satin finishes on cutlery. On softer metals such as aluminum, copper and brass, they are used to blend out minor surface imperfections and handling marks while providing a decorative finish.

Durable and Aggressive

Customers choose Scotch-Brite™ wheels because of their ease of use and consistent results. Available in convolute and unitized designs, each of these wheel types offers unique benefits. Metal finishing unitized wheels offer the same finishing capability of metal finishing convolute wheel. However, the layered construction of unitized wheels makes them more aggressive and durable, slightly less conformable than convolute wheels. Additionally, unitized wheels are non-directional, so they can run clockwise or counterclockwise. The “edge” of the web becomes the cutting side, and the wheel is used with tools like inline sanders, bench motors, backstands and die grinders.

Scotch-Brite™ Unitized Wheel performance differences can be attributed to mineral (aggressiveness) and density (hardness). The combination of these two characteristics and subtle variations determine if the wheel will cut more aggressively or will be more durable and less conformable. Depending on their application, users can select the right combination for their unique project needs. Our Scotch-Brite™ Metal Finishing Unitized Wheels are available in small diameters and narrow widths. In essence, they provide durability and value for finishing of parts that are too narrow, tight or small to finish efficiently with wider width wheels, so you can still tackle those tough areas and achieve a fine finish.