-

×

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61

3M 22392, Roloc Disc 361F, 24 YF-weight, TR, 3 in, Die R300V, 7000045090

200 × $1.61 -

×

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00

3M™ 53797, Flexible Diamond Belt 6451J, 1/2" Dia x 18" L, M125 Micron, Type G, Pattern B2, 7010509272

3 × $43.00 -

×

3M 16831, Urethane Seam Sealer, 08361, Gray, 310 mL Foil Pack, 7000120461, 6 per case

6 × $28.47

3M 16831, Urethane Seam Sealer, 08361, Gray, 310 mL Foil Pack, 7000120461, 6 per case

6 × $28.47 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52 -

×

3M 83539, Scotch Heavy Duty Packaging Tape Dispenser ST-181, Foam Handle with Retractable Blade, 7100288393

6 × $21.48

3M 83539, Scotch Heavy Duty Packaging Tape Dispenser ST-181, Foam Handle with Retractable Blade, 7100288393

6 × $21.48 -

×

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $1,245.00

Dynabrade 13509 Dynastraight Finishing Tool, Rear Exhaust, 6,000 RPM, 5/8" (16 mm) or 1" (25 mm) Dia. Arbor

1 × $1,245.00 -

×

Dynabrade 51633 .1 hp Straight-Line Extension Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $634.00

Dynabrade 51633 .1 hp Straight-Line Extension Pencil Grinder, Central Vacuum, 1/8" Collet

1 × $634.00 -

×

3M 20905, PSA Cloth Disc 348D, P180 X-weight, 2 in x NH, Die 200P, 7000118876

200 × $0.82

3M 20905, PSA Cloth Disc 348D, P180 X-weight, 2 in x NH, Die 200P, 7000118876

200 × $0.82 -

×

3M 62605, Scotch-Weld Threadlocker TL42, Blue, 10 mL Bottle, 7100039190, 10/case

10 × $13.32

3M 62605, Scotch-Weld Threadlocker TL42, Blue, 10 mL Bottle, 7100039190, 10/case

10 × $13.32 -

×

3M 66608, Pomp Plus Probed Test Plugs 393-2017-50, 50 Pair/Case, 7010301959

1 × $100.28

3M 66608, Pomp Plus Probed Test Plugs 393-2017-50, 50 Pair/Case, 7010301959

1 × $100.28 -

×

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03

3M 77559, Cubitron II Hookit Cloth Disc 784F, 77559, 36+ to 120+, 5 in x NH, Die 500X, 7100232738

300 × $6.03 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M 98944, 3M Hand Tape Applicator, Large Block, 1 per case, 7010313229

1 × $44.95

3M 98944, 3M Hand Tape Applicator, Large Block, 1 per case, 7010313229

1 × $44.95 -

×

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33

3M 22404, Roloc Disc 361F, 80 YF-weight, TR, 3 in, Die R300V, 7000045100

200 × $1.33 -

×

Dynabrade 55034 3/8"-24 Female 5/8"-11 Male, 1-3/8" Length

1 × $53.82

Dynabrade 55034 3/8"-24 Female 5/8"-11 Male, 1-3/8" Length

1 × $53.82 -

×

Dynabrade 78182 3" Dia. Medium DynaBrite Locking-Type Disc, 25/pack

25 × $2.97

Dynabrade 78182 3" Dia. Medium DynaBrite Locking-Type Disc, 25/pack

25 × $2.97 -

×

Air Turbine Tools 310RSV - 1/4" Router Hand Tool Series, 40,000RPM, 33440

1 × $950.00

Air Turbine Tools 310RSV - 1/4" Router Hand Tool Series, 40,000RPM, 33440

1 × $950.00 -

×

3M 83539, Scotch Heavy Duty Packaging Tape Dispenser ST-181, Foam Handle withRetractable Blade, 7000028763

6 × $21.48

3M 83539, Scotch Heavy Duty Packaging Tape Dispenser ST-181, Foam Handle withRetractable Blade, 7000028763

6 × $21.48 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00 -

×

Standard Abrasives 725006, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046827

50 × $6.37

Standard Abrasives 725006, Buff and Blend Cross Buff HP, A/O VFN, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046827

50 × $6.37

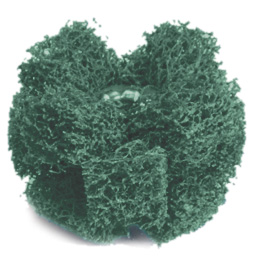

Standard Abrasives 724276, Buff and Blend Circle Buff GP, 2 in x 2 Ply x 8-32 A MED, 7010330371

$6.64

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.