-

×

Dynabrade 80510 Mini-Raptor 2 Vac Replacement Bags

1 × $46.00

Dynabrade 80510 Mini-Raptor 2 Vac Replacement Bags

1 × $46.00 -

×

Dynabrade 61203 RaptorVac Pneumatic DrumVac Kit, Single Operator, For Use With Tools

1 × $2,389.00

Dynabrade 61203 RaptorVac Pneumatic DrumVac Kit, Single Operator, For Use With Tools

1 × $2,389.00 -

×

Dynabrade 61201 RaptorVac Electric DrumVac Kit, Dual Operator, For Use With Tools

1 × $2,600.68

Dynabrade 61201 RaptorVac Electric DrumVac Kit, Dual Operator, For Use With Tools

1 × $2,600.68 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

Dynabrade 90872 2" Dia. Coarse NWN DynaBrite Locking-Type Disc, 25/pack

50 × $1.89

Dynabrade 90872 2" Dia. Coarse NWN DynaBrite Locking-Type Disc, 25/pack

50 × $1.89 -

×

Norton 66623335427, 2" Dia Vortex Rapid Prep Quick-Change Non-Woven Abrasive Disc, Medium Grade, 50 Each

100 × $1.70

Norton 66623335427, 2" Dia Vortex Rapid Prep Quick-Change Non-Woven Abrasive Disc, Medium Grade, 50 Each

100 × $1.70 -

×

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $43.25

Dynabrade 90875 2" Dia. Super Fine NWN DynaBrite Locking-Type Disc, 25/pack

25 × $43.25 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21

Dynabrade 78424 4-1/2" Dia. x 3/8" Medium DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21 -

×

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00 -

×

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

10 × $2.70

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

10 × $2.70 -

×

Norton 66261014921 - 2" X 1/8" 50 - 80 Grit Coarse Grade Aluminum Oxide Bear-Tex Speed-Lok Rapid Blend Gray TR Non-Woven Unified Wheel, 60 Each

60 × $6.44

Norton 66261014921 - 2" X 1/8" 50 - 80 Grit Coarse Grade Aluminum Oxide Bear-Tex Speed-Lok Rapid Blend Gray TR Non-Woven Unified Wheel, 60 Each

60 × $6.44 -

×

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00

Dynabrade 15420 Dynafile III Abrasive Belt Tool

1 × $1,012.00 -

×

Dynabrade 78127 3" Dia. Medium NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $3.91

Dynabrade 78127 3" Dia. Medium NWN VT DynaBrite Locking-Type Disc, 25/pack

25 × $3.91 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50 -

×

3M 13372, Scotch-Brite Star, 3 in A CRS LS, 7000120967

50 × $6.76

3M 13372, Scotch-Brite Star, 3 in A CRS LS, 7000120967

50 × $6.76

Refine Surfaces

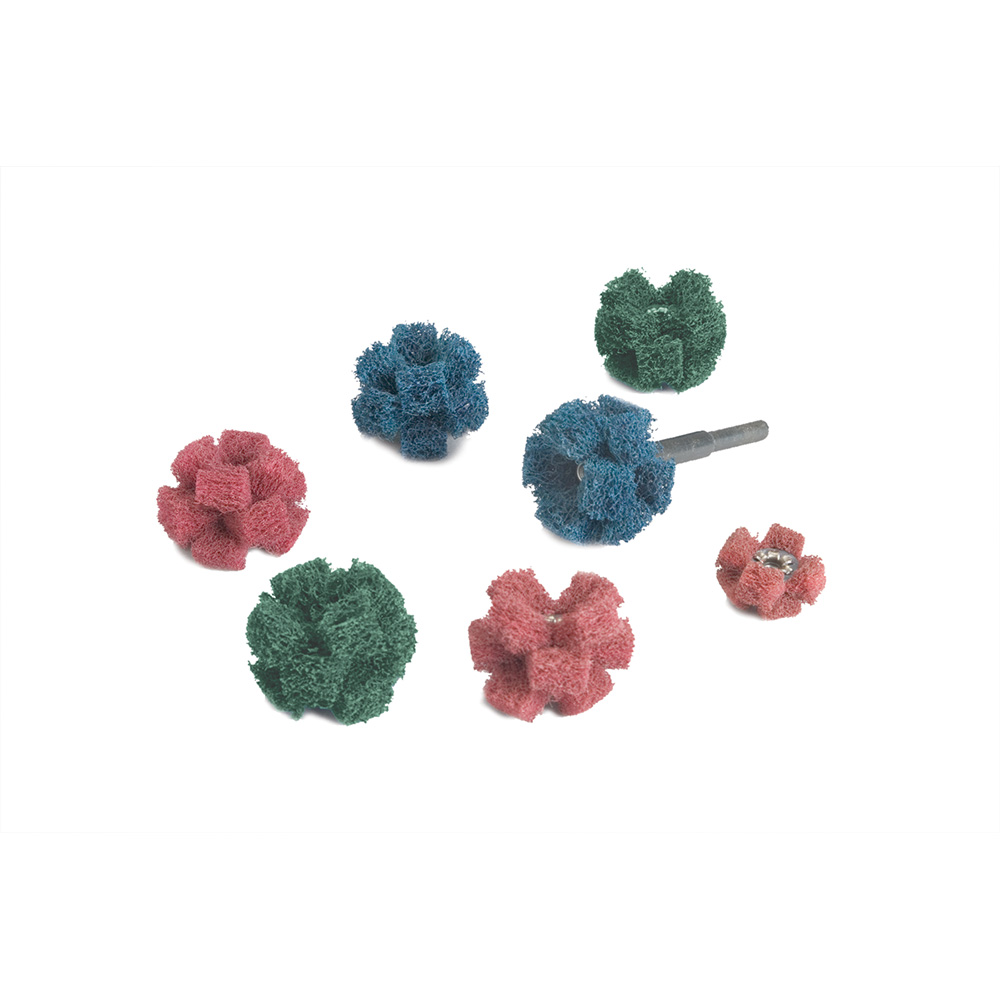

While discs or wheels may be unable to get inside a narrow pipe or tube, our Standard Abrasives™ Buff and Blend Cross Buff GP was designed to do just that. The abrasive fingers are spring-like and bend and move to accommodate the inner diameter of the workpiece. They refine the surface while maintaining the geometry of the part.

The abrasive material on Cross Buff GP is a great all-purpose material for cleaning and polishing. The mineral cuts sharp while still delivering a fine polish. Cross Buff GP comes in a range of grades from very fine (VFN) to coarse (CRS). Typically, very fine and fine grades are useful when a soft scratch pattern is desired, whereas a medium or coarse grade delivers a more aggressive scratch. Given its versatility, this abrasive is well-suited for removing surface oxidation, rust and surface coatings for part inspection, as well as surface preparation prior to coating. It can help remove corrosion on Steel Rule and Kirksite dies. It’s also great for polishing round and square tubing, valve spools, molds, dies and inside diameters of lifter bores, valve bodies and brake cylinders.

Attachment Styles

Standard Abrasives™ Buff and Blend Cross Buff GP fasten to a mandrel that in turn can be fastened to the power tool. The cross buffs attach to the mandrel with their 8-32 or 1/4-20 thread options. These versatile attachment options make it easier to securely mount and fasten the buff to the tool, helping to increase productivity.

Benefits of Open Web Abrasives

_In addition to the unique design of the Standard Abrasives™ Buff and Blend Cross Buff GP, the open web construction also adds a level of sponginess and flexibility. This open web material is created by combining nonwoven nylon strands and abrasive mineral with resin. Gaps between the nylon fibers allow unwanted swarf to escape, enhancing load resistance. As the abrasive is less likely to clog with debris, the mineral keeps cutting sharper, longer.

The open web material is waterproof and may be used with lubricants, which help to keep the abrasive running cool and wash away swarf. The load-resistant properties of the web, combined with the swarf-cleaning action of the lubricant, help to prevent workpiece contamination. As debris clears away, the likelihood of the disc smearing or blemishing the substrate decreases.