-

×

3M 70894, 641WY 1/2" X 24", 100 Mesh Diamond Cloth Belt, 7010533228

1 × $19.01

3M 70894, 641WY 1/2" X 24", 100 Mesh Diamond Cloth Belt, 7010533228

1 × $19.01 -

×

3M 13800, Scotch-Brite Star, 1-1/2 in A VFN LS, 7000120969

100 × $3.24

3M 13800, Scotch-Brite Star, 1-1/2 in A VFN LS, 7000120969

100 × $3.24 -

×

3M 01335, PSA Cloth Disc 348D, 40 X-weight, 3 in x NH, Die 300V, 7000118878

200 × $1.01

3M 01335, PSA Cloth Disc 348D, 40 X-weight, 3 in x NH, Die 300V, 7000118878

200 × $1.01 -

×

3M 62604, Scotch-Weld Threadlocker TL42, Blue, 1 mL Pipette, 7100064043, 100/case

100 × $2.15

3M 62604, Scotch-Weld Threadlocker TL42, Blue, 1 mL Pipette, 7100064043, 100/case

100 × $2.15 -

×

3M 01875, Charge-Collection Solar Tape 3011, 2 mm x 1200 m, 7010312686

9 × $602.05

3M 01875, Charge-Collection Solar Tape 3011, 2 mm x 1200 m, 7010312686

9 × $602.05 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00 -

×

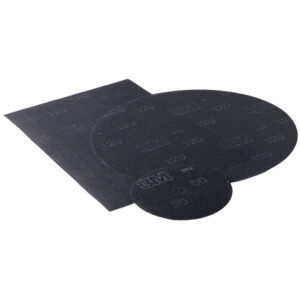

3M 07959, Sanding Screen, 100 Grit, 7-7/8 in x 3/16 in, 7100160279

40 × $1.60

3M 07959, Sanding Screen, 100 Grit, 7-7/8 in x 3/16 in, 7100160279

40 × $1.60 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06 -

×

Air Turbine Tools 310RDM - 1/4" Router Hand Tool Series, 25,000RPM, 33422

1 × $950.00

Air Turbine Tools 310RDM - 1/4" Router Hand Tool Series, 25,000RPM, 33422

1 × $950.00 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00 -

×

ACS CX1250 Diamond Belt, 1/2" X 24" 74u

12 × $7.60

ACS CX1250 Diamond Belt, 1/2" X 24" 74u

12 × $7.60 -

×

3M 62612, Scotch-Weld Threadlocker TL71, Red, 10 mL Bottle, 7100039197, 10/case

10 × $13.32

3M 62612, Scotch-Weld Threadlocker TL71, Red, 10 mL Bottle, 7100039197, 10/case

10 × $13.32 -

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52 -

×

Standard Abrasives 727399, Buff and Blend Cross Buff HS, A/O Medium, 2 in x 3/4 in x 2 Ply x 1/4-20, 7000047137

25 × $7.02

Standard Abrasives 727399, Buff and Blend Cross Buff HS, A/O Medium, 2 in x 3/4 in x 2 Ply x 1/4-20, 7000047137

25 × $7.02

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.