-

×

Standard Abrasives 882173, A/O Unitized Wheel, 821, 6 in x 1/4 in x 1/2 in, 7010330323

10 × $38.87

Standard Abrasives 882173, A/O Unitized Wheel, 821, 6 in x 1/4 in x 1/2 in, 7010330323

10 × $38.87 -

×

Standard Abrasives 725008, Buff and Blend Cross Buff HP, A/O Very Fine, 1 in x 3/8 in x 2 Ply x 8-32, 7000046829

50 × $3.13

Standard Abrasives 725008, Buff and Blend Cross Buff HP, A/O Very Fine, 1 in x 3/8 in x 2 Ply x 8-32, 7000046829

50 × $3.13 -

×

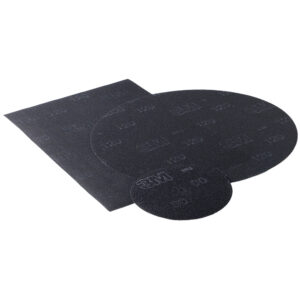

3M 29834, Sanding Screen, 100 Grit, 18 in x NH, 7100160819

12 × $7.56

3M 29834, Sanding Screen, 100 Grit, 18 in x NH, 7100160819

12 × $7.56 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

Standard Abrasives 725011, Buff and Blend Cross Buff HP, A/O VFN, 3/4 in x 3/8 in x 2 Ply x 8-32, 7000047134

50 × $3.75

Standard Abrasives 725011, Buff and Blend Cross Buff HP, A/O VFN, 3/4 in x 3/8 in x 2 Ply x 8-32, 7000047134

50 × $3.75 -

×

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52

3M 33349, 641WY 1/4" X 24", 220 Mesh Diamond Cloth Belt, 7010534919

15 × $9.52 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

3M 40465, VentureClad Heavy Duty Insulation Jacketing Tape 1579GCW, Silver, 30 in x 25 yd, 7100209735

1 × $778.18

3M 40465, VentureClad Heavy Duty Insulation Jacketing Tape 1579GCW, Silver, 30 in x 25 yd, 7100209735

1 × $778.18 -

×

3M 26584, Accuspray Refill Pack for PPS Series 2.0, Orange, 1.4 mm, 7100152954

5 × $6.63

3M 26584, Accuspray Refill Pack for PPS Series 2.0, Orange, 1.4 mm, 7100152954

5 × $6.63 -

×

3M 62615, Scotch-Weld Threadlocker TL90, Green, 10 mL Bottle, 7100039234, 10/case

10 × $13.32

3M 62615, Scotch-Weld Threadlocker TL90, Green, 10 mL Bottle, 7100039234, 10/case

10 × $13.32 -

×

3M 07148, Dual Airline Back-Mounted Breathing Tube SA-2500/07148(AAD), 7000002006, 1 EA/Case

1 × $151.32

3M 07148, Dual Airline Back-Mounted Breathing Tube SA-2500/07148(AAD), 7000002006, 1 EA/Case

1 × $151.32 -

×

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86 -

×

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

2 × $502.78

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

2 × $502.78 -

×

3M 16114, PPS Lid & Liner Kit, Mini (6 fl oz), 200 Micron Full

Diameter Filter, 50 Lids & Liners per kit, 7100054606

1 × $112.83

3M 16114, PPS Lid & Liner Kit, Mini (6 fl oz), 200 Micron Full

Diameter Filter, 50 Lids & Liners per kit, 7100054606

1 × $112.83 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06 -

×

Standard Abrasives 722809, PSA A/O Extra Disc, 5 in x NH, 60, 7010368721

50 × $1.22

Standard Abrasives 722809, PSA A/O Extra Disc, 5 in x NH, 60, 7010368721

50 × $1.22 -

×

Air Turbine Tools 310RDM - 6mm Router Hand Tool Series, 30,000RPM, 33433

1 × $950.00

Air Turbine Tools 310RDM - 6mm Router Hand Tool Series, 30,000RPM, 33433

1 × $950.00 -

×

Dynabrade 51702 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 3/32" Collet

1 × $558.00

Dynabrade 51702 .1 hp Straight-Line Pencil Grinder, Rear Exhaust, 60,000 RPM, 3/32" Collet

1 × $558.00 -

×

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38

3M 77558, Cubitron II Hookit Cloth Disc 947A, 77558, 40+ to 120+, 6 in x NH, Die 600Z, 7100232737

240 × $8.38 -

×

Standard Abrasives 725006, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046827

50 × $6.37

Standard Abrasives 725006, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046827

50 × $6.37

Standard Abrasives 724276, Buff and Blend Circle Buff GP, 2 in x 2 Ply x 8-32 A MED, 7010330371

$6.64

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.