-

×

3M 16553, Scotch-Brite Extra Duty Hand Pad 6444, 6 in x 9 in, 7000028548, 60/Case

1 × $100.58

3M 16553, Scotch-Brite Extra Duty Hand Pad 6444, 6 in x 9 in, 7000028548, 60/Case

1 × $100.58 -

×

3M 29840, Sanding Screen, 100 Grit, 17 in x NH, 7100160821

12 × $7.56

3M 29840, Sanding Screen, 100 Grit, 17 in x NH, 7100160821

12 × $7.56 -

×

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00

Dynabrade 40320 Dynafile II Abrasive Belt Tool

1 × $722.00 -

×

Standard Abrasives 840037, Quick Change Surface Conditioning GP Disc, A/O Coarse, TSM, Brown, 3/4 in, QS75KM, 7000121646, 50/case

50 × $0.84

Standard Abrasives 840037, Quick Change Surface Conditioning GP Disc, A/O Coarse, TSM, Brown, 3/4 in, QS75KM, 7000121646, 50/case

50 × $0.84 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

3M 01335, PSA Cloth Disc 348D, 40 X-weight, 3 in x NH, Die 300V, 7000118878

200 × $1.01

3M 01335, PSA Cloth Disc 348D, 40 X-weight, 3 in x NH, Die 300V, 7000118878

200 × $1.01 -

×

3M 62611, Scotch-Weld Threadlocker TL62, Red, 250 mL Bottle, 7100039195, 2/case

2 × $100.85

3M 62611, Scotch-Weld Threadlocker TL62, Red, 250 mL Bottle, 7100039195, 2/case

2 × $100.85 -

×

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00

Dynabrade 53533 Cone or Plug Grinder (Triple Extension)

1 × $1,569.00 -

×

3M 94008, Scotch Super Glue Gel in Precision Applicator, AD125, .14 oz (4 g), 7100035277

36 × $2.42

3M 94008, Scotch Super Glue Gel in Precision Applicator, AD125, .14 oz (4 g), 7100035277

36 × $2.42 -

×

3M 62799, Polyurethane Adhesive Sealant 550FC Fast Cure, Gray, 310 mL Cartridge, 7000121486, 12/Case

12 × $11.11

3M 62799, Polyurethane Adhesive Sealant 550FC Fast Cure, Gray, 310 mL Cartridge, 7000121486, 12/Case

12 × $11.11 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60 -

×

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

1 × $25.96

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

1 × $25.96 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

40 × $11.06 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

18 × $9.52 -

×

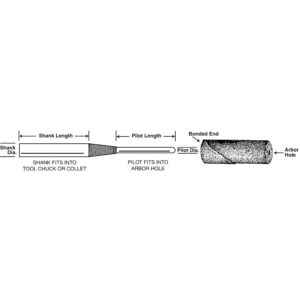

Standard Abrasives 710870, Cartridge Roll Mandrel, 1/8 in x 1/2 in x 1/4 in x 1-1/4 in x 2-1/4 in CM-7, 7000121794

5 × $4.71

Standard Abrasives 710870, Cartridge Roll Mandrel, 1/8 in x 1/2 in x 1/4 in x 1-1/4 in x 2-1/4 in CM-7, 7000121794

5 × $4.71 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51 -

×

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50

Norton 66254414832 - 3" X 1/4" X 1/4" Vortex Rapid Blend Unified Wheel, 5am U2305, 40 Each

40 × $11.50 -

×

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

1 × $502.78

3M™ 72016, Remote Alarm & Strobe 529-05-20, Audible, 7000131708, 1 EA/Case

1 × $502.78 -

×

Standard Abrasives 725011, Buff and Blend Cross Buff HP, A/O VFN, 3/4 in x 3/8 in x 2 Ply x 8-32, 7000047134

50 × $3.75

Standard Abrasives 725011, Buff and Blend Cross Buff HP, A/O VFN, 3/4 in x 3/8 in x 2 Ply x 8-32, 7000047134

50 × $3.75

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.