-

×

3M 03647, Scotch-Brite Edger Disc Pad, 7 in x .875 in, 7000133920

40 × $2.12

3M 03647, Scotch-Brite Edger Disc Pad, 7 in x .875 in, 7000133920

40 × $2.12 -

×

3M 05048, Cloth Belt 384F, 80+ XF-weight, 1 in x 12 in, Fabri-lok, Full-flex, 7100141432, 200 per case

200 × $1.57

3M 05048, Cloth Belt 384F, 80+ XF-weight, 1 in x 12 in, Fabri-lok, Full-flex, 7100141432, 200 per case

200 × $1.57 -

×

Insize 4209-2, LONG HANDLE TELESCOPING GAGE, 1/2 ~ 3/4", 6928640311543

1 × $14.30

Insize 4209-2, LONG HANDLE TELESCOPING GAGE, 1/2 ~ 3/4", 6928640311543

1 × $14.30 -

×

3M 97956, Super 77 CA Multipurpose Spray Adhesive, Low VOC <25%, Clear, 24 fl oz Can, 7100014109, 12/Case

12 × $16.85

3M 97956, Super 77 CA Multipurpose Spray Adhesive, Low VOC <25%, Clear, 24 fl oz Can, 7100014109, 12/Case

12 × $16.85 -

×

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37

3M™ 07012, Supplied Air Hose W-9435-100/07012(AAD), 100 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005375, 1 EA/Case

1 × $435.37 -

×

3M 64659, Scotch-Brite Durable Flex Hand Pad, MX-HP, A/O Very Fine, 4-1/2 in x 9 in, 7100042334, 25/Carton

4 × $27.08

3M 64659, Scotch-Brite Durable Flex Hand Pad, MX-HP, A/O Very Fine, 4-1/2 in x 9 in, 7100042334, 25/Carton

4 × $27.08 -

×

Dynabrade 51330 .7 hp Router, Front Exhaust, 20,000 RPM, 3/8"-24 Spindle

1 × $617.00

Dynabrade 51330 .7 hp Router, Front Exhaust, 20,000 RPM, 3/8"-24 Spindle

1 × $617.00 -

×

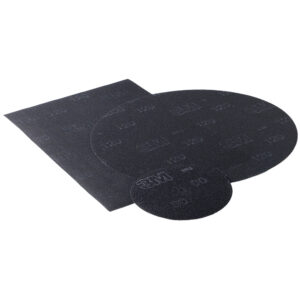

3M 29858, Sanding Screen, 80 grit, 12 in x 18 in, 7100161088

20 × $6.77

3M 29858, Sanding Screen, 80 grit, 12 in x 18 in, 7100161088

20 × $6.77 -

×

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30

3M 29611, 641WY 1/4" X 24", 100 Mesh Diamond Cloth Belt, 7010534832

15 × $7.30 -

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52 -

×

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67

3M 22407, Roloc Disc 361F, 80 YF-weight, TR, 1-1/2 in, Die R150S, 7000045099

500 × $0.67 -

×

3M 15060, Roloc + Button 7, 3/8 in Red, 7000045945

1 × $5.62

3M 15060, Roloc + Button 7, 3/8 in Red, 7000045945

1 × $5.62 -

×

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51

Dynabrade 10690 Filter/Regulator/Lubricator, FRL40, 1/2" NPTAssy.

1 × $388.51 -

×

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93

3M™ 07010, Supplied Air Respirator Hose W-9435-25/07010(AAD), 25 ft, 3/8 in ID, Industrial Interchange Fittings, High Pressure, 7000005374, 1 EA/Case

1 × $175.93 -

×

3M 14593, Scotch-Brite Cut and Polish Disc, 3" x 1-1/4" x 1/4" A Medium, D5, 7000045941, Box of 10

10 × $16.71

3M 14593, Scotch-Brite Cut and Polish Disc, 3" x 1-1/4" x 1/4" A Medium, D5, 7000045941, Box of 10

10 × $16.71 -

×

Dynabrade 79448 6" x 9" DynaBrite General Purpose Maroon Hand Pad, 20/box

20 × $28.56

Dynabrade 79448 6" x 9" DynaBrite General Purpose Maroon Hand Pad, 20/box

20 × $28.56 -

×

3M 16556, Scotch-Brite Light Duty Hand Pad 6448B, HP-HP, 6 in x 9 in, 7010329300, 60 ea/Case

1 × $83.29

3M 16556, Scotch-Brite Light Duty Hand Pad 6448B, HP-HP, 6 in x 9 in, 7010329300, 60 ea/Case

1 × $83.29 -

×

3M 13753, Scotch-Brite EXL Unitized Wheel, XL-UW, 8A Medium, 1 in x 1 in x 3/16 in, 7000148249

50 × $6.13

3M 13753, Scotch-Brite EXL Unitized Wheel, XL-UW, 8A Medium, 1 in x 1 in x 3/16 in, 7000148249

50 × $6.13 -

×

3M 08023, Adhesive Sealant 740 UV, White, 600 mL Sausage Pack, 7000000933, 12/Case

12 × $19.37

3M 08023, Adhesive Sealant 740 UV, White, 600 mL Sausage Pack, 7000000933, 12/Case

12 × $19.37 -

×

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series with Brake, 25,000RPM, 33425

1 × $975.00

Air Turbine Tools 310RSV - 6mm Router Hand Tool Series with Brake, 25,000RPM, 33425

1 × $975.00 -

×

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60

3M 11411, Roloc Disc 361F, 50 YF-weight, TR, 1 in, Die R100N, 7000045095

500 × $0.60 -

×

3M 29834, Sanding Screen, 100 Grit, 18 in x NH, 7100160819

12 × $7.56

3M 29834, Sanding Screen, 100 Grit, 18 in x NH, 7100160819

12 × $7.56 -

×

Standard Abrasives 724276, Buff and Blend Circle Buff GP, 2 in x 2 Ply x 8-32 A MED, 7010330371

25 × $6.64

Standard Abrasives 724276, Buff and Blend Circle Buff GP, 2 in x 2 Ply x 8-32 A MED, 7010330371

25 × $6.64

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.