-

×

3M 05068, Cubitron II Stikit Film Disc 775L, 400+, 5 in x NH, Linered w/Tab, Die 500X, 7100145364, 250 per case

250 × $1.04

3M 05068, Cubitron II Stikit Film Disc 775L, 400+, 5 in x NH, Linered w/Tab, Die 500X, 7100145364, 250 per case

250 × $1.04 -

×

Dynabrade 91425 1/4" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.07

Dynabrade 91425 1/4" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.07 -

×

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $27,619.39

Dynabrade 64404 36" W x 60" L (914 mm W x 1,524 mm L) Metal Capture Downdraft Table, 230 V (AC), Side Exhaust

1 × $27,619.39 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

Dynabrade 92119 1/4" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.07

Dynabrade 92119 1/4" W x 12" L 220 Grit A/O DynaCut Belt, 50/pack

50 × $1.07 -

×

3M 26016, PPS Series 2.0 Adapter, Type S9, 16 mm Male, 1.5 mm Thread, 7100135330

4 × $25.96

3M 26016, PPS Series 2.0 Adapter, Type S9, 16 mm Male, 1.5 mm Thread, 7100135330

4 × $25.96 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,509.65

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,509.65 -

×

3M 30204, Disposable Plastic Wheel Maskers, X-Large, 125 per box, 7000125076

1 × $73.46

3M 30204, Disposable Plastic Wheel Maskers, X-Large, 125 per box, 7000125076

1 × $73.46 -

×

Norton 66261013403 - 3" X 1/2" Extra Coarse Grade Silicon Carbide Bear-Tex Rapid Strip TR Stripping Disc, 10 Each

10 × $8.36

Norton 66261013403 - 3" X 1/2" Extra Coarse Grade Silicon Carbide Bear-Tex Rapid Strip TR Stripping Disc, 10 Each

10 × $8.36 -

×

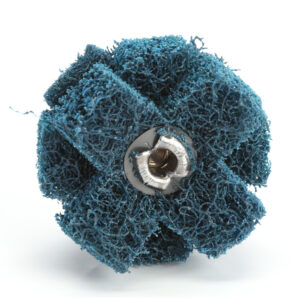

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

20 × $2.52

Dynabrade 92585 3-1/2" Dia. x Medium Hook-Face Surface Conditioning DynaBrite Disc, 10/pack

20 × $2.52 -

×

Dynabrade 91428 1/2" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.20

Dynabrade 91428 1/2" W x 12" L 60 Grit A/O DynaCut Belt, 50/pack

50 × $1.20 -

×

3M 62611, Scotch-Weld Threadlocker TL62, Red, 250 mL Bottle, 7100039195, 2/case

2 × $100.85

3M 62611, Scotch-Weld Threadlocker TL62, Red, 250 mL Bottle, 7100039195, 2/case

2 × $100.85 -

×

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14

3M 24049, Wetordry Cloth Disc 281W, P1000 YF-weight, 8 in x NH, Die 800JM, 7000045052

250 × $4.14 -

×

Dynabrade 94990 1/4" Female Composite-Style Coupler with 1/4" Male Plug Assembly

1 × $40.31

Dynabrade 94990 1/4" Female Composite-Style Coupler with 1/4" Male Plug Assembly

1 × $40.31 -

×

3M 16325, PPS Lid & Liner Kit, Large (28 fl oz), 125 Micron Full

Diameter Filter, 25 Lids & Liners per kit, 7100003284

1 × $70.50

3M 16325, PPS Lid & Liner Kit, Large (28 fl oz), 125 Micron Full

Diameter Filter, 25 Lids & Liners per kit, 7100003284

1 × $70.50 -

×

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95

3M 01326, PSA Cloth Disc 348D, P240 X-weight, 3 in x NH, Die 300V, 7000045069

200 × $0.95 -

×

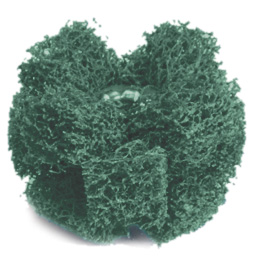

Dynabrade 78122 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.66

Dynabrade 78122 2" Dia. Medium NWN DynaBrite Locking-Type Disc, 25/pack

25 × $1.66 -

×

Standard Abrasives 727334, Buff and Blend Cross Buff HS, A/O Coarse, 1 in x 3/8 in x 2 Ply x 8-32, 7000047211

50 × $3.45

Standard Abrasives 727334, Buff and Blend Cross Buff HS, A/O Coarse, 1 in x 3/8 in x 2 Ply x 8-32, 7000047211

50 × $3.45

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.