-

×

3M 29829, Sanding Screen, 80 Grit, 19 in x NH, 7100160252

12 × $11.21

3M 29829, Sanding Screen, 80 Grit, 19 in x NH, 7100160252

12 × $11.21 -

×

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

2 × $2,712.00

Dynabrade 11477 Dynabelter Abrasive Belt Tool, Heavy-Duty

2 × $2,712.00 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76 -

×

3M 19076, E-A-R Classic Probed Test Plugs 393-2003-50, 50 EA/Case, 7000052882

1 × $101.11

3M 19076, E-A-R Classic Probed Test Plugs 393-2003-50, 50 EA/Case, 7000052882

1 × $101.11 -

×

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58

3M™ 17379, Versaflo™ Length Adjusting Breathing Tube BT-30, 7100009685, 1 EA/Case

1 × $80.58 -

×

3M 29834, Sanding Screen, 100 Grit, 18 in x NH, 7100160819

12 × $7.56

3M 29834, Sanding Screen, 100 Grit, 18 in x NH, 7100160819

12 × $7.56 -

×

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97

3M 11419, Roloc Disc 361F, P240 XF-weight, TR, 2 in, Die R200P, 7000045105

200 × $0.97 -

×

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47

3M™ 72787, Calibration Kit 529-04-48, Large, 7000052154, 1 EA/Case

1 × $2,225.47 -

×

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60

3M 11412, Roloc Disc 361F, 36 YF-weight, TR, 1 in, Die R100N, 7000045092

500 × $0.60 -

×

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

40 × $12.65

3M 87449 Silver Depressed Center Grinding Wheel, T27 Quick Change, 9 in x 1/4 in x 5/8-11 Center Hub Thread, 7010409732, 20 per case

40 × $12.65 -

×

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

120 × $11.06

3M 77197, Scotch-Brite™ Roloc™ Deburr and Finish PRO Unitized Wheel,TR, 3 in x 1/8 in x NH, 8C CRS+, 7100109130, 40/box

120 × $11.06 -

×

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18

3M 71358, 641WY 1/4" X 24", 600 Mesh Diamond Cloth Belt, 7010534894

1 × $9.18 -

×

3M 62615, Scotch-Weld Threadlocker TL90, Green, 10 mL Bottle, 7100039234, 10/case

10 × $13.32

3M 62615, Scotch-Weld Threadlocker TL90, Green, 10 mL Bottle, 7100039234, 10/case

10 × $13.32 -

×

Insize ISV-K6015, VIDEOSCOPE, lens diameter .236", cable length 60", 6940561973440

1 × $7,784.02

Insize ISV-K6015, VIDEOSCOPE, lens diameter .236", cable length 60", 6940561973440

1 × $7,784.02 -

×

3M 43061, Aura Particulate Respirator 9205+, N95, 7100232940, 440 ea/Case

1 × $480.11

3M 43061, Aura Particulate Respirator 9205+, N95, 7100232940, 440 ea/Case

1 × $480.11 -

×

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58

3M 11414, Roloc Disc 361F, P120 XF-weight, TR, 1 in, Die R100N, 7000045104

500 × $0.58 -

×

3M 64935, Scotch-Brite Hand Pad 7448 PRO, PO-HP, SiC Ultra Fine, 6 in x 9 in, 7100023340, 20/Carton

3 × $28.53

3M 64935, Scotch-Brite Hand Pad 7448 PRO, PO-HP, SiC Ultra Fine, 6 in x 9 in, 7100023340, 20/Carton

3 × $28.53 -

×

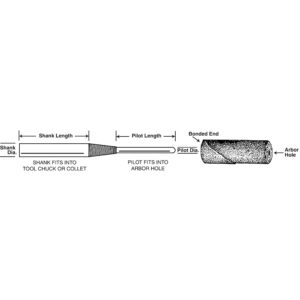

Standard Abrasives 701656, Cartridge RoII Mandrel, 3/16 in x 2 in x 1/4 in x 1-1/4 in x 4 in CM-18, 7010368730

5 × $5.56

Standard Abrasives 701656, Cartridge RoII Mandrel, 3/16 in x 2 in x 1/4 in x 1-1/4 in x 4 in CM-18, 7010368730

5 × $5.56 -

×

Dynabrade 78423 4-1/2" Dia. x 3/8" Very Fine DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21

Dynabrade 78423 4-1/2" Dia. x 3/8" Very Fine DynaBrite Surface Conditioning Disc, 25/pack

25 × $5.21 -

×

3M 62661, Scotch-Weld General Purpose Retaining Compound RT09, Green, 10 mL Bottle, 7100039228, 10/case

10 × $12.22

3M 62661, Scotch-Weld General Purpose Retaining Compound RT09, Green, 10 mL Bottle, 7100039228, 10/case

10 × $12.22 -

×

Insize ISF-S100-U, DIGITAL SPRING TESTERS, 22lbf, 6940561961331

1 × $4,073.00

Insize ISF-S100-U, DIGITAL SPRING TESTERS, 22lbf, 6940561961331

1 × $4,073.00 -

×

3M 08024, Adhesive Sealant 740 UV, Black, 290 mL Cartridge, 7100115542, 12 per case

12 × $16.25

3M 08024, Adhesive Sealant 740 UV, Black, 290 mL Cartridge, 7100115542, 12 per case

12 × $16.25 -

×

3M 23897, Cloth Belt 777F, 60 YF-weight, 1 in x 18 in, Fabri-lok, Full-flex, 7010307894, 200 per case

200 × $3.47

3M 23897, Cloth Belt 777F, 60 YF-weight, 1 in x 18 in, Fabri-lok, Full-flex, 7010307894, 200 per case

200 × $3.47 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22

Dynabrade 64350 26" W x 36" L (660 mm W x 914 mm L) Metal Capture Downdraft Station, 230 V (AC)

1 × $18,352.22 -

×

Standard Abrasives 725017, Buff and Blend Cross Buff GP, A/O Fine, 3/4 in x 3/8 in x 2 Ply x 8-32, 7010330367

50 × $2.88

Standard Abrasives 725017, Buff and Blend Cross Buff GP, A/O Fine, 3/4 in x 3/8 in x 2 Ply x 8-32, 7010330367

50 × $2.88 -

×

3M 08023, Adhesive Sealant 740 UV, White, 600 mL Sausage Pack, 7000000933, 12/Case

12 × $19.37

3M 08023, Adhesive Sealant 740 UV, White, 600 mL Sausage Pack, 7000000933, 12/Case

12 × $19.37 -

×

3M 47195, Polyurethane Construction Sealant 525, Gray, 600 mL Sausage Pack, 7100198003, 12/Case

12 × $12.12

3M 47195, Polyurethane Construction Sealant 525, Gray, 600 mL Sausage Pack, 7100198003, 12/Case

12 × $12.12 -

×

3M 11418, Roloc Disc 361F, P240 XF-weight, TR, 3 in, Die R300V, 7000045106

200 × $1.25

3M 11418, Roloc Disc 361F, P240 XF-weight, TR, 3 in, Die R300V, 7000045106

200 × $1.25 -

×

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

3 × $4.57

3M 21543, Scotch-Brite Roloc Clean and Strip XT Pro Extra Cut Disc, TR, 2 in x NH, A XCS, 7100179815, 60/box

3 × $4.57 -

×

Dynabrade 78380 3" Dia. x 1/2", Dyna Premium Rapid Strip TR Disc, 25/pack

25 × $10.49

Dynabrade 78380 3" Dia. x 1/2", Dyna Premium Rapid Strip TR Disc, 25/pack

25 × $10.49 -

×

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00

Dynabrade 14010 Dynafile Abrasive Belt Tool Versatility Kit

1 × $915.00 -

×

Insize 7261-300, INSIDE SPRING CALIPER, 12", 6928640319655

1 × $27.12

Insize 7261-300, INSIDE SPRING CALIPER, 12", 6928640319655

1 × $27.12 -

×

3M 08858 Scotch-Brite Surface Conditioning Belt, 1/2 in x 18 in, A CRS, 7000028455

20 × $6.58

3M 08858 Scotch-Brite Surface Conditioning Belt, 1/2 in x 18 in, A CRS, 7000028455

20 × $6.58 -

×

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86

3M 45714, Cubitron II Hookit Cloth Disc 947A, 120+ X-weight, 3 in x NH, D/F 3HL, Die 300BE, 7100113113

1 × $0.86 -

×

3M 06586, Marine, Adhesive, Sealant, 4000, UV, White, 400, mL, milliliter, Sausage, Pack, 7000121532, 12/ case

12 × $16.96

3M 06586, Marine, Adhesive, Sealant, 4000, UV, White, 400, mL, milliliter, Sausage, Pack, 7000121532, 12/ case

12 × $16.96 -

×

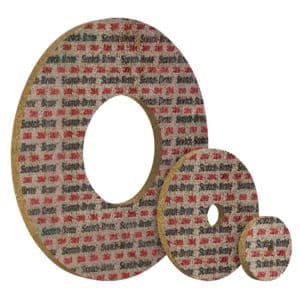

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70

3M 65033, Scotch-Brite Diamond Wheel, 645DC 6 in x 1/2 in x 1 in, 7010365574, Box of 3

1 × $531.70 -

×

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

1 × $25.96

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

1 × $25.96 -

×

Dynabrade 97567 1/4" Safety Coupler, Male

1 × $19.33

Dynabrade 97567 1/4" Safety Coupler, Male

1 × $19.33 -

×

3M 54358, Particulate Respirator 8247, R95, with Nuisance Level, Organic Vapor Relief, 7000002060, 120 EA/Case

1 × $494.49

3M 54358, Particulate Respirator 8247, R95, with Nuisance Level, Organic Vapor Relief, 7000002060, 120 EA/Case

1 × $494.49 -

×

3M 29822, Sanding Screen, 120 Grit, 20 in x NH, 7100160250

12 × $8.00

3M 29822, Sanding Screen, 120 Grit, 20 in x NH, 7100160250

12 × $8.00 -

×

Standard Abrasives 265006, Buff and Blend Cross Buff HS, A/O Medium, 3/4 in x 3/8 in x 2 Ply x 8-32, 7010330373

10 × $1.56

Standard Abrasives 265006, Buff and Blend Cross Buff HS, A/O Medium, 3/4 in x 3/8 in x 2 Ply x 8-32, 7010330373

10 × $1.56

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.