-

×

Dynabrade 51750 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $603.00

Dynabrade 51750 .1 hp Straight-Line Extension Pencil Grinder, Rear Exhaust, 60,000 RPM, 1/8" Collet

1 × $603.00 -

×

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40

3M 53914, Performance Plus Duct Tape 8979N Nuclear Red, 48 mm x 54.8 m 12.1 mil, 7000049014, 24/ case

1 × $33.40 -

×

Dynabrade 92118 1/4" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.15

Dynabrade 92118 1/4" W x 12" L 180 Grit A/O DynaCut Belt, 50/pack

50 × $1.15 -

×

Dynabrade 51708 .1 hp Straight-Line Pencil Grinder, 35,000 RPM, 3/32" Collet

1 × $558.00

Dynabrade 51708 .1 hp Straight-Line Pencil Grinder, 35,000 RPM, 3/32" Collet

1 × $558.00 -

×

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

400 × $0.95

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

400 × $0.95 -

×

3M 04029, Scotch-Brite Hand Pad 7447, HP-HP, A/O Very Fine, Maroon, 6 in x 9 in, 7000000728, 60/Case

1 × $82.43

3M 04029, Scotch-Brite Hand Pad 7447, HP-HP, A/O Very Fine, Maroon, 6 in x 9 in, 7000000728, 60/Case

1 × $82.43 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00 -

×

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71

3M™ 72122, Portable Compressed Air Filter and Regulator Panel 256-02-01, 100 cfm, 8 outlets, with Carbon Monoxide Monitor, 7000052147, 1 EA/Case

1 × $6,424.71 -

×

Insize 4209-6, LONG HANDLE TELESCOPING GAGE, 3-1/2 ~ 6", 6928640311581

1 × $16.55

Insize 4209-6, LONG HANDLE TELESCOPING GAGE, 3-1/2 ~ 6", 6928640311581

1 × $16.55 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00 -

×

3M 62816, Adhesive Sealant 760 UV, White, 600 mL Sausage Pack, 7000046609, 12/Case

12 × $26.69

3M 62816, Adhesive Sealant 760 UV, White, 600 mL Sausage Pack, 7000046609, 12/Case

12 × $26.69 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00

Dynabrade 11476 Dynabelter Abrasive Belt Tool, Heavy-Duty

1 × $1,721.00 -

×

3M 62606, Scotch-Weld Threadlocker TL42, Blue, 50 mL Bottle, 7100039193, 10/case

10 × $42.72

3M 62606, Scotch-Weld Threadlocker TL42, Blue, 50 mL Bottle, 7100039193, 10/case

10 × $42.72 -

×

3M 20230, Scotch-Seal Metal Sealant 2084, Silver, 5 Gallon Drum (Pail), 7000046344

5 × $198.10

3M 20230, Scotch-Seal Metal Sealant 2084, Silver, 5 Gallon Drum (Pail), 7000046344

5 × $198.10 -

×

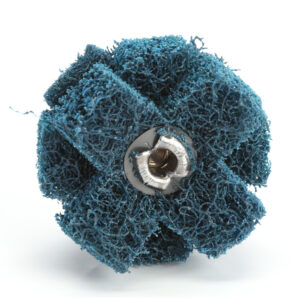

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

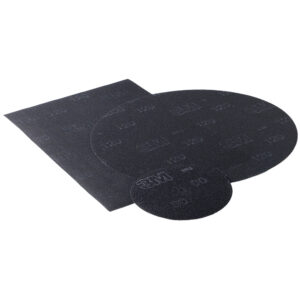

3M 29834, Sanding Screen, 100 Grit, 18 in x NH, 7100160819

12 × $7.56

3M 29834, Sanding Screen, 100 Grit, 18 in x NH, 7100160819

12 × $7.56 -

×

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33 -

×

3M 83539, Scotch Heavy Duty Packaging Tape Dispenser ST-181, Foam Handle with Retractable Blade, 7100288393

6 × $21.48

3M 83539, Scotch Heavy Duty Packaging Tape Dispenser ST-181, Foam Handle with Retractable Blade, 7100288393

6 × $21.48 -

×

Standard Abrasives 32953, PSA A/O Disc, 711880, 2 in x NH, 60, 7010310798

100 × $0.00

Standard Abrasives 32953, PSA A/O Disc, 711880, 2 in x NH, 60, 7010310798

100 × $0.00 -

×

Standard Abrasives 725012, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 2 Ply x 8-3, 7000046830

50 × $4.73

Standard Abrasives 725012, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 2 Ply x 8-3, 7000046830

50 × $4.73

Standard Abrasives 724276, Buff and Blend Circle Buff GP, 2 in x 2 Ply x 8-32 A MED, 7010330371

$6.64

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.