-

×

3M 29837, Sanding Screen, 180 Grit, 17 in x NH, 7100160762

24 × $5.83

3M 29837, Sanding Screen, 180 Grit, 17 in x NH, 7100160762

24 × $5.83 -

×

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76

3M™ 17323, Versaflo™ Respiratory Helmet Assembly M-407, with Premium Visor and Flame Resistant Shroud, 7000002395, 1 EA/Case

1 × $746.76 -

×

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00

Dynabrade 53270 7" (180 mm) Dia. Right-Angle Disc Sander

1 × $1,585.00 -

×

3M 26018, PPS Series 2.0 Adapter, Type S11, 3/8 Male, 18 Thread NPS, 7100135942

1 × $25.96

3M 26018, PPS Series 2.0 Adapter, Type S11, 3/8 Male, 18 Thread NPS, 7100135942

1 × $25.96 -

×

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

1 × $25.96

3M 26022, PPS Series 2.0 Adapter, Type S12, 10 mm Male, 1.0 mm Thread, 7100135943

1 × $25.96 -

×

Dynabrade 01185 Vane Set (4pk)

1 × $26.54

Dynabrade 01185 Vane Set (4pk)

1 × $26.54 -

×

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52

3M 33780, 641WY 1/4" X 24", 400 Mesh Diamond Cloth Belt, 7010534915

15 × $9.52 -

×

3M 64935, Scotch-Brite Hand Pad 7448 PRO, PO-HP, SiC Ultra Fine, 6 in x 9 in, 7100023340, 20/Carton

3 × $28.53

3M 64935, Scotch-Brite Hand Pad 7448 PRO, PO-HP, SiC Ultra Fine, 6 in x 9 in, 7100023340, 20/Carton

3 × $28.53 -

×

Standard Abrasives 265006, Buff and Blend Cross Buff HS, A/O Medium, 3/4 in x 3/8 in x 2 Ply x 8-32, 7010330373

10 × $1.56

Standard Abrasives 265006, Buff and Blend Cross Buff HS, A/O Medium, 3/4 in x 3/8 in x 2 Ply x 8-32, 7010330373

10 × $1.56 -

×

3M 55886, Rugged Comfort 6581 / 55886 Head Harness Assembly, System Component, 7000128251, 20 EA/Case

1 × $185.12

3M 55886, Rugged Comfort 6581 / 55886 Head Harness Assembly, System Component, 7000128251, 20 EA/Case

1 × $185.12 -

×

3M 26580, Accuspray ONE Spray Gun System with PPS Series 2.0 Spray Cup System, 7100163226

2 × $348.22

3M 26580, Accuspray ONE Spray Gun System with PPS Series 2.0 Spray Cup System, 7100163226

2 × $348.22 -

×

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33

3M 22395, Roloc Disc 361F, 60 YF-weight, TR, 3 in, Die R300V, 7000045098

200 × $1.33 -

×

Air Turbine Tools 310RSV - 1/4" Router Hand Tool Series with Brake, 40,000RPM, 33444

1 × $975.00

Air Turbine Tools 310RSV - 1/4" Router Hand Tool Series with Brake, 40,000RPM, 33444

1 × $975.00 -

×

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76

3M™ 94275, Versaflo™ Gold Coated Tinted Over-Visor with UV/IR Protection M-967N, 70071696879, 1 EA/Case

1 × $192.76 -

×

Dynabrade 94993 1/4" Male Composite-Style Coupler with 1/4" Female Plug Assembly

1 × $42.43

Dynabrade 94993 1/4" Male Composite-Style Coupler with 1/4" Female Plug Assembly

1 × $42.43 -

×

3M 15913, Scotch-Brite Roloc Disc High Strength, TR, 2 in X NH A Medium, 7000000710

200 × $1.72

3M 15913, Scotch-Brite Roloc Disc High Strength, TR, 2 in X NH A Medium, 7000000710

200 × $1.72 -

×

3M 29858, Sanding Screen, 80 grit, 12 in x 18 in, 7100161088

20 × $6.77

3M 29858, Sanding Screen, 80 grit, 12 in x 18 in, 7100161088

20 × $6.77 -

×

3M 27468, EMI Copper Foil Shielding Tape 1181, 1 in x 18 yd (25,40 mm x 16,5 m), 7000132169

9 × $79.81

3M 27468, EMI Copper Foil Shielding Tape 1181, 1 in x 18 yd (25,40 mm x 16,5 m), 7000132169

9 × $79.81 -

×

3M 36880, Self-Stick Liquid Protection Fabric, Blue, 36 in x 300 ft, 7100169352

1 × $901.76

3M 36880, Self-Stick Liquid Protection Fabric, Blue, 36 in x 300 ft, 7100169352

1 × $901.76 -

×

Standard Abrasives 725001, Buff and Blend Cross Buff GP, A/O Medium, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7010330368

50 × $3.14

Standard Abrasives 725001, Buff and Blend Cross Buff GP, A/O Medium, 1-1/2 in x 1/2 in x 3 Ply x 8-32, 7010330368

50 × $3.14

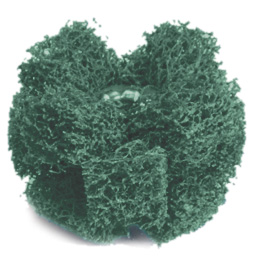

Standard Abrasives 724275, Buff and Blend Circle Buff GP, A/O Very Fine, 2 in x 1 Ply x 8-32, 7010368698

$4.57

Factory Stock, 7-10 Day Leadtime

A good starting point for many different light-duty applications, our Standard Abrasives Buff and Blend Circle Buff GP is a versatile non-woven product designed to lightly blend, clean, deburr and finish a variety of metals and leave a consistent final finish. The threaded eyelet secures the plies together to create a thicker edge and screws onto a mandrel for attachment to a handheld tool.