-

×

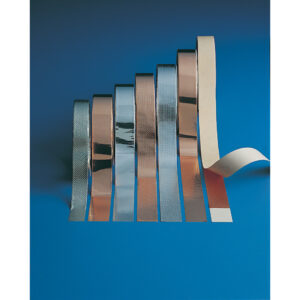

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M 01332, PSA Cloth Disc 348D, 80 X-weight, 3 in x NH, Die 300V, 7000118881

200 × $0.90

3M 01332, PSA Cloth Disc 348D, 80 X-weight, 3 in x NH, Die 300V, 7000118881

200 × $0.90 -

×

Norton 66254489957 Wheel, Vortex-7am, 6" X 1/2" X 1" C2312 Nor VTME7 PH VTC+, 4 Each

4 × $84.19

Norton 66254489957 Wheel, Vortex-7am, 6" X 1/2" X 1" C2312 Nor VTME7 PH VTC+, 4 Each

4 × $84.19 -

×

3M 62607, Scotch-Weld Threadlocker TL42, Blue, 250 mL Bottle, 7100039192, 2/case

2 × $126.95

3M 62607, Scotch-Weld Threadlocker TL42, Blue, 250 mL Bottle, 7100039192, 2/case

2 × $126.95 -

×

3M 29842, Sanding Screen, 180 Grit, 16 in x NH, 7100160822

12 × $4.58

3M 29842, Sanding Screen, 180 Grit, 16 in x NH, 7100160822

12 × $4.58 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76 -

×

Standard Abrasives 722809, PSA A/O Extra Disc, 5 in x NH, 60, 7010368721

50 × $1.22

Standard Abrasives 722809, PSA A/O Extra Disc, 5 in x NH, 60, 7010368721

50 × $1.22 -

×

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

36 × $9.52

3M 71361, 641WY 1/4" X 24", 1200 Mesh Diamond Cloth Belt, 7010534916

36 × $9.52 -

×

Standard Abrasives 37446, PSA A/O Disc, 700595, 1-1/2 in x NH, 60, 7010331822

100 × $0.24

Standard Abrasives 37446, PSA A/O Disc, 700595, 1-1/2 in x NH, 60, 7010331822

100 × $0.24 -

×

3M 50216, Temflex Cotton Friction Tape 1755, 3/4 in x 82-1/2 ft, Black, 7010297809

60 × $10.08

3M 50216, Temflex Cotton Friction Tape 1755, 3/4 in x 82-1/2 ft, Black, 7010297809

60 × $10.08 -

×

3M 29829, Sanding Screen, 80 Grit, 19 in x NH, 7100160252

12 × $11.21

3M 29829, Sanding Screen, 80 Grit, 19 in x NH, 7100160252

12 × $11.21 -

×

3M 20230, Scotch-Seal Metal Sealant 2084, Silver, 5 Gallon Drum (Pail), 7000046344

5 × $198.10

3M 20230, Scotch-Seal Metal Sealant 2084, Silver, 5 Gallon Drum (Pail), 7000046344

5 × $198.10 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58 -

×

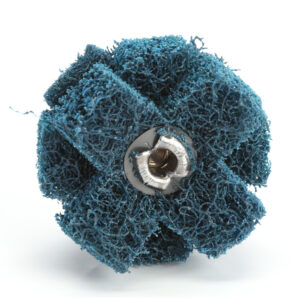

Standard Abrasives 727399, Buff and Blend Cross Buff HS, A/O Medium, 2 in x 3/4 in x 2 Ply x 1/4-20, 7000047137

25 × $7.02

Standard Abrasives 727399, Buff and Blend Cross Buff HS, A/O Medium, 2 in x 3/4 in x 2 Ply x 1/4-20, 7000047137

25 × $7.02 -

×

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06

3M™ 72010, Replacement Filter Kit 523-01-29, 7000056891, 1 EA/Case

1 × $500.06 -

×

Dynabrade 59339 Vacuum Cuff, 1", w/Groove

1 × $13.53

Dynabrade 59339 Vacuum Cuff, 1", w/Groove

1 × $13.53 -

×

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43

Dynabrade 95544 Gear Grease, 2.5oz. Tube

1 × $11.43 -

×

3M 49456, EMI Aluminum Foil Shielding Tape 1170, 2 in x 18 yd, 1170-2"X18YD, 7000132702

5 × $168.38

3M 49456, EMI Aluminum Foil Shielding Tape 1170, 2 in x 18 yd, 1170-2"X18YD, 7000132702

5 × $168.38 -

×

3M 26000, PPS Series 2.0 Spray Cup System Kit, Standard (22 fl oz, 650

mL), 200 Micron Filter, 7100134641

1 × $132.50

3M 26000, PPS Series 2.0 Spray Cup System Kit, Standard (22 fl oz, 650

mL), 200 Micron Filter, 7100134641

1 × $132.50 -

×

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26

3M™ 07011, Supplied Air Respirator Hose W-9435-50/07011(AAD), 7000005373, 1 EA/Case

1 × $274.26 -

×

3M 21221, Industrial Plastic Adhesive 4475, Clear, 1 Quart Can, 7000046573, 12/case

12 × $94.26

3M 21221, Industrial Plastic Adhesive 4475, Clear, 1 Quart Can, 7000046573, 12/case

12 × $94.26 -

×

Dynabrade 94960 1/4" Composite-Style Coupler, 1/4" Female

1 × $36.55

Dynabrade 94960 1/4" Composite-Style Coupler, 1/4" Female

1 × $36.55 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

20 × $12.65 -

×

Air Turbine Tools 310RSV - 1/4" Router Hand Tool Series, 25,000RPM, 33420

1 × $950.00

Air Turbine Tools 310RSV - 1/4" Router Hand Tool Series, 25,000RPM, 33420

1 × $950.00 -

×

Standard Abrasives 725005, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046826

50 × $6.37

Standard Abrasives 725005, Buff and Blend Cross Buff HS, A/O Medium, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7000046826

50 × $6.37

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.